Joint hoop, clamping seat and underground plugging system

A collar and blockage technology, which is applied in the direction of sealing/isolation, wellbore/well parts, production fluid, etc., can solve the problems of small sealing surface, poor reliability, and poor sealing effect, so as to ensure the effect of sealing and blocking , The probability of sealing and blocking failure is reduced, and the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

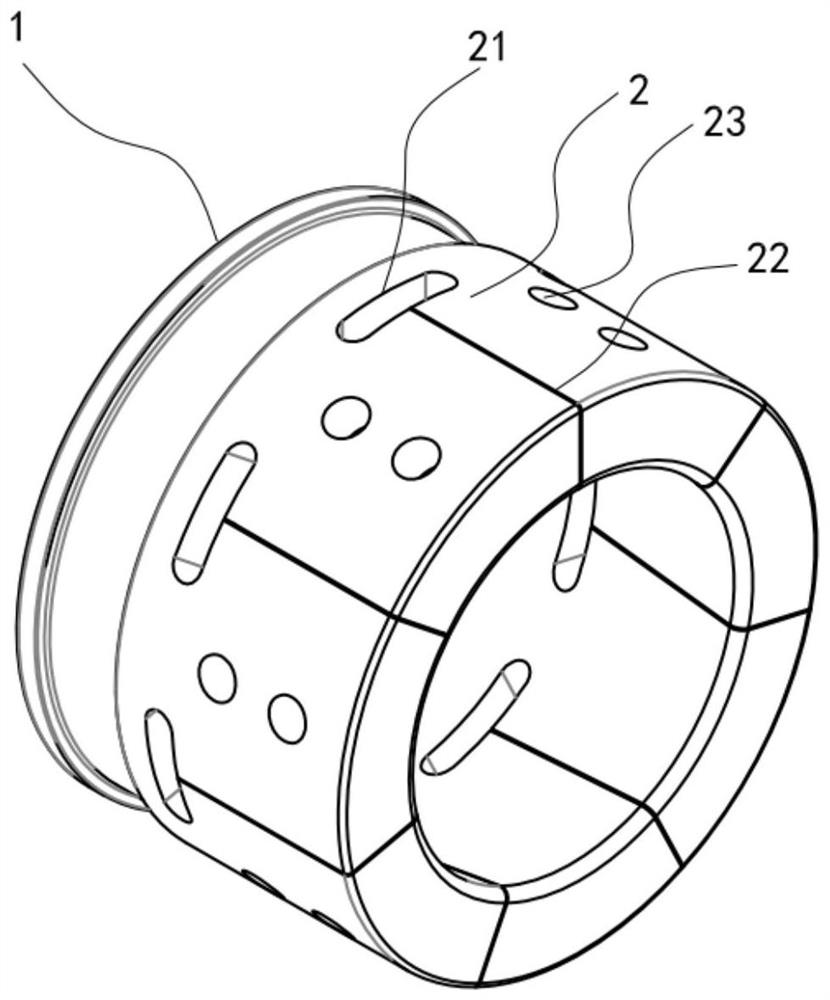

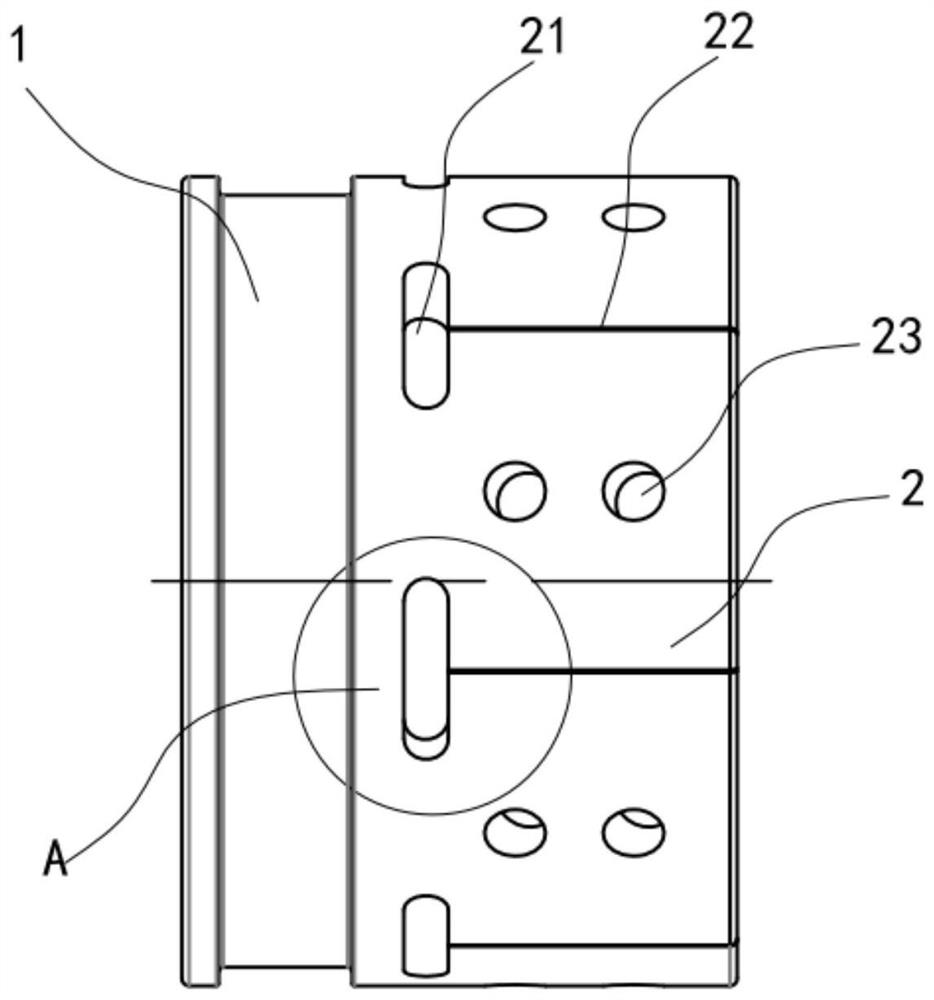

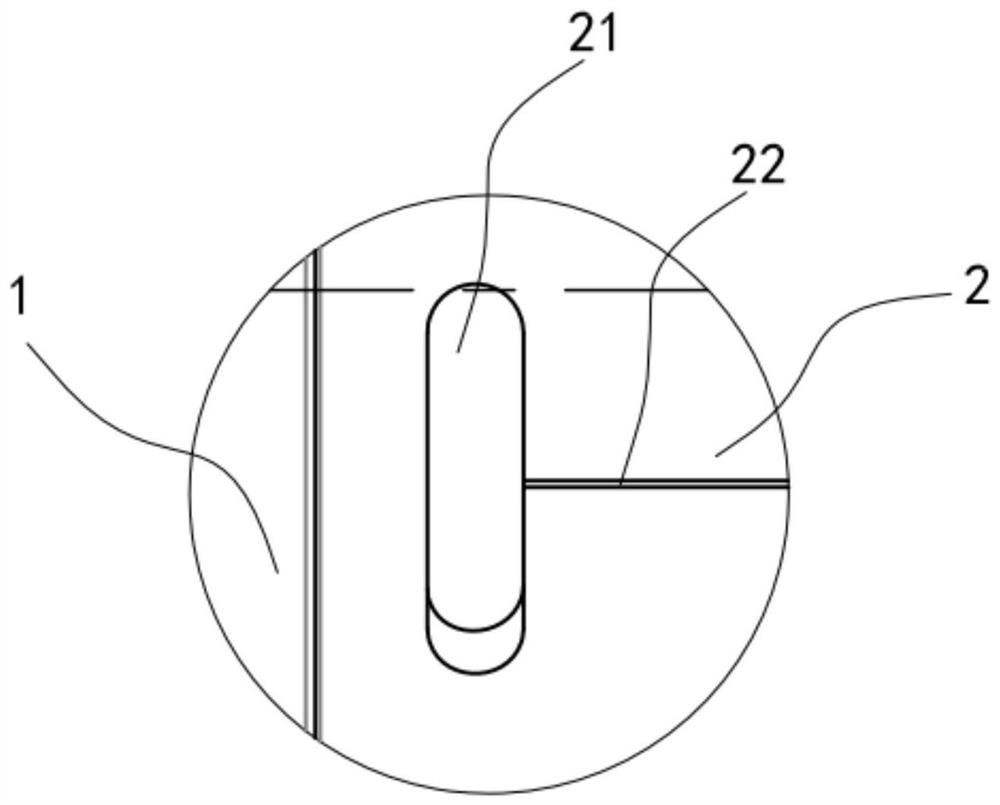

[0047] For the structural diagram of Embodiment 1 of the invention section hoop, refer to Figure 1-Figure 4 . A section hoop, the section hoop is a plastically deformed component, and an internal channel is provided in the axial direction of the section hoop, including a sealing ring and slips that are integrated in an integrated structure, wherein the outer surface of the sealing ring is deformed in the radial direction and the wellbore The inner wall is sealed, the slips are radially opened and anchored to the inner wall of the wellbore, the inner channel of the sealing ring has a tapered sealing sealing surface, and the tapered sealing sealing surface is used to contact the outer surface of the sealing body to s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com