Quickly-mounted transfer layer crane support structure and construction method thereof

A support structure and layer crane technology, which is applied in the direction of building components, building structures, buildings, etc., can solve the problems of health threats to construction workers, unfavorable use of electricity, and low construction safety, so as to reduce on-site welding and ensure stability High performance, easy and flexible installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

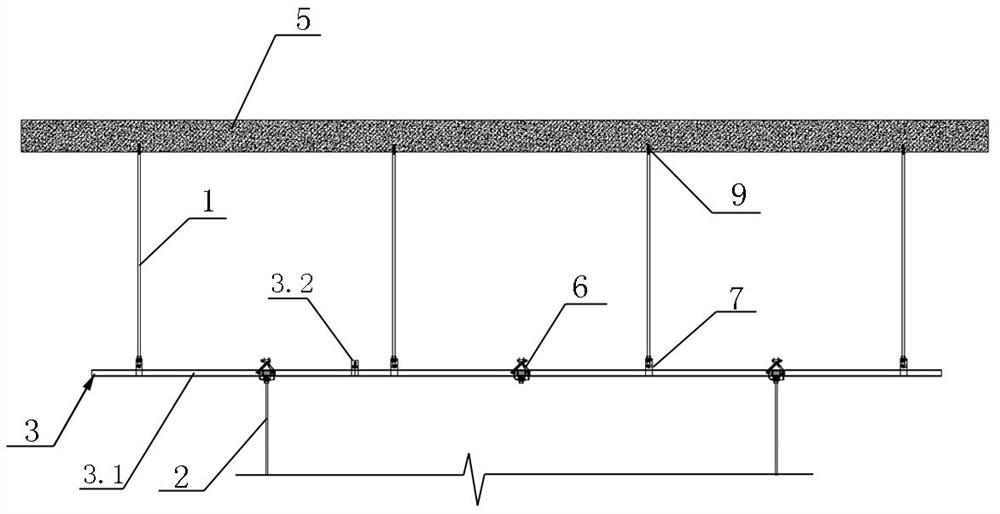

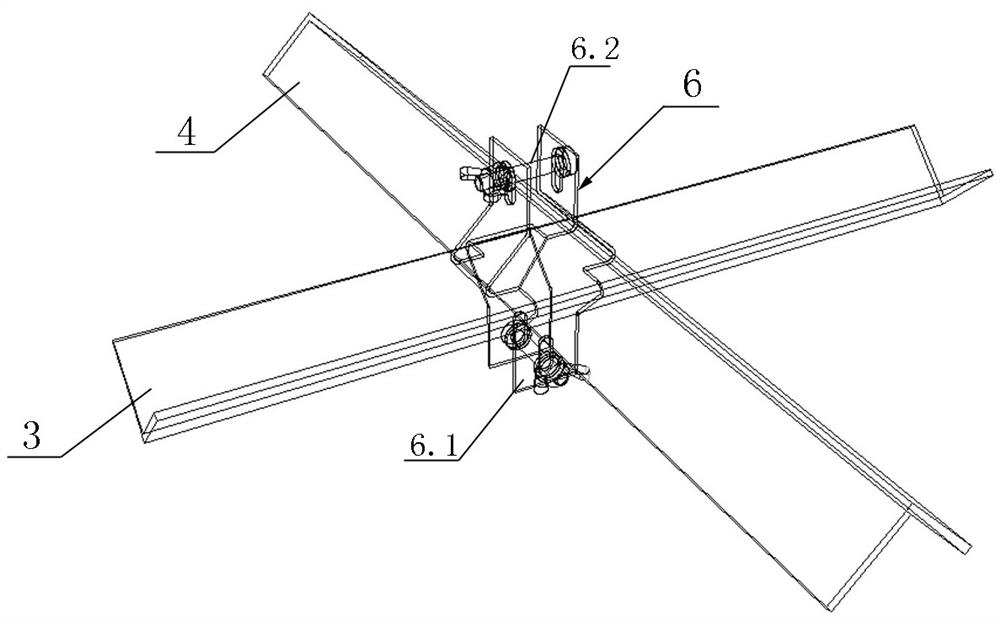

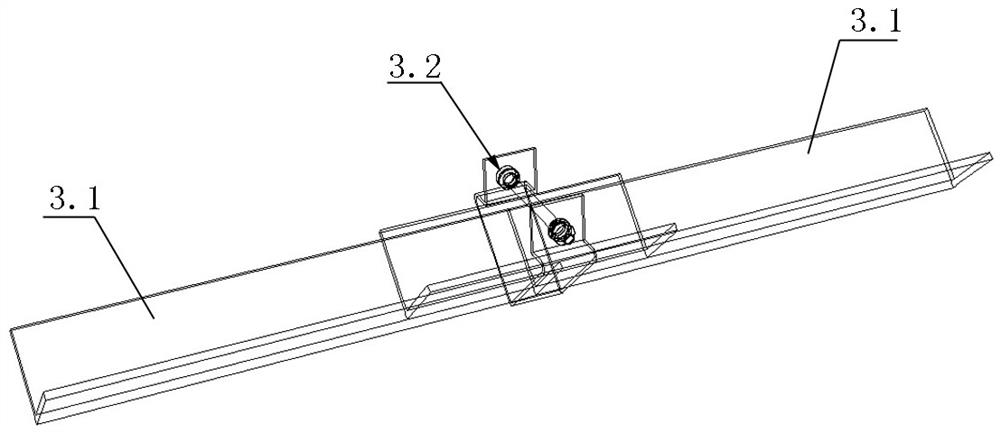

[0043] Such as Figure 1-12 As shown, this fast-installation transfer layer hanger bracket structure includes an upper boom 1, a lower boom 2, a transverse keel 3 and a longitudinal keel 4; the transverse keels 3 have a group and are arranged at intervals along the longitudinal direction; the longitudinal keels There is one group of 4, which are arranged at intervals along the transverse direction on the top of a group of transverse keels 3, and a group of longitudinal keels 4 and a group of transverse keels 3 jointly form the keel skeleton; the upper boom 1 is arranged with a set of , used to hang the keel frame below the floor 5; the lower boom 2 has a group, and a group is arranged on each longitudinal keel 4, which is used to hang the ceiling board under the keel frame; the transverse keel 3 and the longitudinal keel 4 are made of angle steel, and the notch of the transverse keel 3 faces upward, and the notch of the longitudinal keel 4 faces downward; the transverse keel 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com