Puncture type suction head and full-automatic suction feeding device for chemical powder and particle raw materials

The technology of suction head and suction tube is applied in the field of puncture suction head and automatic suction and feeding device for chemical powder raw materials, which can solve the problems of cumbersome unpacking and feeding process, easy mixing of suction materials with foreign objects, etc. The effect of saving manpower, reducing production costs and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

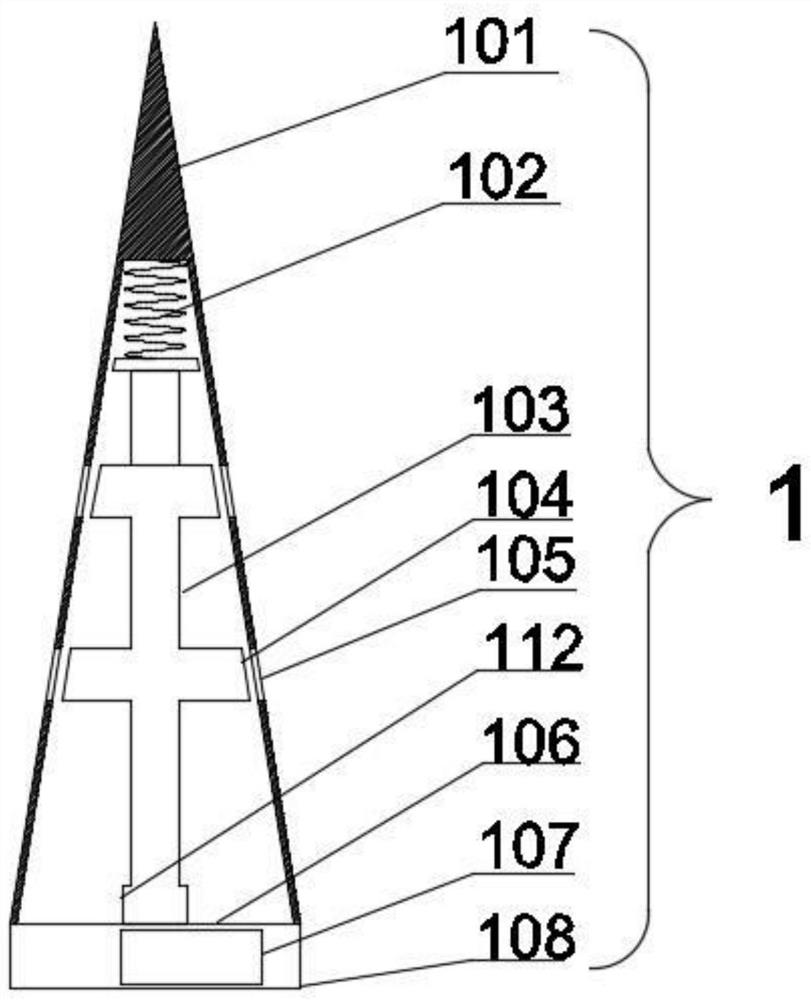

[0039] Such as figure 1As shown, the present invention is a piercing suction head, which is used for piercing and suctioning bagged chemical powder raw materials. The suction head 1 comprises a puncture shell 101 and a suction tube 103 arranged inside the puncture shell 101; the puncture shell 101 is conical, and the top of the puncture shell 101 is a conical tip, which is used as a puncture part for puncturing the material bag 3, and the puncture The inside of the piercing part is a solid structure to enhance the strength of the piercing part and avoid being squeezed and deformed by the material during the piercing process; the side wall of the piercing shell 101 is provided with a feed port 105, and the feed port 105 is along the height of the piercing shell 101 side wall The direction is provided with multiple rows, and each row of feeding ports 105 is distributed around the puncture shell 101 at intervals; the suction tube 103 is arranged in the cavity part inside the punc...

Embodiment 2

[0042] Such as figure 1 As shown, on the basis of Embodiment 1, the upper end of the suction pipe 103 is connected to the solid structure in the puncture shell 101 through the spring 102, the lower end of the suction pipe 103 is connected to the reciprocating mechanism 107, and the suction of the suction pipe 103 There is a gap between the port 104 and the corresponding feed port 105, and the radial direction of the opening at the suction port 104 is parallel to the side wall of the puncture shell 101; Figure 6 As shown, the suction tube 103 is axially displaced relative to the puncture housing 101 under the action of the reciprocating mechanism 107, and returns to the initial position under the joint action of the spring 102 and the suction tube 103's own gravity. When the suction pipe 103 moved up, the suction port 104 and the feed port 105 were misplaced, and when the position of the suction pipe 103 got back to the initial position, the suction port 104 and the feed port ...

Embodiment 3

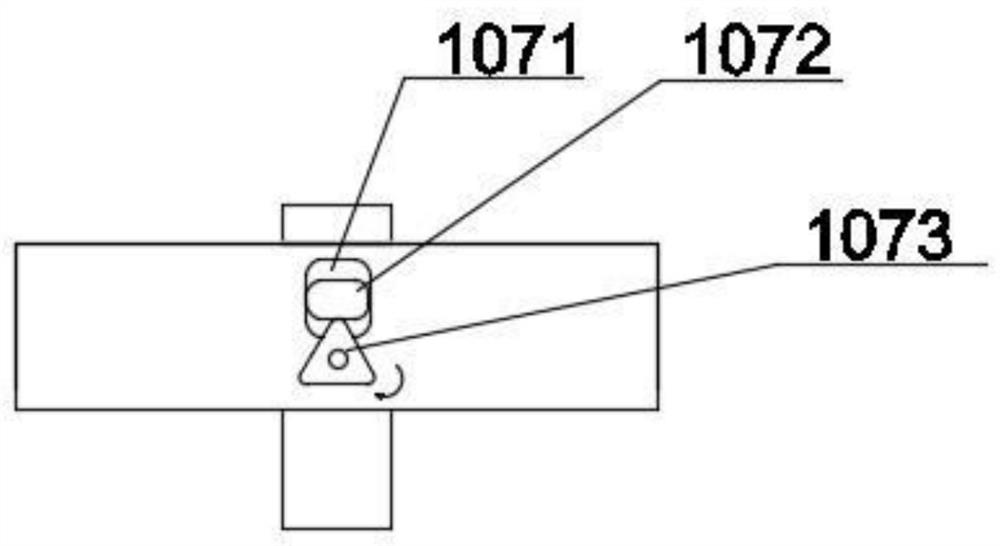

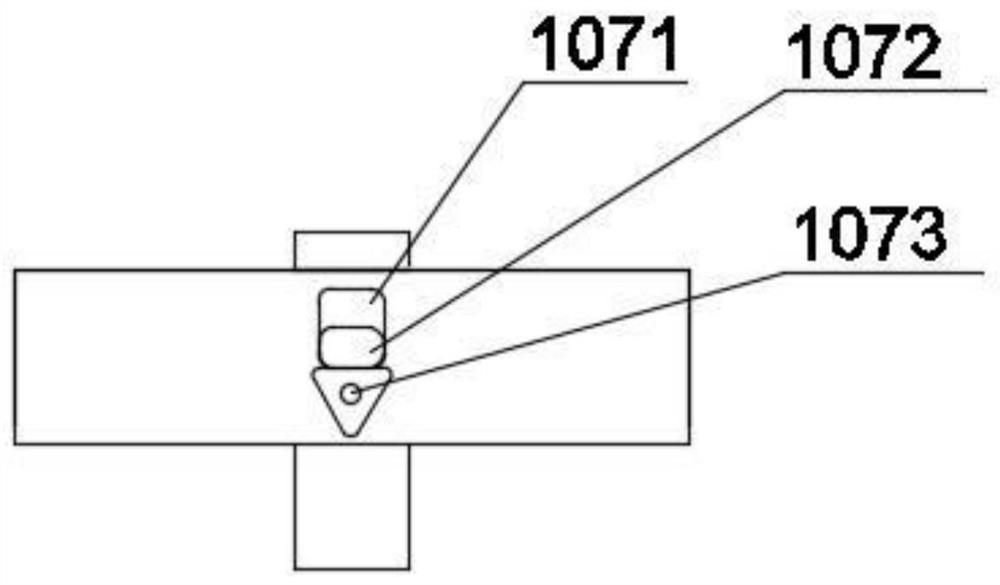

[0047] Such as Figure 4 , Figure 5 As shown, the main structure of the third embodiment is the same as that of the second embodiment, except that in the third embodiment, a da Vinci hammer is used as the driving component to drive the suction tube 103 to reciprocate in the puncture shell 101 . The Da Vinci hammer includes a hammer head and a driving motor (not shown in the figure), and the hammer head of the Da Vinci hammer is an eccentric cam 1074 . The driving motor drives the eccentric cam 1074 to rotate. When the angle of the eccentric cam 1074 rotates to the top, the position of the sliding rod 1071 is pushed to the highest position. At this time, the spring 102 on the upper part of the suction pipe 103 is compressed, and the feeding port 105 and the suction The port 104 is dislocated; the eccentric cam 1074 continues to rotate so that the slide bar 1071 loses support instantly, and the slide bar 1071 falls rapidly under the joint action of gravity and the spring 102, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com