A prefabricated concrete post-grouting pile and its grouting process

A technology of prefabricated concrete and post-grouting piles, which is applied in sheet pile walls, foundation structure engineering, construction, etc., and can solve the problems of high material requirements for pre-embedded pipes, high temperature and high pressure for pre-embedded pipes, and easy deviation of grouting pipes, etc. problems, to achieve the effect of reducing the actual amount of piles used, reducing the effect of soil squeezing, and reducing the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

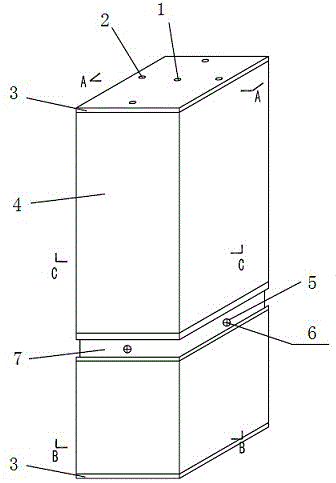

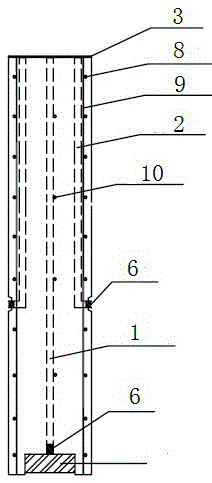

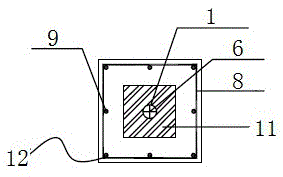

[0032] like Figure 1 to Figure 4 The prefabricated concrete post-grouting pile-compression pile mainly includes a post-grouting pile body 4, a steel cage skeleton 12, a flange 3, a post-grouting groove 7, a grouting hole 5, and a pile bottom filler 11 (rubber). The steel cage frame 12 is composed of longitudinal ribs 9 and surrounding ribs 8, flanges 3 are welded at both ends of the frame, a pile bottom post-grouting pipe 1 runs through the center of the frame, and four pipes run through four sides of the frame The post-grouting pipe 2 on the side of the pile is simultaneously poured with concrete and adopts a vibration forming process to form a solid prefabricated concrete post-grouting pile.

[0033] Among them, the longitudinal reinforcement adopts the mixed reinforcement of prestressed steel and non-prestressed steel; the surrounding reinforcement is a wire rod with a diameter of 6mm for construction; The plug 6; the flange 3 is a 20mm steel plate; the two end faces of ...

Embodiment 2

[0040] like Figure 5 to Figure 7 The shown prefabricated concrete post-grouting pile—uplift pile, runs through four grouting pipes on the four sides of the steel cage skeleton 12, and pours concrete at the same time and adopts a vibration molding process to form a solid precast concrete post. Grouting pile.

[0041] Among them, the longitudinal reinforcement is a mixed reinforcement of non-prestressed steel and glass fiber reinforcement (GFRP reinforcement); the surrounding reinforcement is a wire rod with a diameter of 8mm for construction; The plug 6; the flange 3 is a 24mm steel plate; the two end faces of the rear grouting pile are planes. The number of back grouting grooves is 4.

[0042] After sinking the above-mentioned uplift piles by using the prior art, the post-grouting pile body 4 is immediately grouted to ensure that the grouting slurry is fully bonded to the surrounding soil layer of the pile. Inject cement slurry through the grouting pipe or the specific sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com