Method for producing clay pot

A manufacturing method and technology of clay pots, applied in the direction of manufacturing tools, ceramic molding machines, molds, etc., can solve the problems of difficult control of external dimensions, large shrinkage and deformation, etc., and achieve the effect of easy control of external dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Now in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

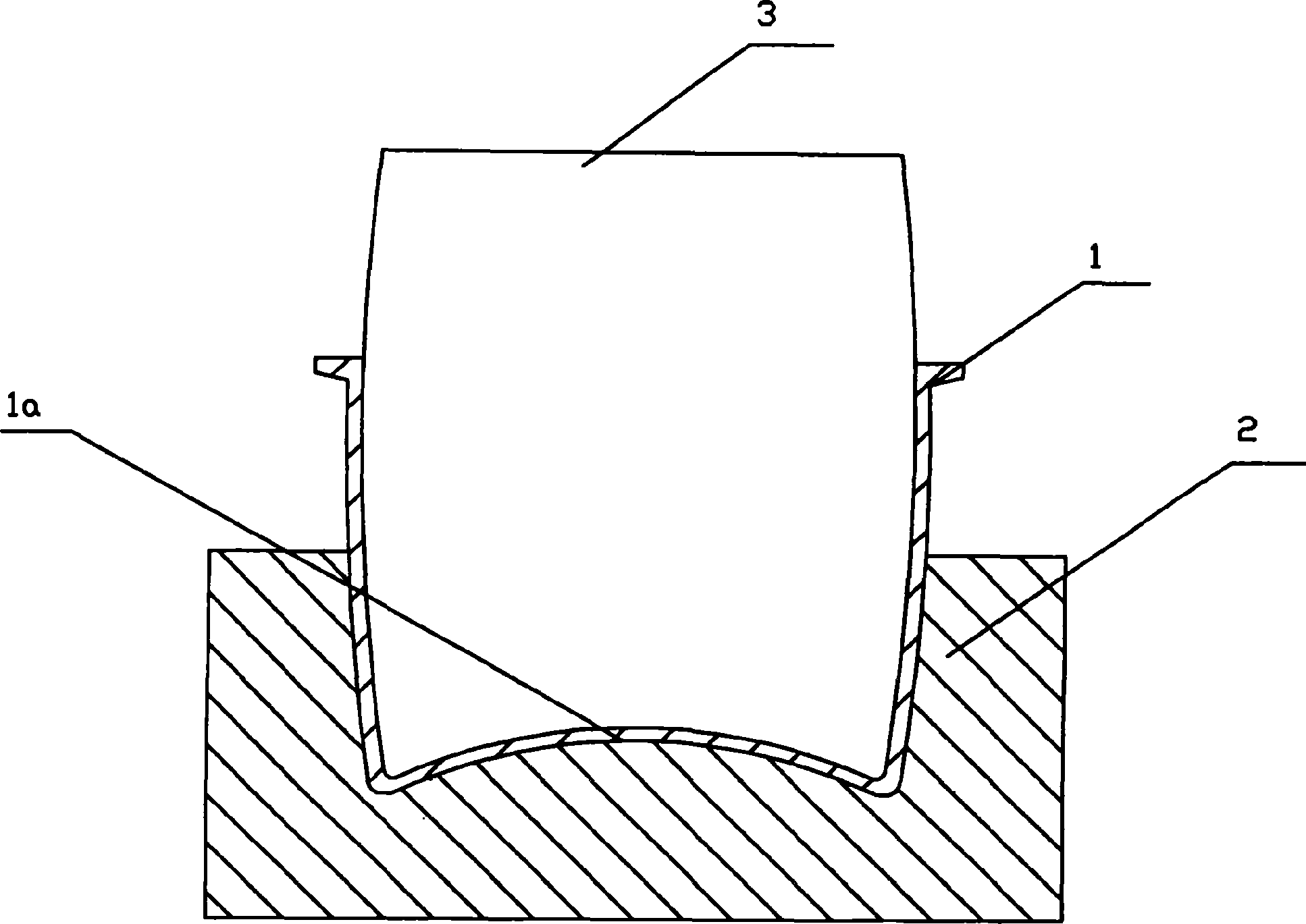

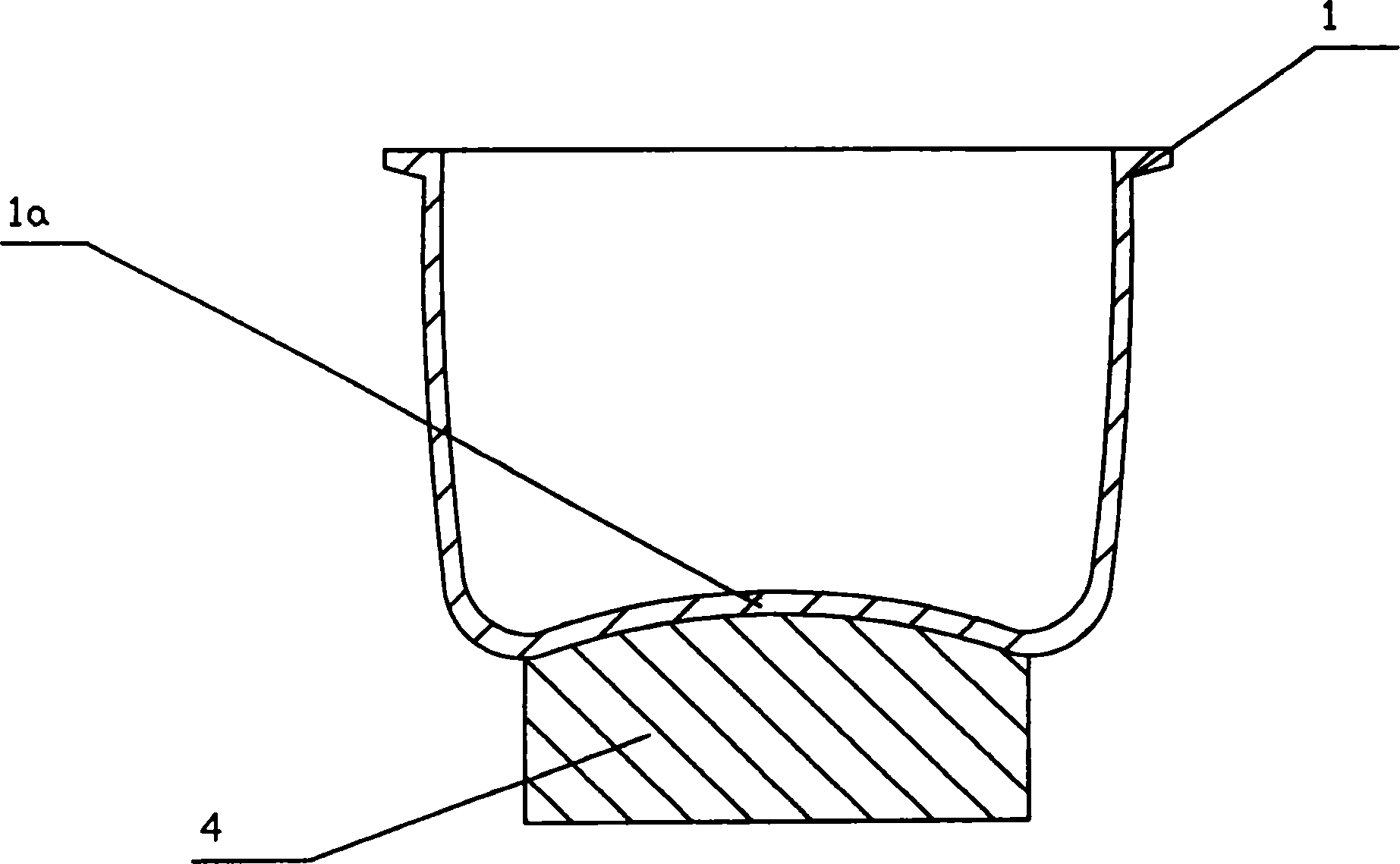

[0011] The present invention is achieved in this way, including the molding process of the clay pot body in which the bottom surface 1a of the clay pot is concave spherical, and the high-temperature firing process. Firing, the clay pot body has a certain plasticity at high temperature, and the clay pot body 1 is placed in the male and female molds 2 and 3 with fixed cavity shapes for setting (such as figure 1 Shown), in order to overcome the disordered deformation in the high temperature firing process. In order to further accurately control the external dimensions of the clay pot, a grinding process is set after the setting process, that is, the concave spherical bottom surface 1a is polished by the convex spherical emery wheel 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com