Humidity and heat equipment capable of rapidly uniformizing temperature and humidity

A temperature and humidity uniform technology, applied in heating or cooling equipment, chemical instruments and methods, laboratory appliances, etc., can solve the problems of poor temperature and humidity uniformity and long time spent, and achieve good temperature and humidity uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

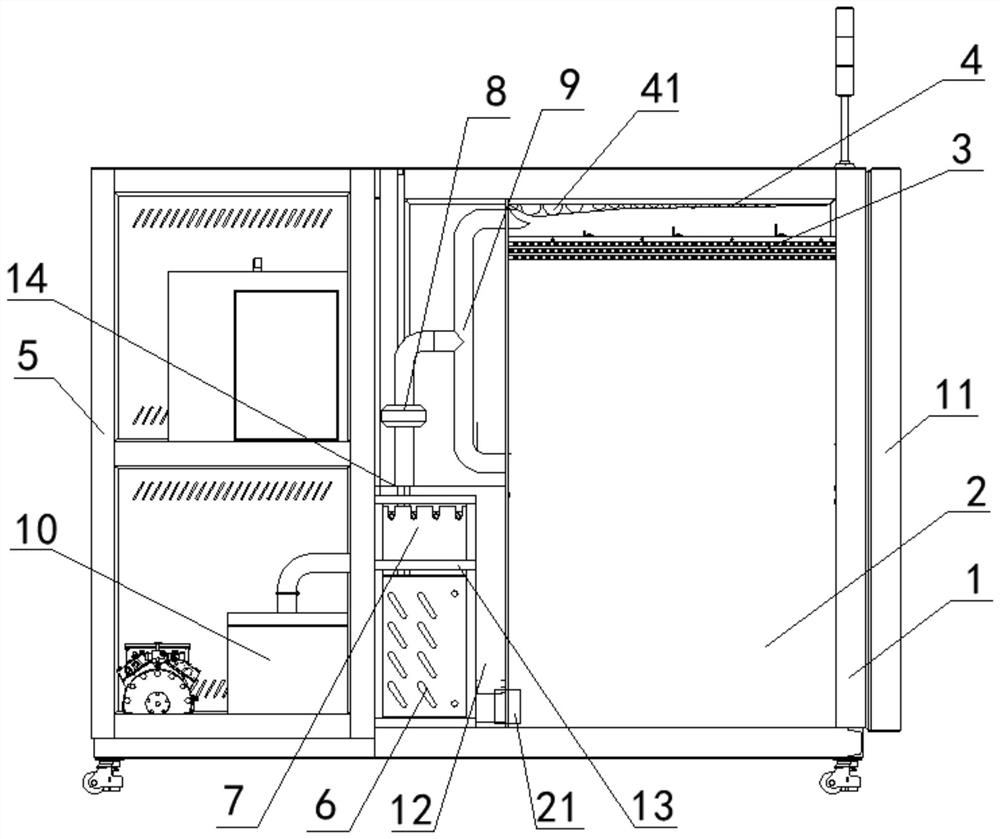

[0021] a kind of like figure 1 The damp heat equipment for fast and uniform temperature and humidity shown includes a main box body 1, an auxiliary box body 5, and an electrical system box. Wherein the main box body 1 has a sample placement chamber 2, and a shelf can be arranged in the sample placement chamber for placing samples to be tested. A front door 11 is provided at the front of the main box body 1 for opening and placing samples in the sample placement cavity 2 .

[0022] An air inlet pipe 9 is arranged on one side of the upper part of the sample placement chamber 2 , and a built-in blower 8 is arranged in the air inlet pipe 9 for sending wind into the sample placement chamber 2 . The air inlet end of the air inlet pipe 9 is connected with a humidification system 10, a refrigeration system 6, and a heating system 7 for controlling the temperature and humidity of the incoming air. The outlet end of the air inlet pipe 9 is inclined to the top surface of the sample pla...

Embodiment 2

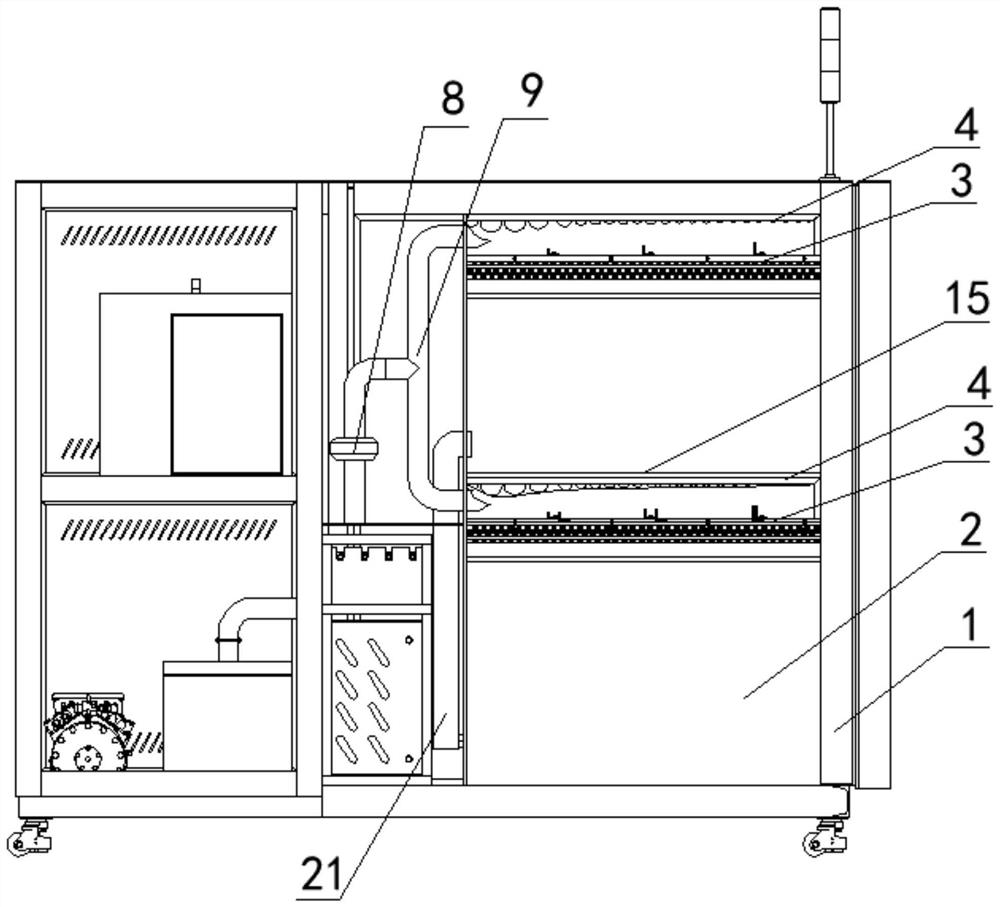

[0025] like figure 2 As shown, the rest of the structure is the same as that of Embodiment 1, and its distinguishing feature is that the sample placement chamber 2 is divided into upper and lower chambers through a middle partition 15, wherein each chamber is correspondingly provided with an air inlet and an air outlet, and each chamber The position of the chamber corresponding to the air inlet is equipped with an airflow uniform dispersion device. It can satisfy small samples and control experiments at the same time.

[0026] The humidification system 10 in the present invention is a steam generator, the refrigeration system 6 is a dehumidification evaporator, and the heating system 7 is an electric heater.

[0027] In order to further increase the dispersion effect of the airflow, there are multiple air inlet pipes 9 in the present invention and they are arranged along the width direction of the sample placement chamber 2 .

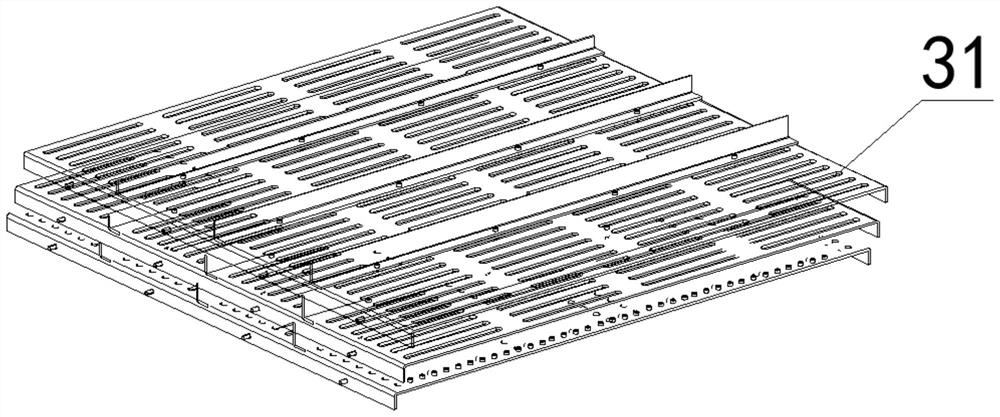

[0028] like image 3 As shown, the air guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com