Recoverable anchorage device

A technology of anchorage and body, applied in the field of anchorage, can solve the problems such as inconvenient recovery of steel strands, and achieve the effect of simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

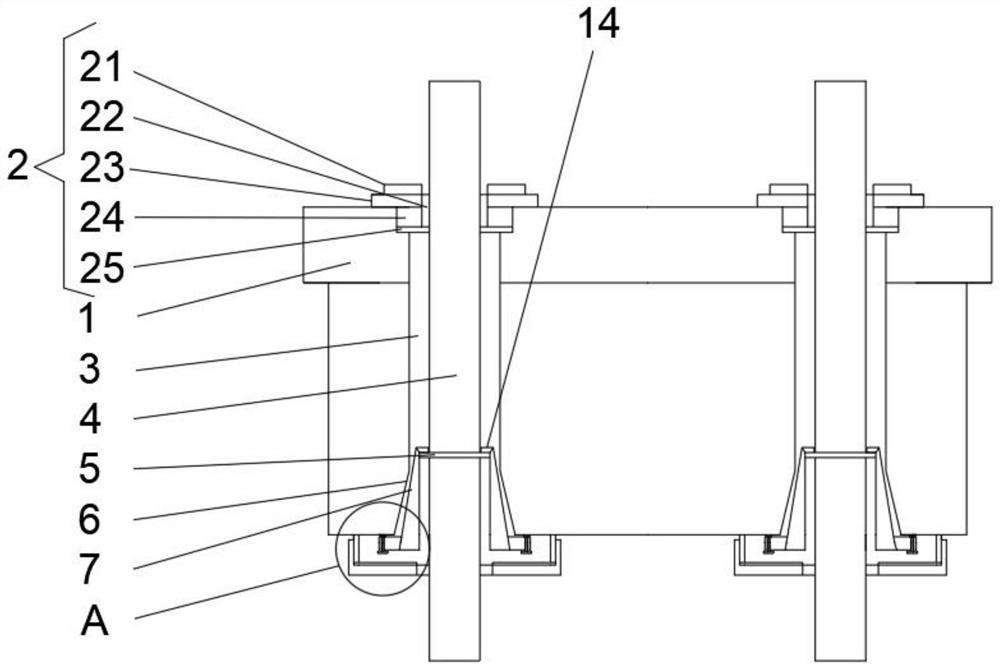

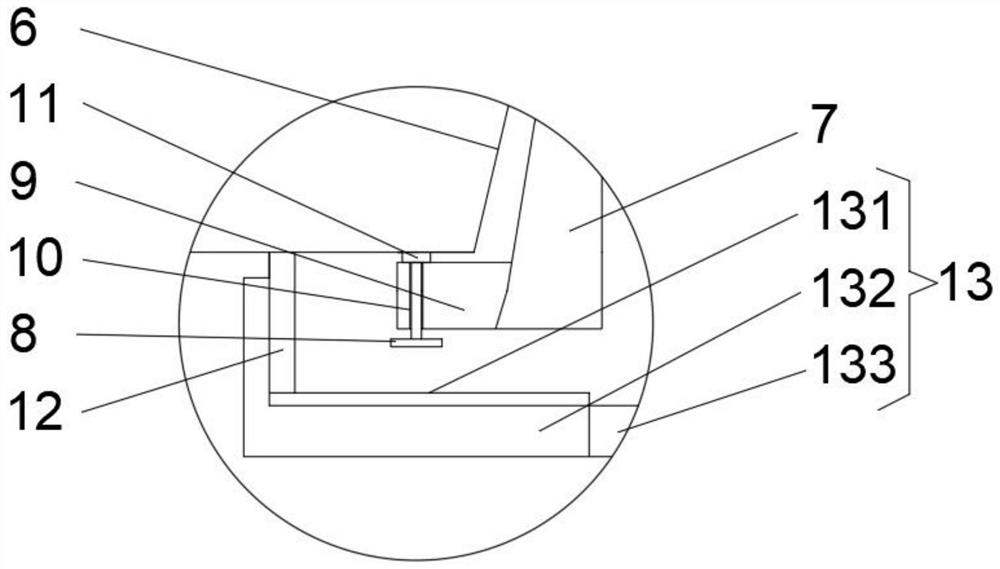

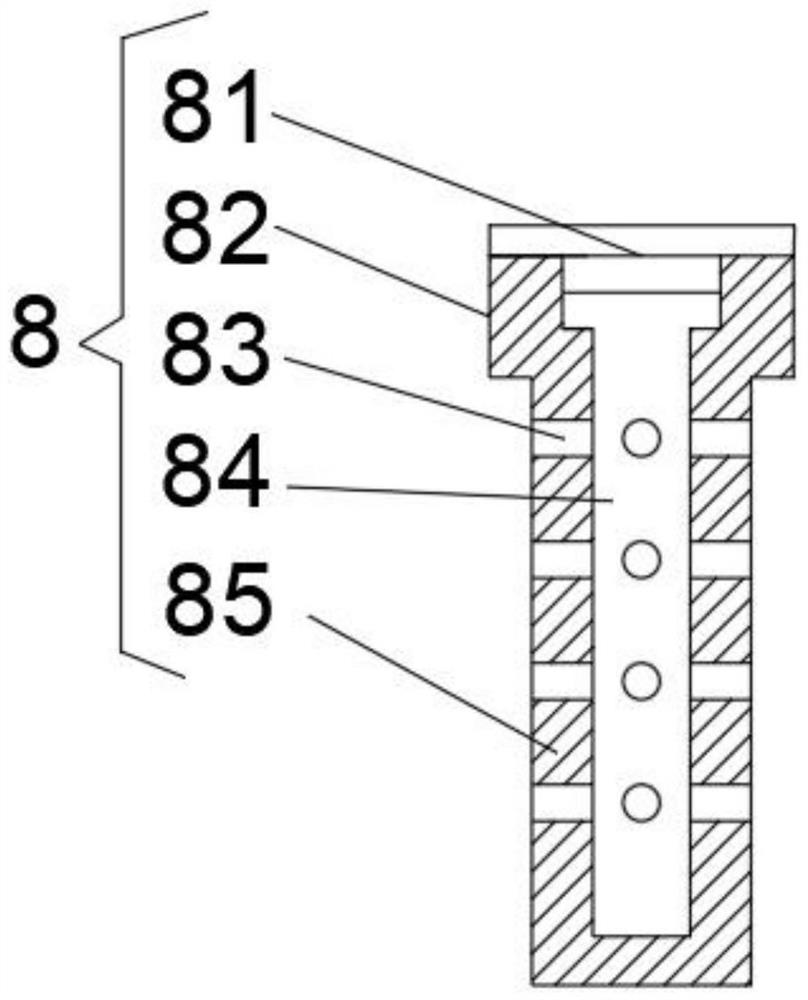

[0026] Such as Figure 1-3 As shown, a recyclable anchor described in this embodiment includes an anchor body 1, and the upper end of the anchor body 1 is uniformly provided with a vertical hole 3 passing through the upper and lower ends, and the vertical hole 3 is inserted with a steel strand 4 from the lower end. , the upper end of the vertical hole 3 is screwed with the upper sealing structure 2, the lower end of the vertical hole 3 is provided with a tapered hole 6, and the tapered hole 6 is inserted with a tapered cylinder 7, and the tapered cylinder 7 is composed of two semi-conical cylinders , the upper end of the conical cylinder 7 is provided with an annular stopper 17, the steel strand 4 is provided with a snap ring 5 at the lower end of the annular stopper, and the lower end of the conical cylinder 7 protrudes from the bottom side of the tapered hole 6;

[0027] The outside of the lower end of the tapered cylinder 7 is equipped with an annular baffle 9, and the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com