Three-tap type discharge coil differential pressure detection device and method

A discharge coil and detection device technology, which is applied in the direction of measuring devices, measuring current/voltage, measuring electrical variables, etc., can solve the problems of the secondary differential pressure value error and the inability to simulate the operating conditions of the discharge coil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

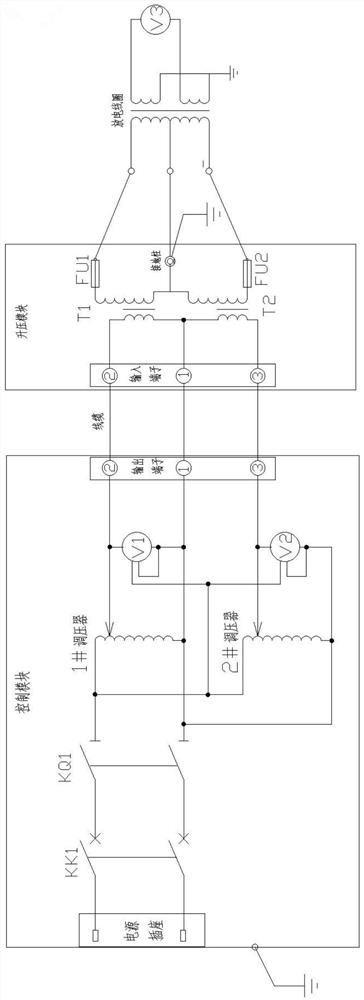

[0023] Such as figure 1 Shown is a three-tap type discharge coil differential pressure detection device, the differential pressure detection device includes a control module, a boost module and a detection module, wherein the control module is connected to an external power supply and the boost module respectively, and the The voltage input by the external power supply is adjusted to the detection voltage of the required ratio and then sent to the booster module for boosting; the booster module is connected to the primary winding of the discharge coil to be detected, and the boosted detection voltage is input for detection; The detection module includes a voltmeter V3, and the two measurement terminals of the voltmeter V3 are used to connect with the secondary winding of the discharge coil to detect the voltage difference of the secondary winding.

[0024] The control module includes a power socket, a leakage protection switch KK1, an isolating switch KQ1, a 1# voltage regulat...

Embodiment 2

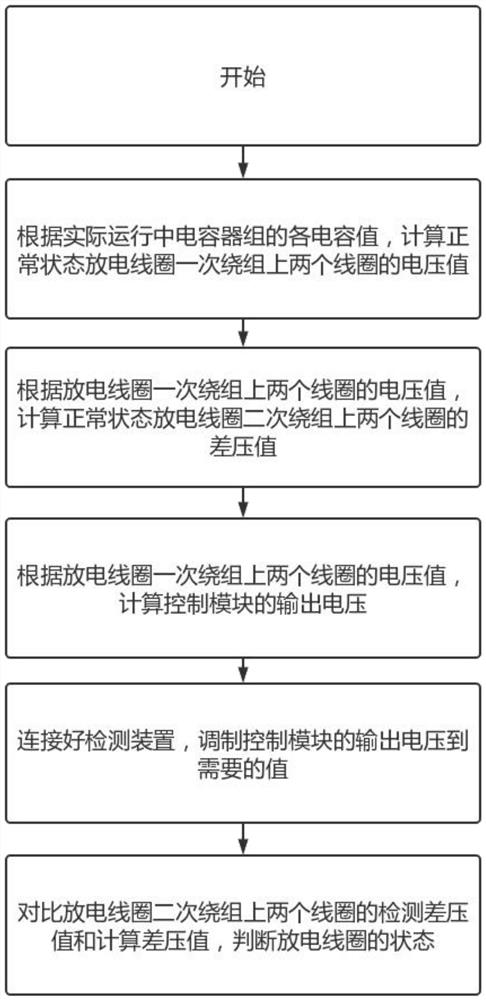

[0031] Such as figure 2 As shown, a three-tap type discharge coil differential pressure detection method, the method is applied to a three-tap type discharge coil differential pressure detection device described in the above implementation, including the following steps:

[0032] S1: According to each capacitance value of the capacitor bank in actual operation, calculate the voltage value of the two coils loaded on the primary winding of the discharge coil in parallel with it in the normal state;

[0033] S2: According to the voltage value of the two coils on the primary winding of the discharge coil, calculate the differential pressure value of the two coils on the secondary winding of the discharge coil;

[0034] S3: According to the voltage value of the two coils on the primary winding of the discharge coil and the boost ratio of the booster T1 and booster T2 in the booster module, calculate the required output voltage of the 1# voltage regulator and the 2# voltage regulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com