Manual precise focusing and self-locking focusing mechanism

A focusing and self-locking technology, used in installation, optics, instruments, etc., can solve problems such as unstable performance, achieve high reliability and safety, improve focusing accuracy, small size and weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

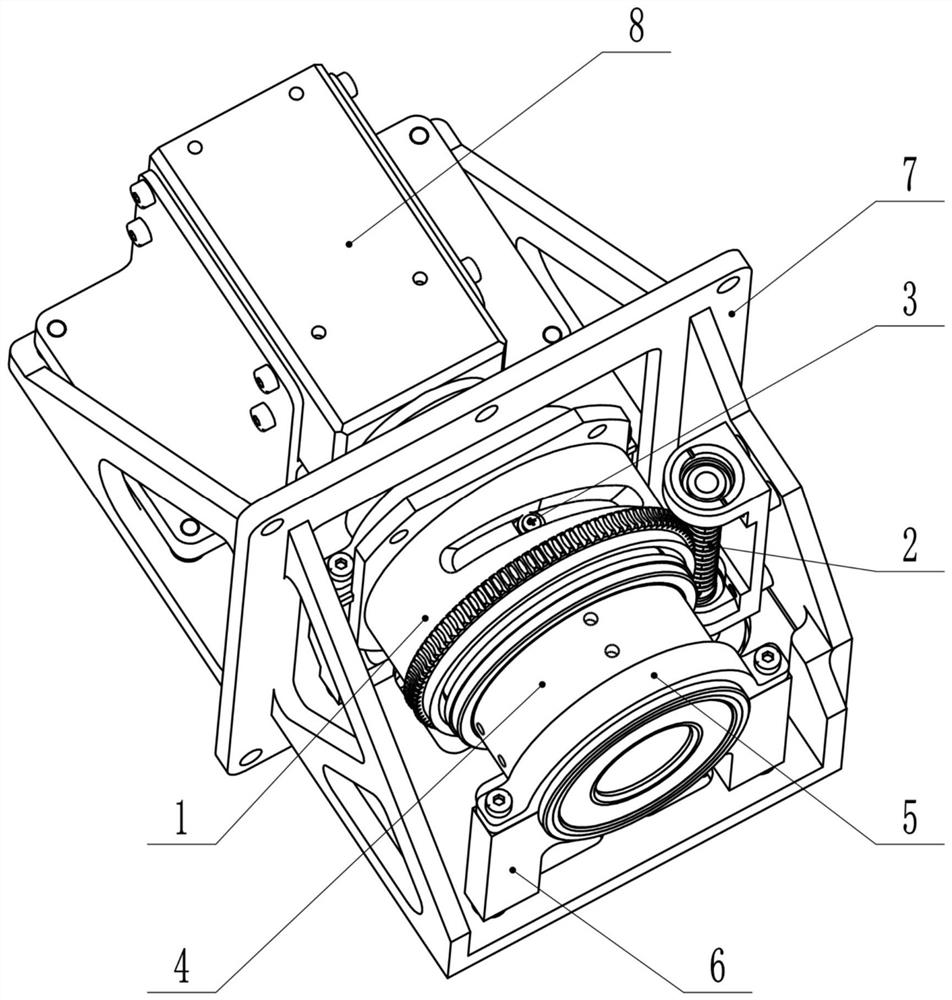

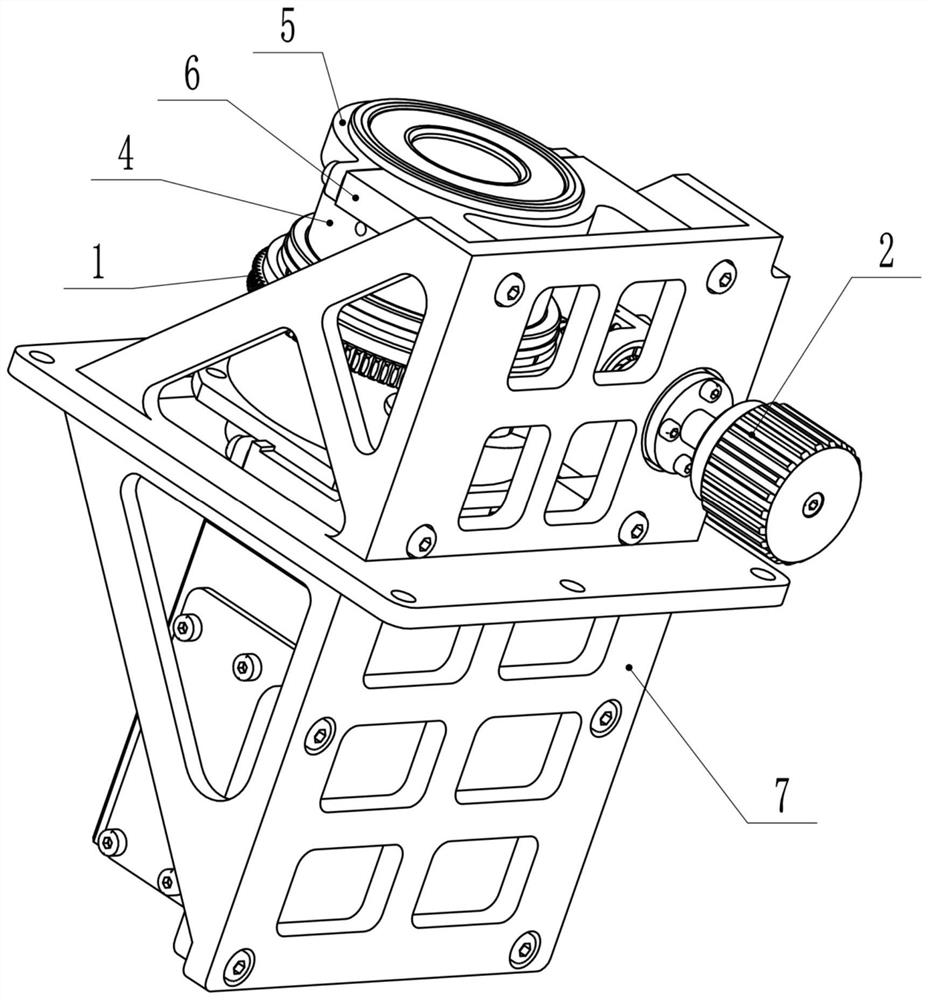

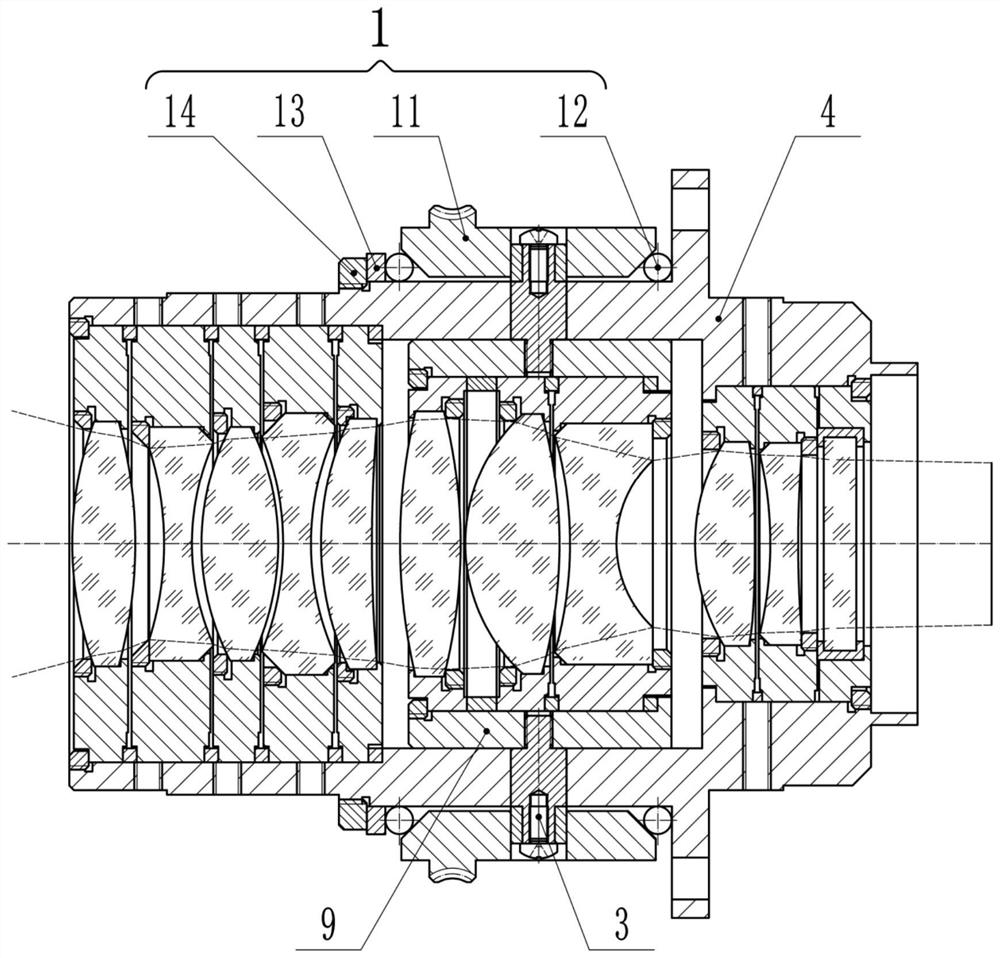

[0054] A manual precision focusing and self-locking focusing mechanism, suitable for various types of optical equipment, such as Figure 1 to Figure 7 As shown, it includes a main frame 7, a lens barrel 4, a lens, an electrical assembly 8, a cam assembly 1, a pin assembly 3 and a worm assembly 2; Frame, fixed on the left and right edges of the front and rear surfaces of the vertical frame and the four side plates fixed to the upper surface of the central bottom plate respectively; On the bottom plate, the electrical component 8 is located at the rear end of the lens. The optical signal detection surface inside the electrical component 8 is located at the focal plane of the lens after the focus adjustment is completed. The purpose of focusing is to make the optical signal detection surface always coincide with the focal plane of the lens. The installation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com