A tile-shaped NdFeB magnet and abrasive separation equipment

A separation equipment, neodymium iron boron technology, applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., can solve problems such as the inability to realize the separation of magnetic steel and abrasive materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

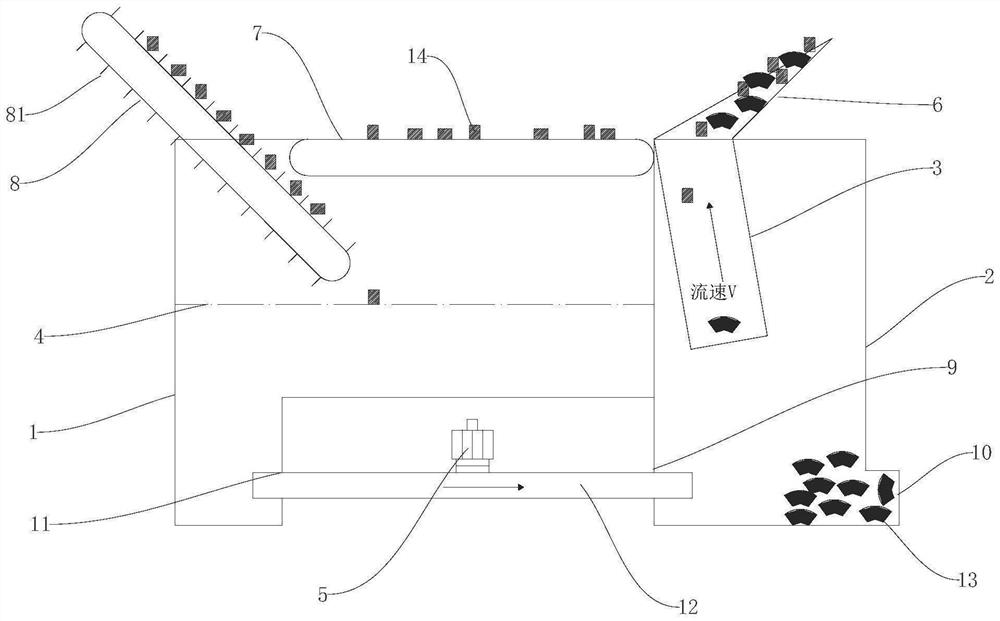

[0009] Example: as figure 1 As shown in the figure, a tile-shaped NdFeB magnet and abrasive separation equipment includes a water storage tank 1 with an upper end opening, a separation box 2 with an upper end opening, a separation pipe 3, an abrasive filter screen 4, a water pump 5, a feeding rail 6, The first endless conveyor belt 7, the second endless conveyor belt 8, the first drive mechanism for driving the first endless conveyor belt 7 to move, and the second drive mechanism for driving the second endless conveyor belt 8 to move, the water storage tank 1 is located on the left side of the separation box 2 On the left side, the lower left side of the separation box 2 is provided with a first opening 9, the lower right side of the separation box 2 is provided with a discharge port 10, the first opening 9 is facing the discharge port 10, and the separation pipe 3 is arranged in the separation box 2 , the upper end of the separation pipe 3 is flush with the upper end of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com