Multi-channel full-automatic feeding system for chemical production line

A production line and multi-channel technology, which is applied in the directions of unpacking of objects, conveying bulk materials, loading/unloading, etc., can solve problems such as danger, high labor intensity, and waste of materials, so as to improve operational safety, improve work efficiency, and avoid secondary accidents. The effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

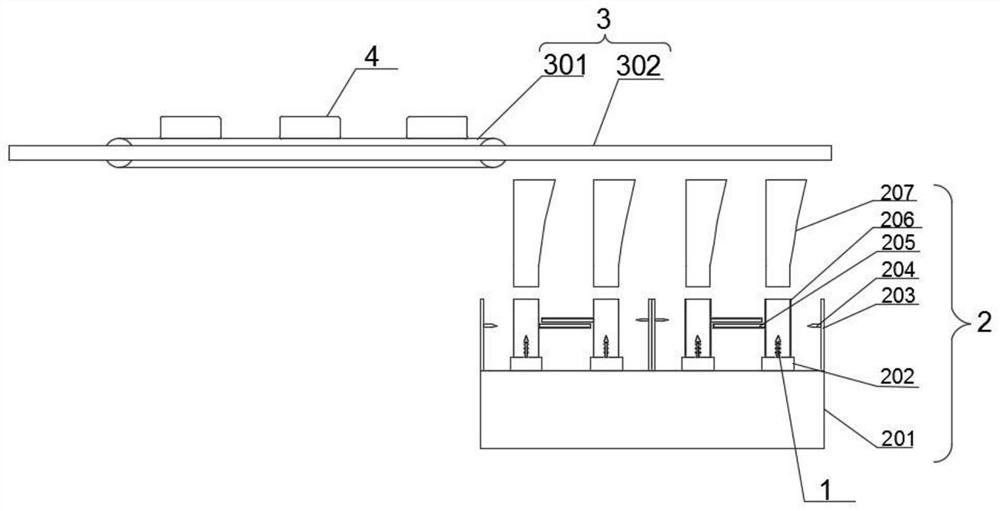

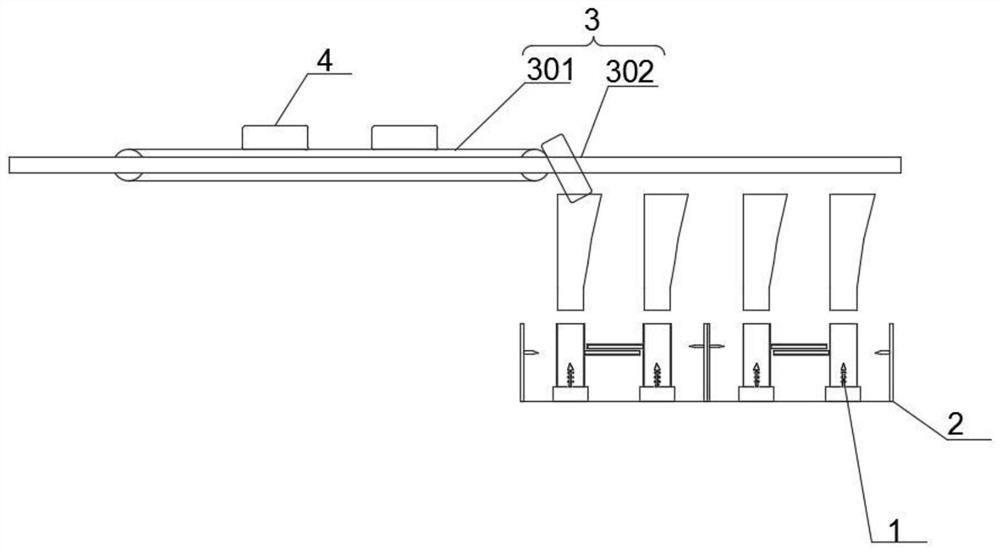

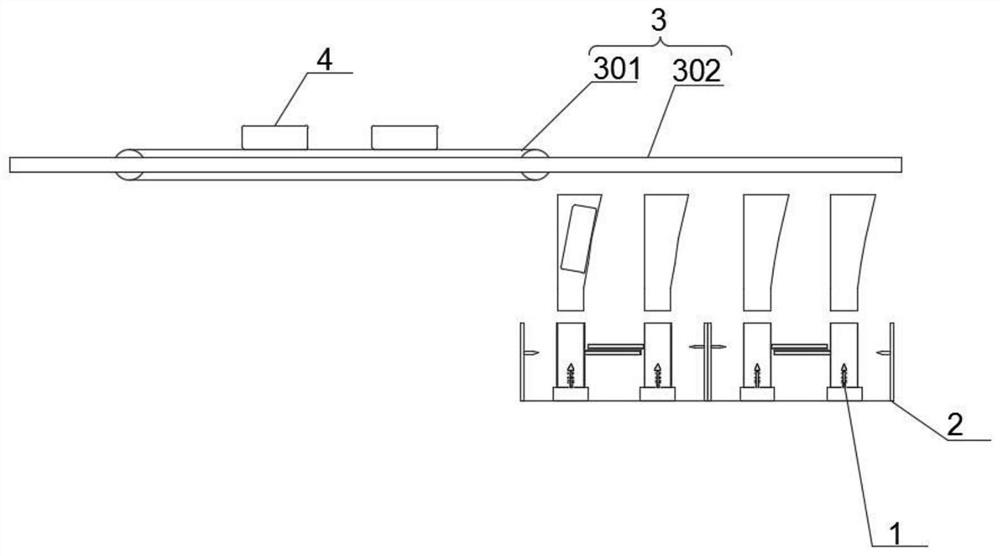

[0027] The multi-channel automatic feeding system for chemical production lines of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0028] Such as Figure 1 to Figure 7 As shown, the present invention is a multi-channel automatic feeding system for a chemical production line, including a material bag conveying mechanism 3 , a material bag carrying mechanism 2 and a material suction mechanism 1 .

[0029] The material bag conveying mechanism 3 is used to transport the material bags 4 waiting to be fed one by one to the top of the set loading station on the material bag carrying mechanism 2, and the material bags 4 can fall down by themselves under the action of gravity. The material bag carrying mechanism 2 is used to accept the falling material bag 4. In order to realize multi-channel automatic feeding, the material bag carrying mechanism 2 is provided with a plurality of carrying stations, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com