A stacked supercapacitor with arbitrary shape on the same substrate and its preparation method

A technology of supercapacitors and arbitrary shapes, applied in the manufacture of hybrid/electric double layer capacitors, multiple hybrid/electric double layer capacitors, etc., can solve the problems that the shape of supercapacitors cannot be manufactured, achieve broad market application prospects, and simple equipment , The effect of simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

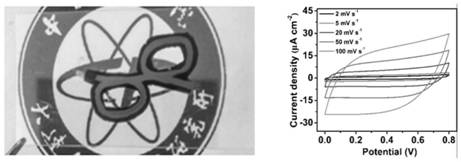

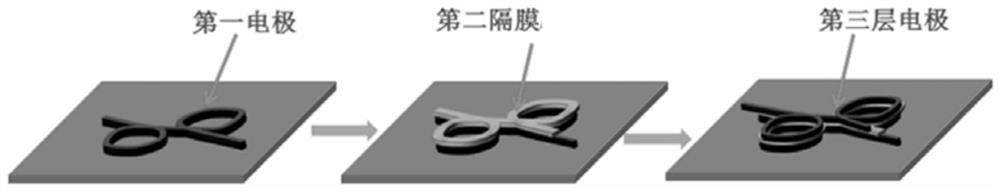

[0038] Electrochemical exfoliation of graphene dispersed in isopropanol (0.1 mg mL -1 ) and graphene oxide aqueous solution (1mgmL -1 ) is a raw material, and the average size of graphene oxide is 100nm in the present embodiment, and the spraying substrate is PET; figure 1 ) spraying thickness is the graphene electrode layer of 100nm, the airbrush caliber diameter of spraying is 0.3mm, and spraying nitrogen pressure is 0.05MPa, removes template 1, obtains a pole of intersection point linear supercapacitor; Then passes through intersection point linear template 2 (attached figure 1 ), spray the graphene oxide aqueous solution with a 0.2mm airbrush, the thickness of the graphene oxide membrane layer is 1.5 μm, and the spraying nitrogen pressure is 0.1M Pa, remove the template 2; on the graphene oxide membrane layer, pass through the cross point Linear template 1 Spray another electrode with the same thickness with a 0.3mm airbrush; then inject PVA / H 2 SO 4 , and then package...

Embodiment 2

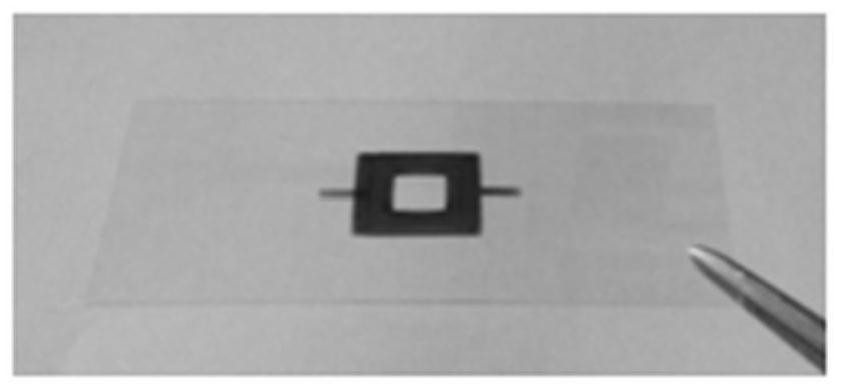

[0041] Electrochemical exfoliation of graphene dispersed in isopropanol (0.5 mg mL -1 ) and graphene oxide aqueous solution (1.5mgmL -1 ) is a raw material, and the average size of graphene oxide is 1 μm in the present embodiment, and the spraying base is PET; The graphene electrode layer that is 170nm is sprayed with a thickness by hollow square formwork 1, and the airbrush aperture diameter of spraying is 0.5mm, and spraying nitrogen pressure is 0.2MPa, remove the template 1 to obtain one pole of the hollow square supercapacitor; then pass through the hollow square template 2, spray the graphene oxide aqueous solution with a 0.3mm airbrush, the thickness of the graphene oxide diaphragm layer is 1 μm, and the spray nitrogen pressure is 0.1M Pa, remove the template 2; on the graphene oxide diaphragm layer, spray another electrode with the same thickness with a 0.5mm spray pen through the hollow square template 1; then inject PVA / H 2 SO 4 , and then encapsulated; that is, a h...

Embodiment 3

[0044] Reduced graphene oxide (2mg mL) dispersed in isopropanol -1 ) and graphene oxide aqueous solution (4mg mL -1 ) as a raw material, the average size of graphene oxide in the present embodiment is 1 μm, and the spraying substrate is PET; the graphene electrode layer whose thickness is 1 μm is sprayed by the letter “A” shape template 1, and the diameter of the spray pen diameter of spraying is 0.3mm, spraying The nitrogen pressure is 0.1MPa, and the template 1 is removed to obtain one pole of the letter "A"-shaped supercapacitor; then through the letter "A"-shaped template 2, the graphene oxide aqueous solution is sprayed with a 0.3mm spray pen, and the graphene oxide diaphragm layer The thickness is 2 μm, the spraying nitrogen pressure is 0.1M Pa, and the template 2 is removed; then on the graphene oxide diaphragm layer, another electrode with the same thickness is sprayed with a 0.3mm spray pen through the letter "A"-shaped template 1; then Inject PVA / H 2 SO 4 , and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com