A corrugated metal hose net sleeve compression ring locking device and method

A metal hose and locking device technology, applied in auxiliary devices, metal processing equipment, auxiliary welding equipment, etc., can solve the problems of affecting the effect of the head, the non-folding of the mesh sleeve, poor universality of the rigid mold, etc., and improve the deformation amount. Insufficient, difficult to improve welding, easy welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

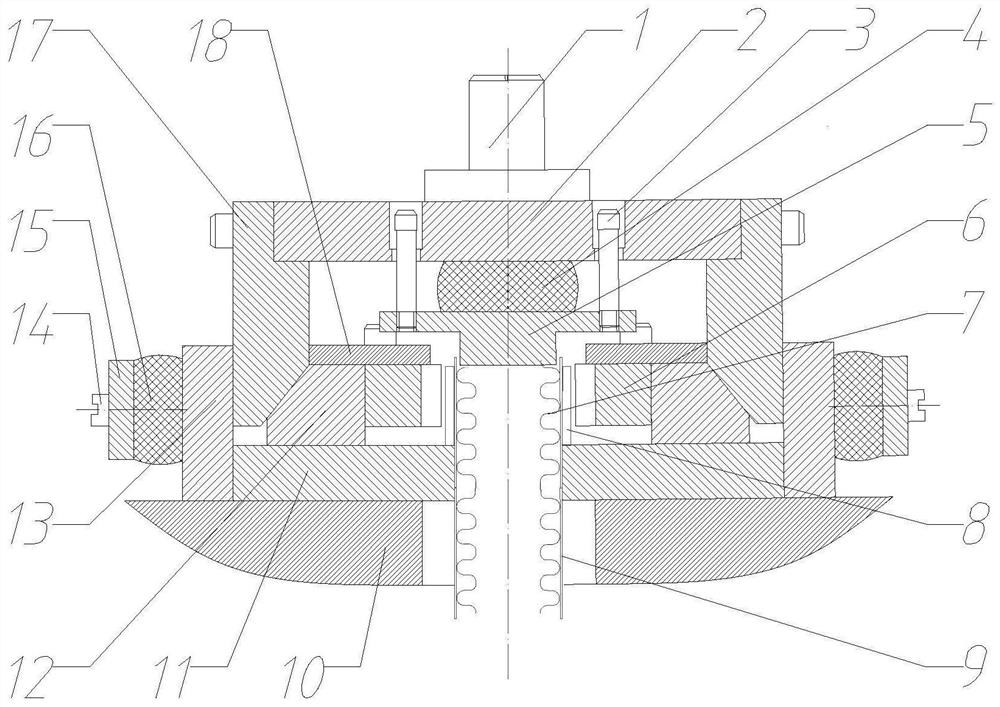

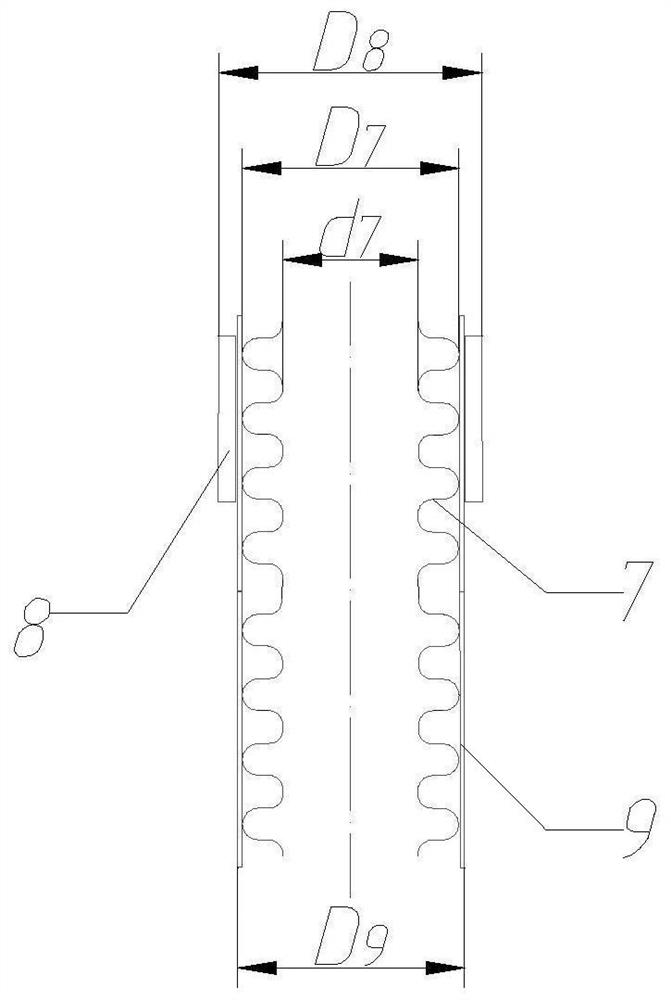

[0036] refer to figure 1, a corrugated metal hose net sleeve compression ring locking device, including a driving part and a driven part;

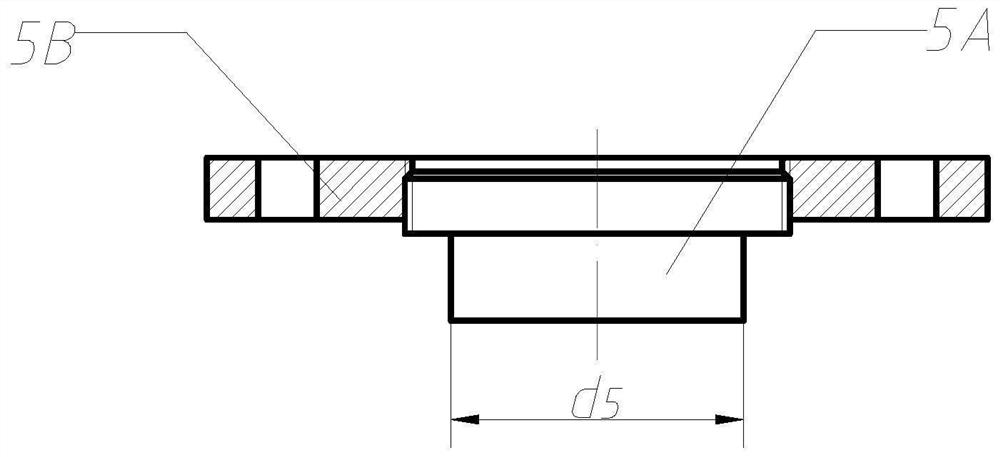

[0037] The active part includes a mold handle 1, an upper mold frame 2, a first guide column 3, a first elastic element 4, an upper mold frame 5 and a wedge 17; It is connected with the upper end of the first guide post 3, and the lower end of the first guide post 3 is fixedly connected with the upper mold 5. The first guide post 3 can move up and down in the guide post installation hole of the upper mold frame 2, but is limited by the upper end of the first guide post 3. Constrained with the upper mold 5, the first guide post 3 does not break away from the guide post installation hole; the first elastic element 4 is arranged between the upper mold frame 2 and the upper mold 5, and the first elastic element 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com