Self-compensation type electrified wire connection integrated installation device

An installation device and self-compensation technology, applied in the direction of cable suspension device, overhead line/cable equipment, etc., can solve the problems of thread locking, actual cable clamp operation trouble, failure of cable clamp parallel groove, etc., to achieve reliable clamping holding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

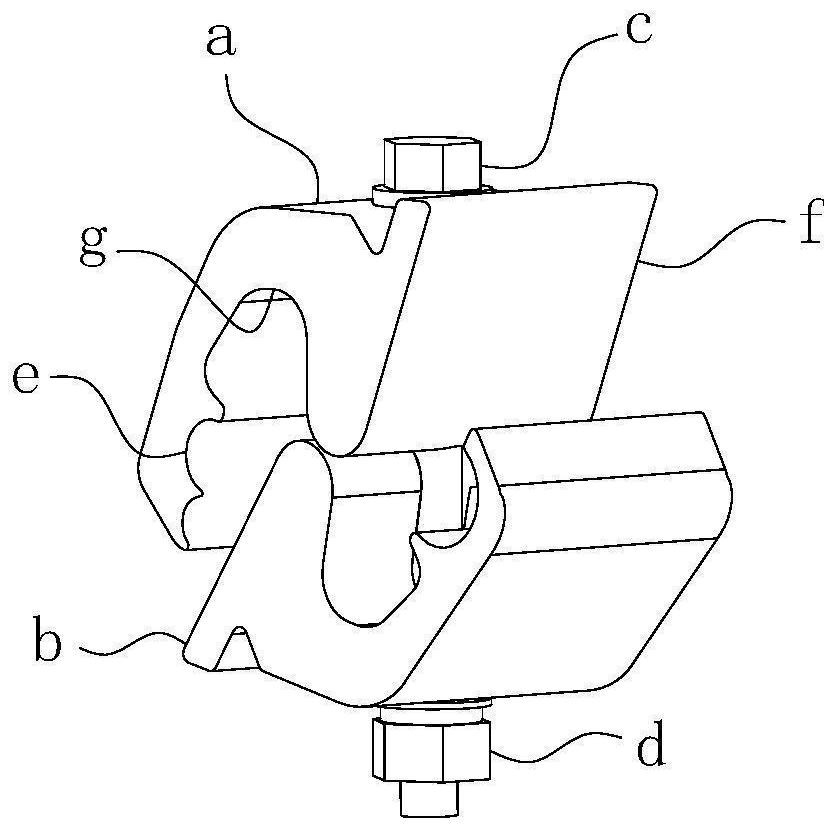

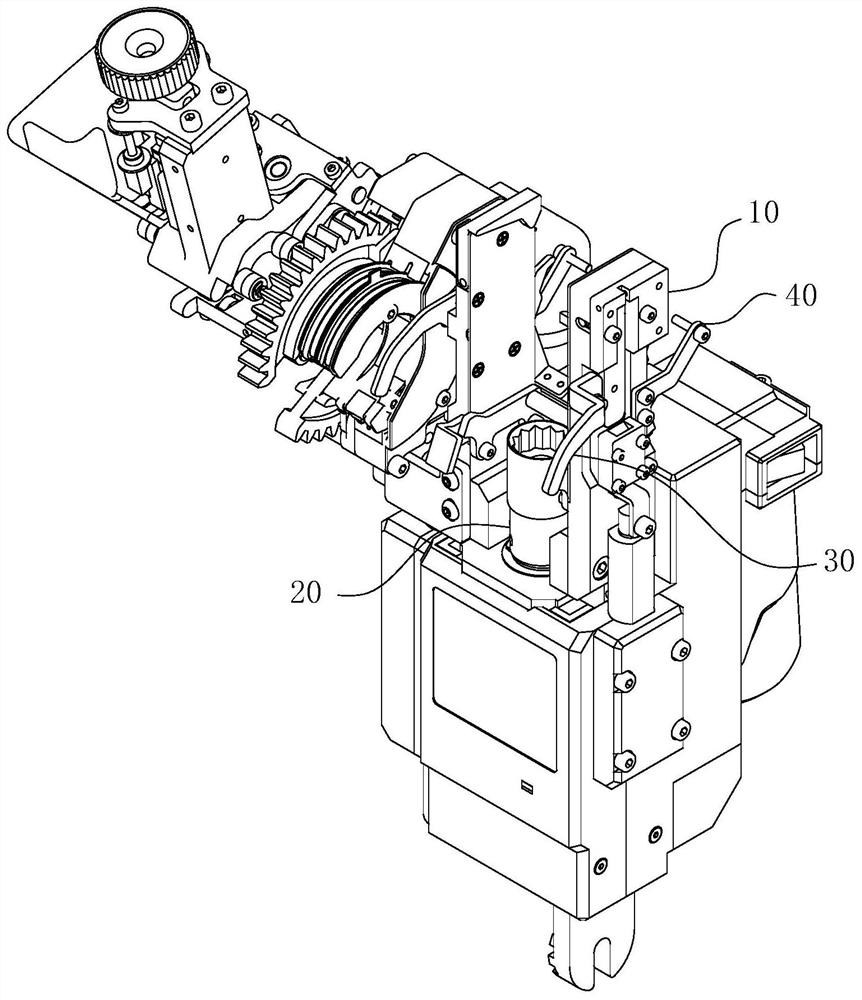

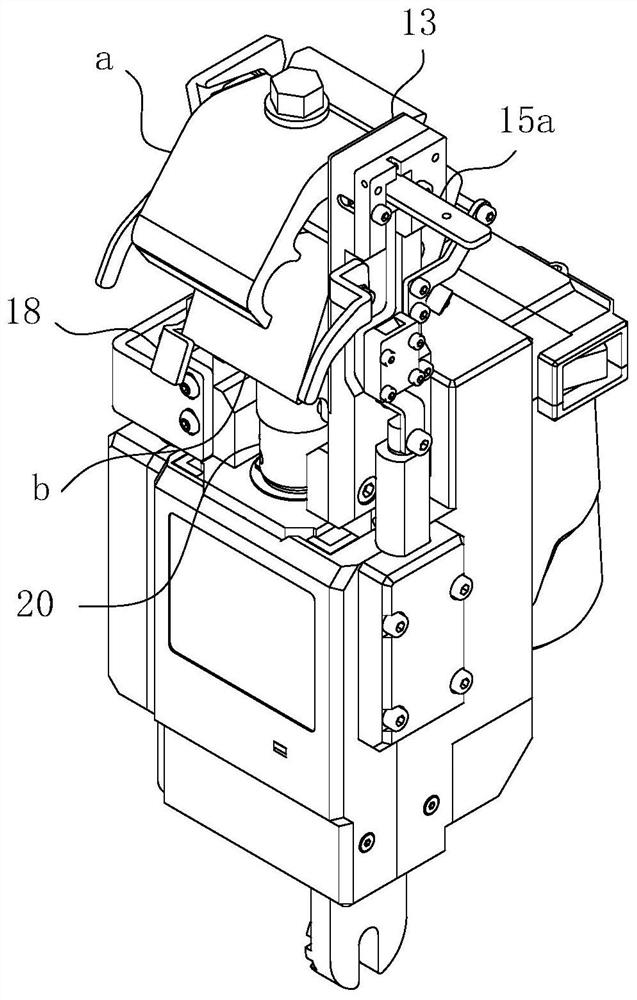

[0056] For ease of understanding, combined here Figure 1-13 , taking the installation and construction of the traditional J-shaped clamp (hereinafter referred to as the clamp) as an example, the specific structure and working method of the present invention are further described as follows:

[0057] The present invention can be used in remote control equipment such as robots; during actual assembly, the present invention can be fixed on the mechanical arm. At this time, since the main line is fixed as a reference object, the present invention can be lifted by the mechanical arm to complete the relative main line. The hook-type parallel ditch operation.

[0058] During the actual work of the present invention, its concrete structure is as Figure 2-13 As shown, its main structure includes a positioning installation part 10 for fixing the wire clip, a striking part 20, a secondary wire locking clip 40 for fixing the secondary wire B, and a main wire guiding clip 30 for loading...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com