Recyclable PET (polyethylene glycol terephthalate) release material

A release material and release agent technology, applied in the direction of film/sheet release liner, etc., can solve the problems of environmental pollution, difficulty in recycling release materials, etc. hard to separate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

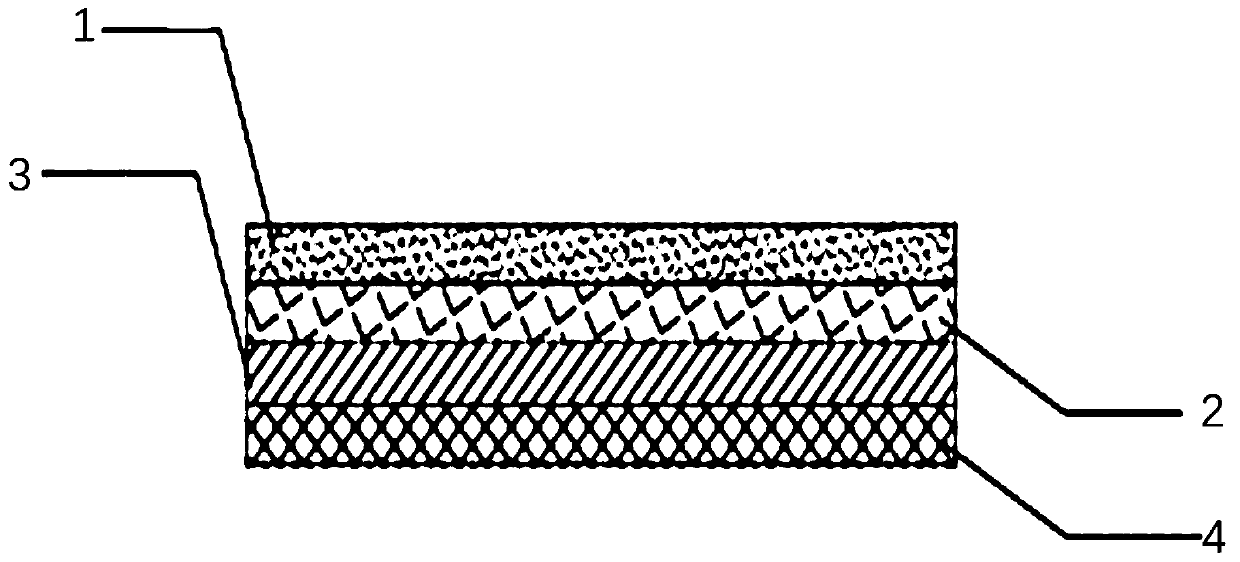

[0029] A recyclable PET release material, such as figure 1 As shown, from top to bottom are the release agent coating 1, the low-density material layer 2, the special adhesive coating 3, and the PET layer 4; the release agent coating uses silicone oil, and the low-density material layer adopts a density of 0.95g / cm 3 , LDPE material with a thickness of 16μm, the special adhesive coating adopts a washable adhesive with a density of 0.96g / cm3, and the PET layer adopts a density of 1.4g / cm3 3 , PET material with a thickness of 50 μm.

[0030] The release agent coating 1 has the function of anti-adhesive isolation.

[0031] The low-density material layer 2 has the effect of separating the release agent coating 1 from the PET layer;

[0032] The special adhesive coating 3 has high bonding strength, and it is easy to fall off from the surface of the PET layer when washing with alkaline water or warm water, and will not remain on the surface of the PET layer;

[0033] The PET la...

Embodiment 2

[0037] A recyclable PET release material, such as figure 1 As shown, from top to bottom are the release agent coating 1, the low-density material layer 2, the special adhesive coating 3, and the PET layer 4; the release agent coating uses silicone oil, and the low-density material layer adopts a density of 0.91g / cm 3 , PE material with a thickness of 10μm, and a special adhesive coating with a density of 0.9g / cm 3 Heat-shrinkable LDPE material, PET layer with a density of 1.2g / cm 3 , PET material with a thickness of 120 μm.

[0038] The release agent coating 1 has the function of anti-adhesive isolation.

[0039] The low-density material layer 2 has the effect of separating the release agent coating 1 from the PET layer;

[0040] The special adhesive coating 3 has high bonding strength, and it is easy to fall off from the surface of the PET layer when washing with alkaline water or warm water, and will not remain on the surface of the PET layer;

[0041] The PET layer 4 ...

Embodiment 3

[0043] A recyclable PET release material, such as figure 1 As shown, from top to bottom are the release agent coating 1, the low-density material layer 2, the special adhesive coating 3, and the PET layer 4; the release agent coating uses silicone oil, and the low-density material layer adopts a density of 0.99g / cm 3 , LLDPE material with a thickness of 12μm, and a special adhesive coating with a density of 0.9g / cm 3 Heat-shrinkable LLDPE layer, PET layer with a density of 1.1g / cm 3 , PET material with a thickness of 125 μm.

[0044] The release agent coating 1 has the function of anti-adhesive isolation.

[0045] The low-density material layer 2 has the effect of separating the release agent coating 1 from the PET layer;

[0046] The special adhesive coating 3 has high bonding strength, and it is easy to fall off from the surface of the PET layer when washing with alkaline water or warm water, and will not remain on the surface of the PET layer;

[0047] The PET layer 4 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com