Landfill device for rigid solid waste landfill

A solid waste and landfill technology, which is applied in the fields of solid waste removal, landfill technology, waste collection and transfer, etc. It can solve time-consuming and labor-intensive problems, soil pollution at the burial site, and inability to place solid waste in landfill, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

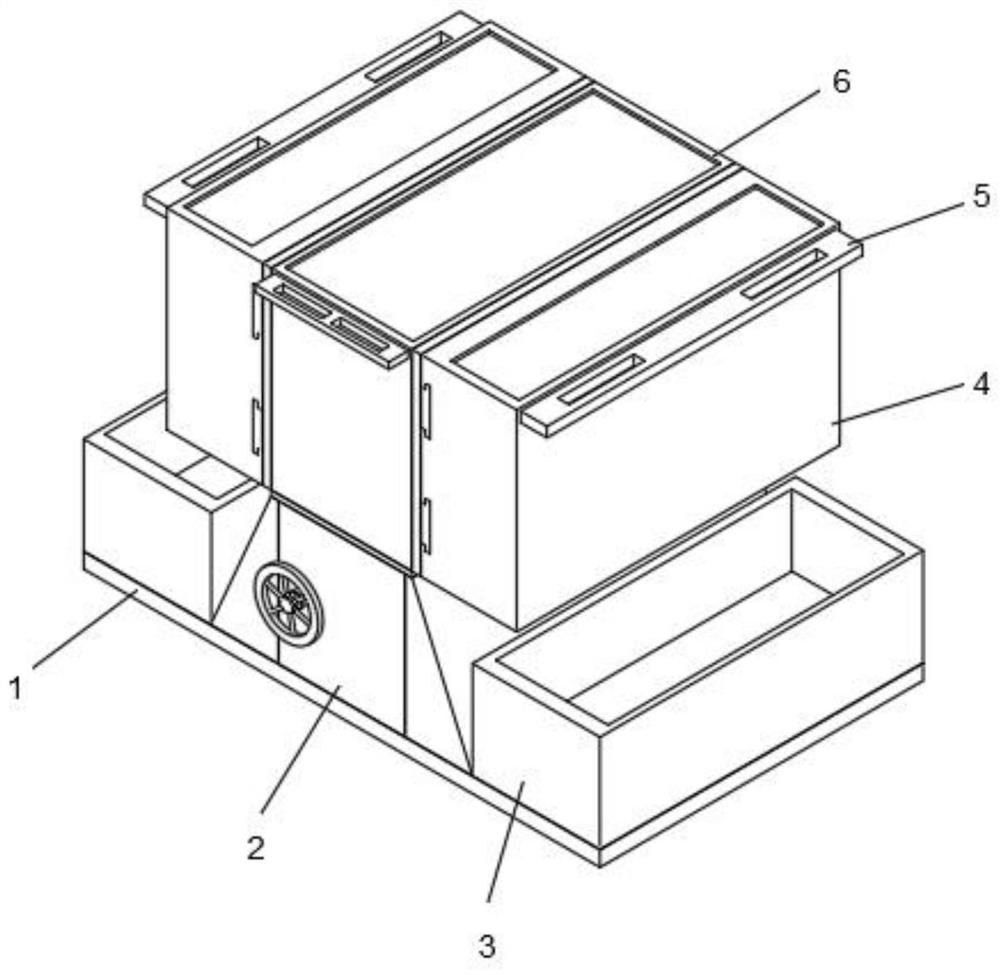

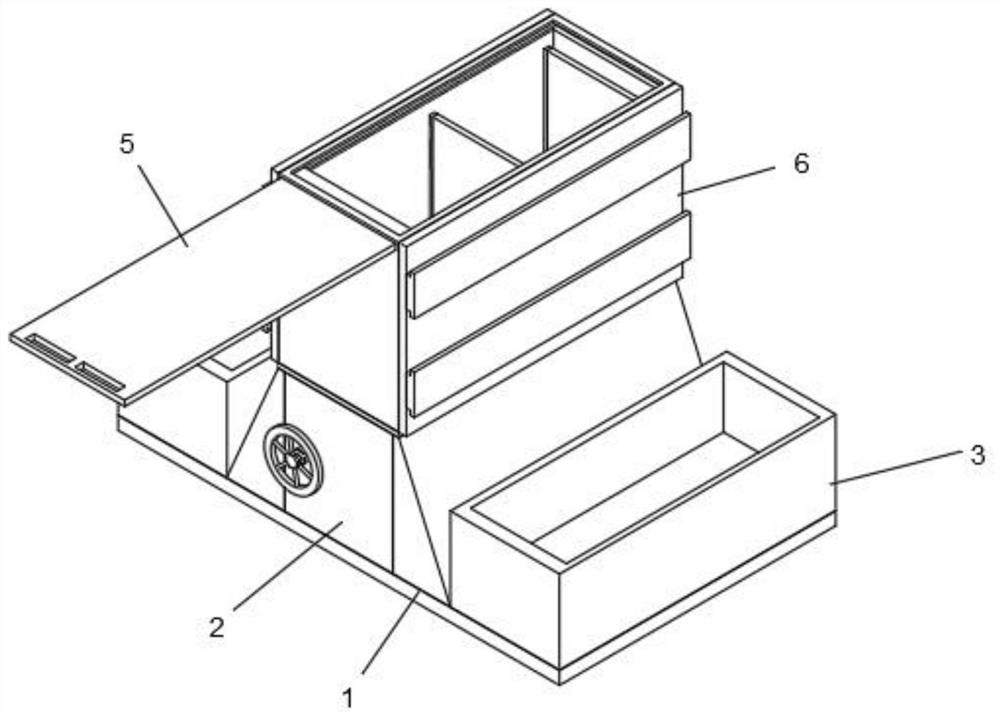

[0040] Such as Figure 1-2 , a solid waste rigid landfill landfill device, comprising a support base 1, an adjustment control device 2, an auxiliary storage frame 3, an auxiliary storage box 4, a sliding sealing plate 5 and a partition storage box 6, the adjustment control device 2 is fixedly connected to the middle part of the upper end of the support base 1, the auxiliary storage frame 3 is distributed on both sides of the adjustment control device 2, and the auxiliary storage frame 3 is fixedly connected to the upper end of the support base 1, and the partition storage box 6 is fixedly connected to the upper end of the adjustment control device 2, the auxiliary storage box 4 is slidably installed on both sides of the separated storage box 6, and the sliding sealing plate 5 is slidably installed on the upper ends of the auxiliary storage box 4 and the separated storage box 6 . The harmful solid waste stained with chemical substances can be separated and isolated by setting ...

Embodiment 2

[0042] Such as image 3 , as a further optimization scheme of the above embodiment: a solid waste rigid landfill landfill device, including a support base plate 1, an adjustment control device 2, an auxiliary storage frame 3, an auxiliary storage box 4, a sliding sealing plate 5 and a partition Place the box 6, the adjustment control device 2 is fixedly connected to the upper middle of the support base plate 1, the auxiliary storage frame 3 is distributed on both sides of the adjustment control device 2, and the auxiliary storage frame 3 is fixedly connected to the support base plate 1, the partition box 6 is fixedly connected to the upper end of the adjustment control device 2, the auxiliary storage box 4 is slidably installed on both sides of the partition box 6, and the sliding sealing plate 5 is slidably installed on the auxiliary storage box. Case 4 and the upper end of case 6 are placed separately. The adjustment control device 2 includes an adjustment control part 7, a...

Embodiment 3

[0044] Such as Figure 4-6 , as a further optimization scheme of the above embodiment: a solid waste rigid landfill landfill device, including a support base plate 1, an adjustment control device 2, an auxiliary storage frame 3, an auxiliary storage box 4, a sliding sealing plate 5 and a partition Place the box 6, the adjustment control device 2 is fixedly connected to the upper middle of the support base plate 1, the auxiliary storage frame 3 is distributed on both sides of the adjustment control device 2, and the auxiliary storage frame 3 is fixedly connected to the support base plate 1, the partition box 6 is fixedly connected to the upper end of the adjustment control device 2, the auxiliary storage box 4 is slidably installed on both sides of the partition box 6, and the sliding sealing plate 5 is slidably installed on the auxiliary storage box. Case 4 and the upper end of case 6 are placed separately. The adjustment control device 2 includes an adjustment control part 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com