Lifting vehicle

A lifting device and lifting component technology, which is applied in the field of lifting vehicles, can solve the problems of hurting people, affecting normal excavation, and narrow space in underground roadways, so as to facilitate operations, improve production efficiency, and reduce labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041]Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

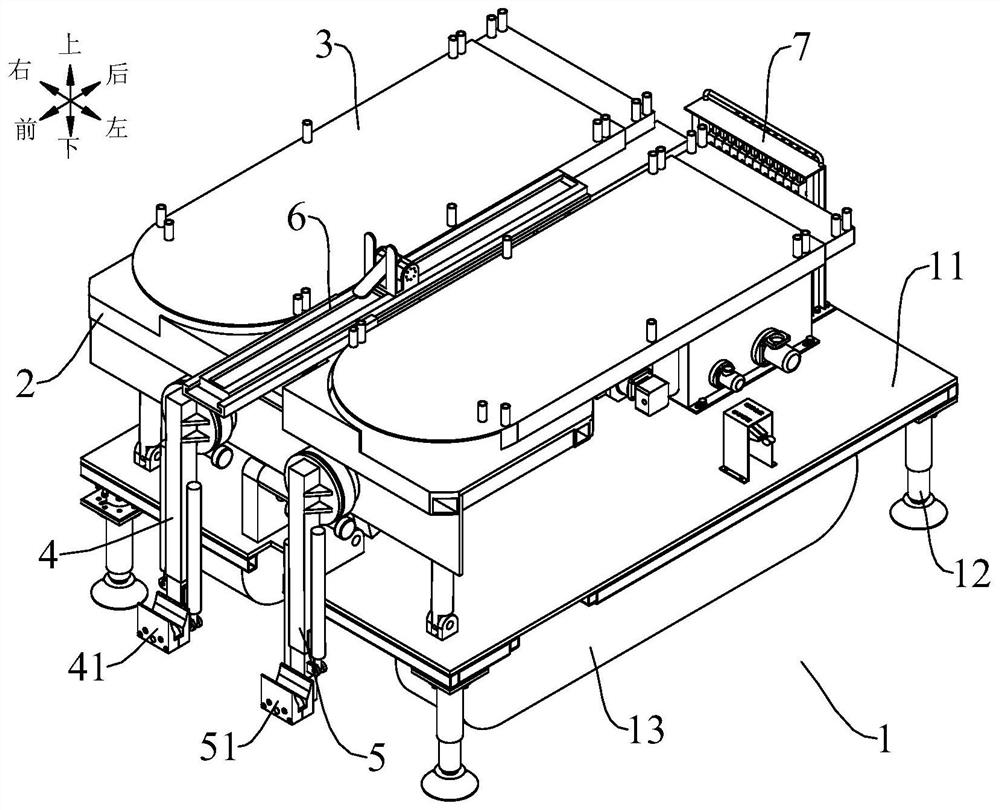

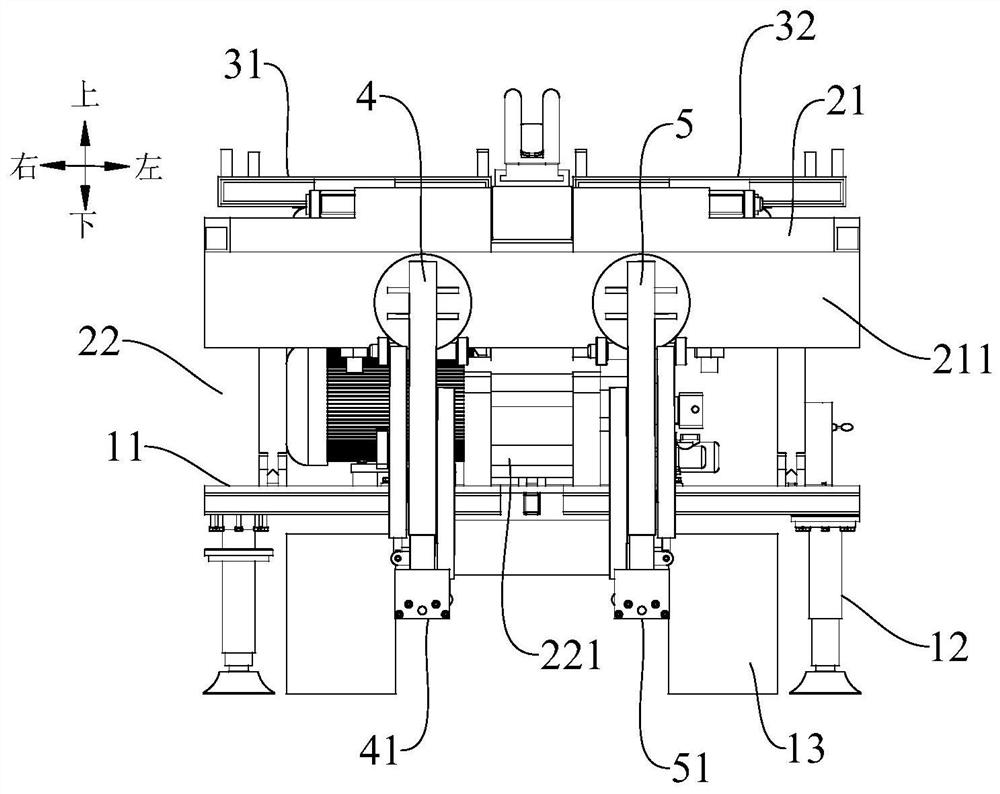

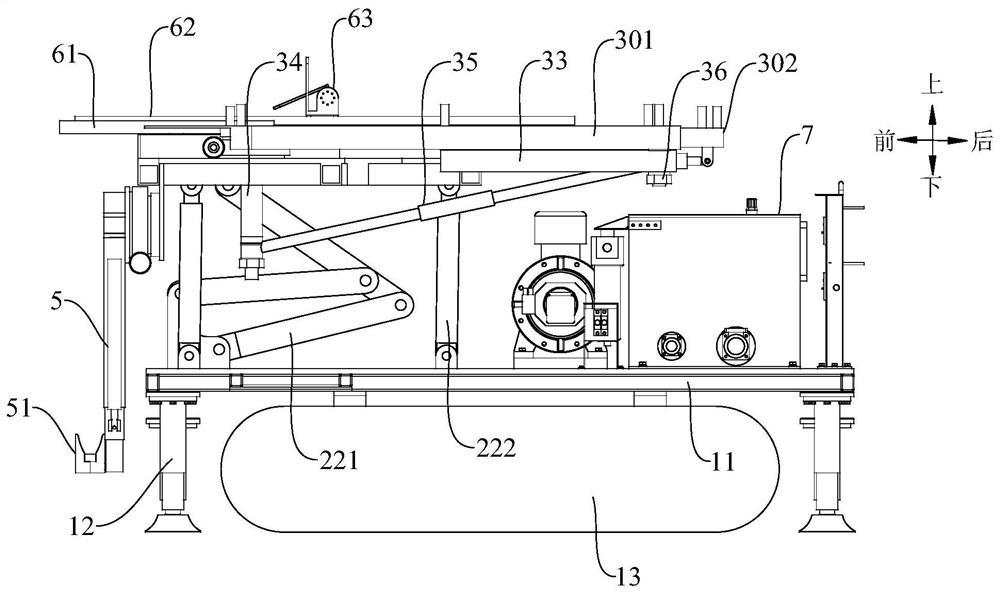

[0042] Such as Figure 1 to Figure 15 As shown, the lifting vehicle according to the embodiment of the present invention includes a traveling device 1 , a lifting device 2 , an operating platform 3 , a first arm 4 , a second arm 5 and a limiting device 6 .

[0043] The running device 1 can be a crawler wheel 13, or a tire running device 1, through which the self-propelling of the lift car can be realized, thereby facilitating the movement of the lift car position. The top of the running gear 1 is provided with a first platform 11, such as figure 1 As shown, the first platform 11 may be a rectangular platform, and the first platform 11 is mainly used for bearing....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com