A rotary fire head device and method for sealing quartz glass tubular devices

A technology of quartz glass and rotary drive device, which is applied in glass forming, glass reshaping, burning methods, etc. It can solve problems such as bad shape, high pressure, and fried tubes, so as to improve product qualification rate and flame utilization rate High, good roundness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

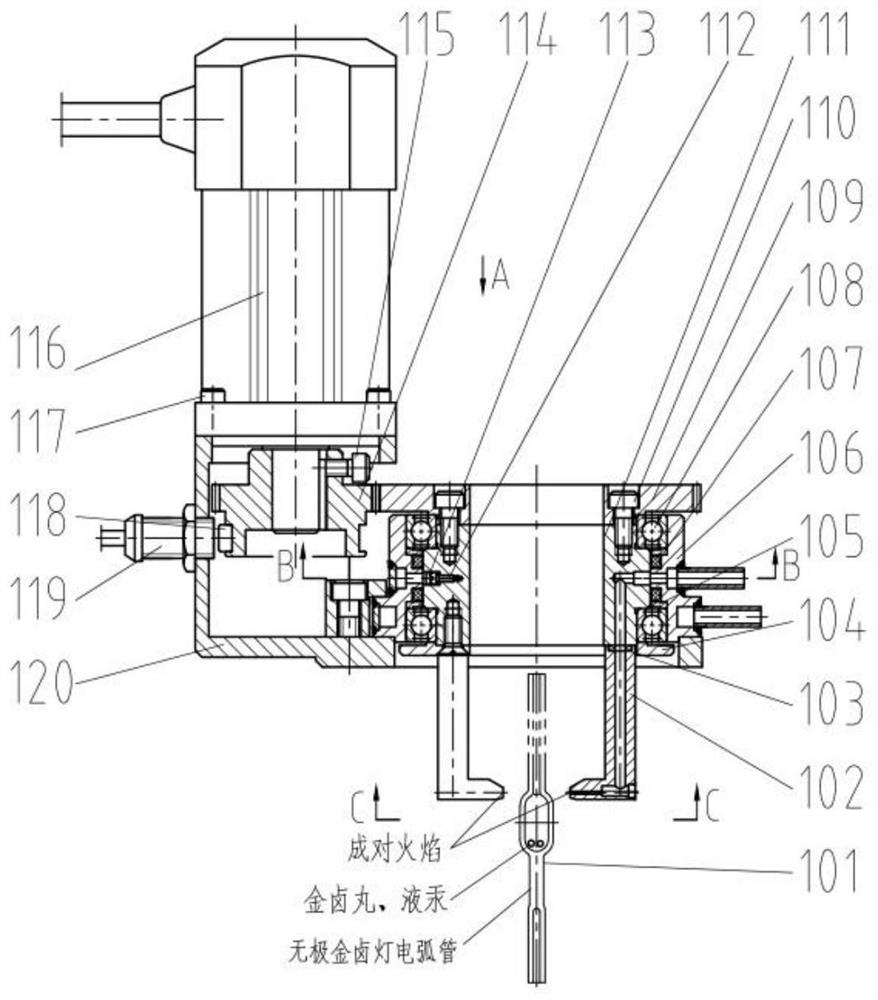

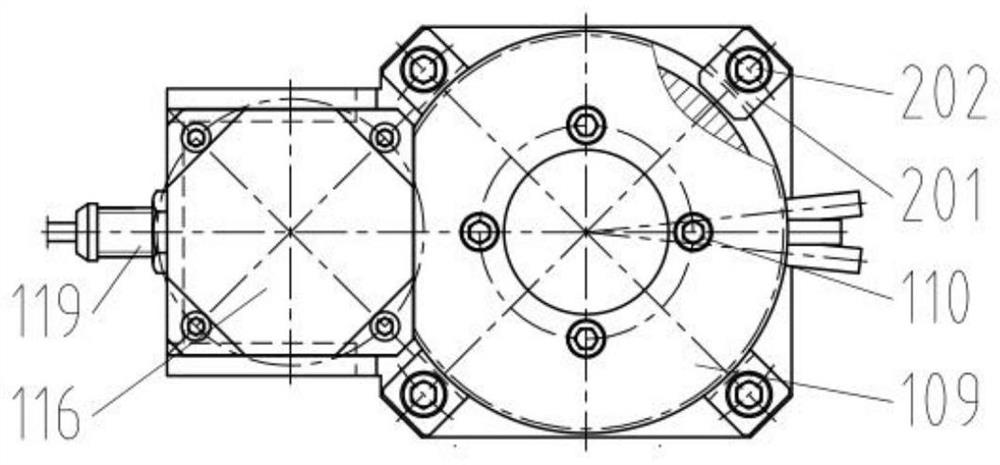

[0034] Below in conjunction with accompanying drawing, application example and device structure are described to the implementation of the present invention:

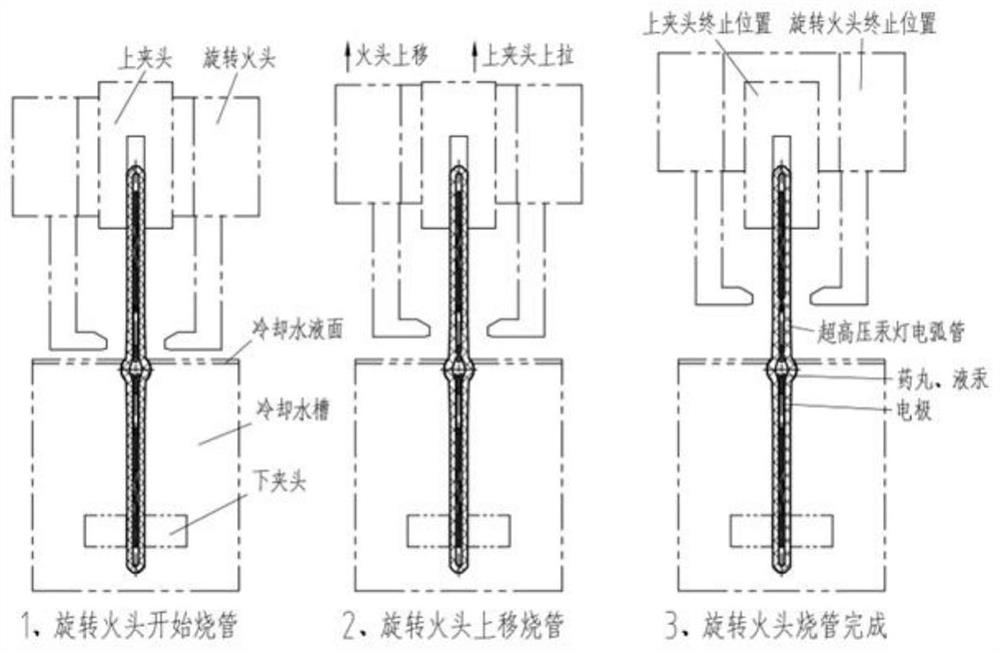

[0035] The rotary burner device of the present invention applies flames to the outside of the quartz glass tubular device that needs to be sealed, heats and melts the quartz glass material step by step, and shrinks and seals the tubular device under the action of the pressure difference between the inside and outside of the tubular device. Examples of its application are figure 1 Shown: Electrodes, pellets, and liquid mercury are installed in the arc tube of the ultra-high pressure mercury lamp that needs to be shrunk, and a vacuum is formed in the arc tube. In the water tank, the liquid level of the cooling water in the water tank just covers the bulb of the arc tube to prevent the pills and liquid mercury in the bulb from evaporating during sealing. The melted and melted quartz glass (vacuum inside the arc tube) shri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com