Patents

Literature

79results about How to "Accurate readout" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

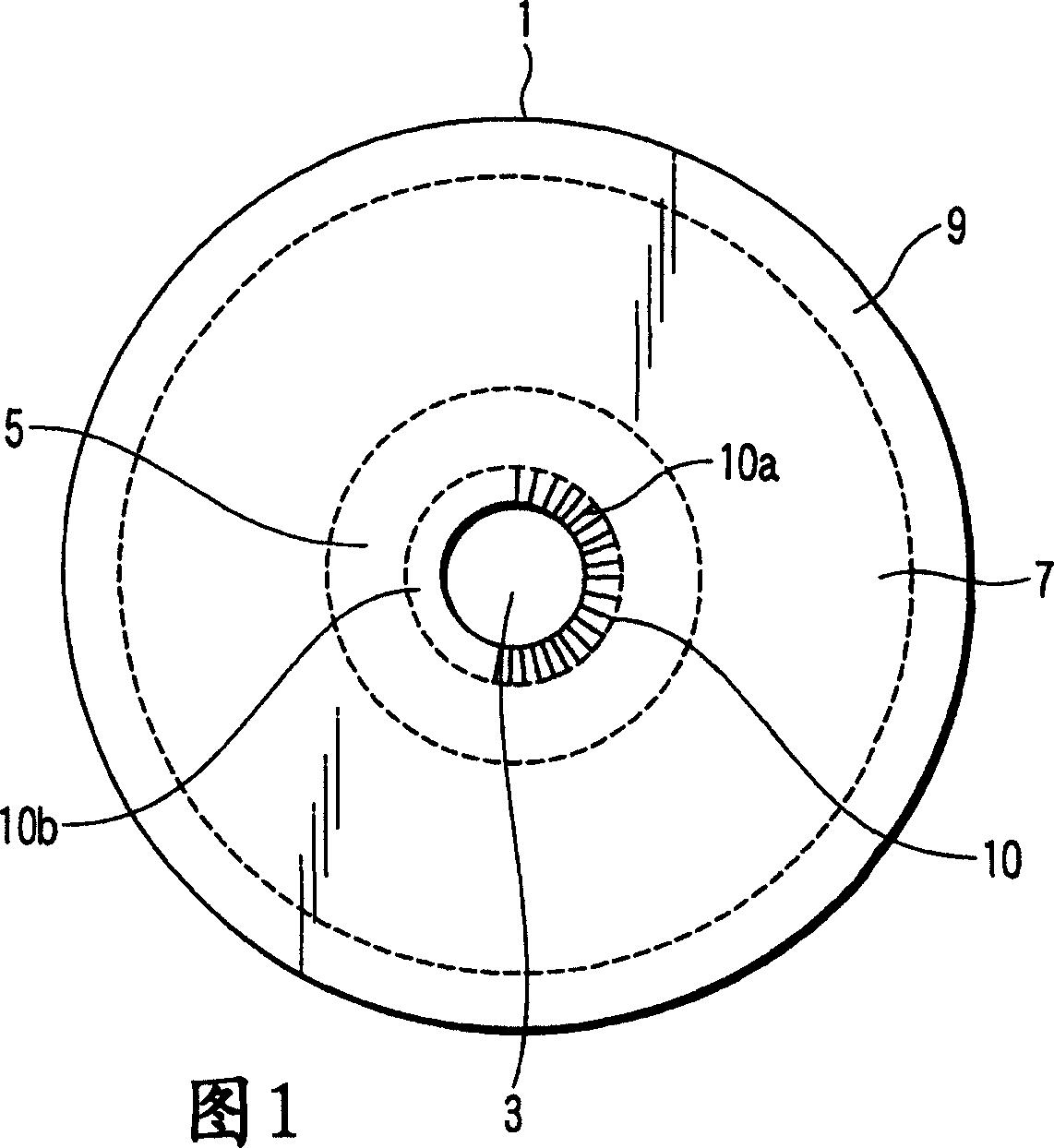

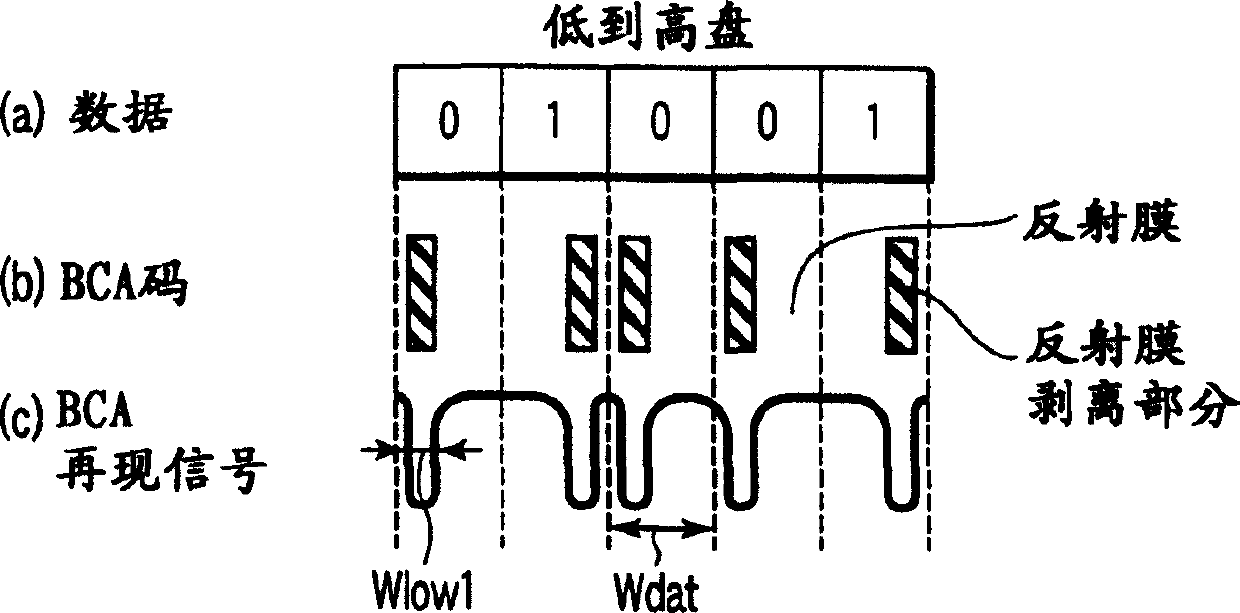

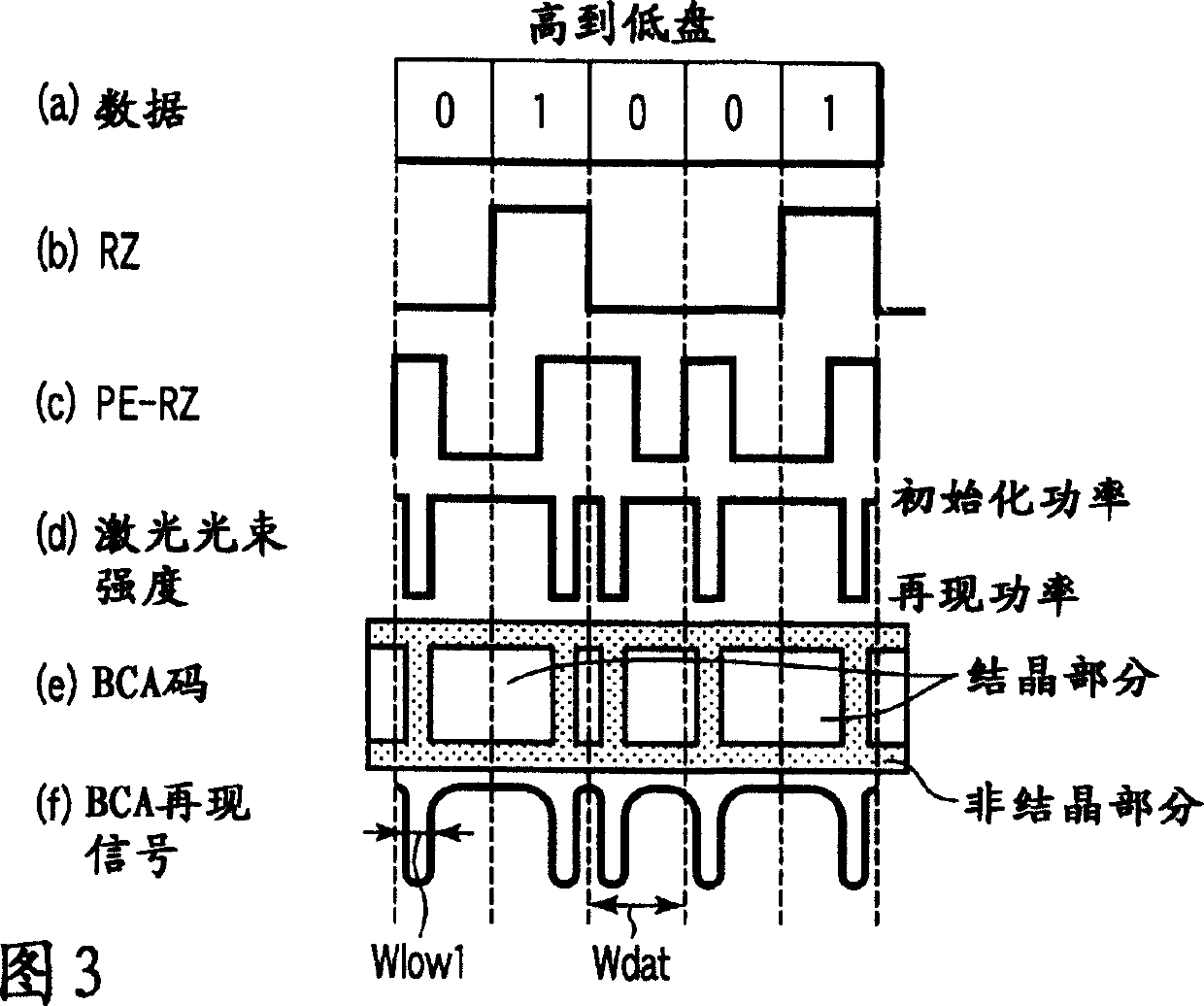

Optical disk, optical disk apparatus, optical disk recording and reproduction method, and apparatus and method for recording BCA code

InactiveCN1627375AImprove reflectivityChange reflectivityOptical beam sourcesRecord information storageOptical recordingReflectivity

A disc (1) has a burst cut area (BCA) (10) formed by a crystalline part and an amorphous part, and the disc (1) is an optical disc in which the reflectance of the crystalline part is lower than that of the amorphous part ( L-H medium). The width Wcry of the crystalline portion in the BCA(10) is less than half of the data period Wdat. Therefore, the average level of the BCA reproduction signal does not change regardless of whether the optical disc is an HL medium or an L-H medium, so that focus control and BCA code reproduction can be performed even if the circuit parameters are default values.

Owner:TOSHIBA SAMSUNG STORAGE TECH KOREA CORP

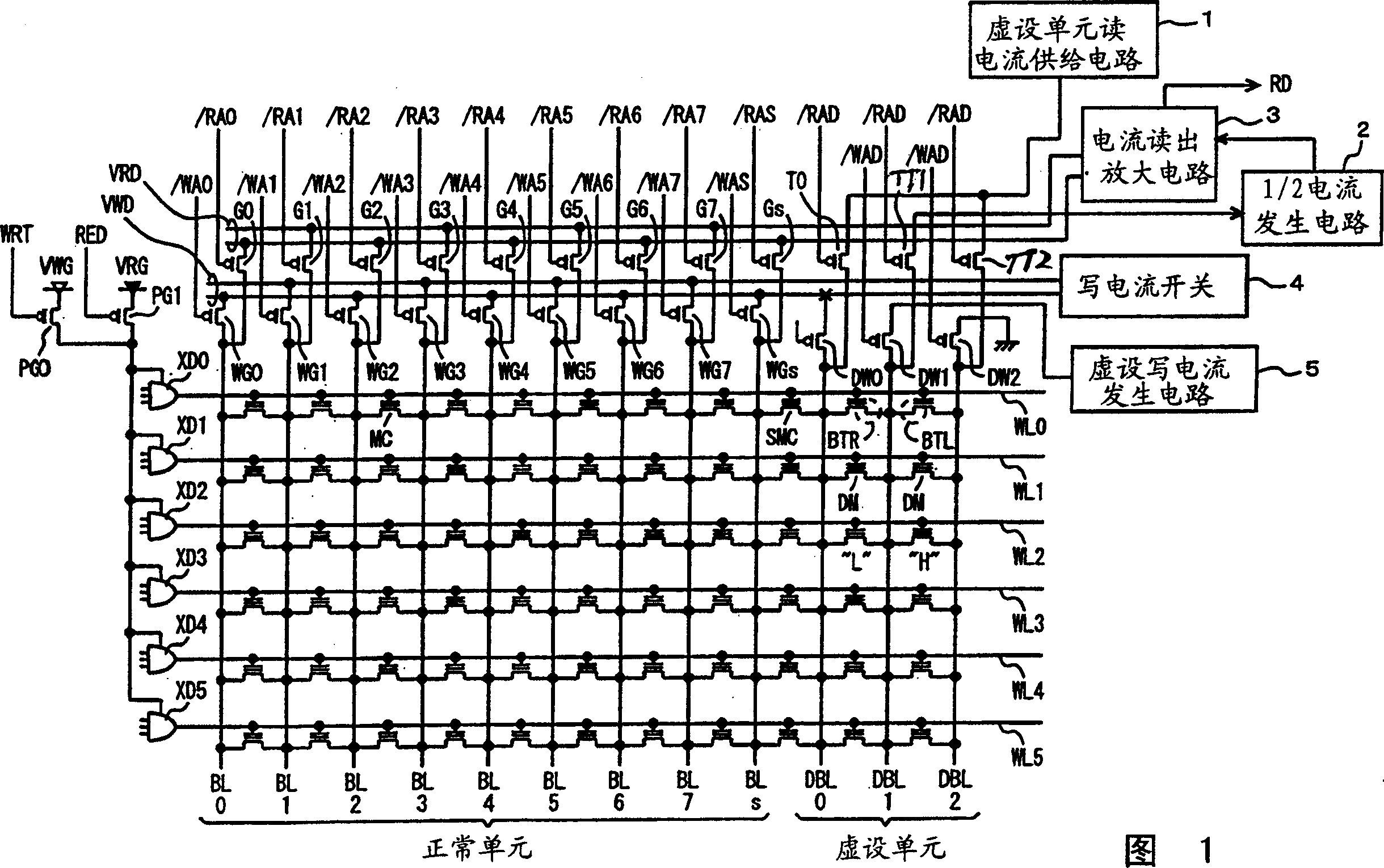

Nonvolatile memory for catching charges in isolative films

InactiveCN1440038AAccurate detectionHigh speed readoutTransistorSolid-state devicesAverage currentNormal cell

Dummy cells in an erased state and in a write state are used to generate a dummy current corresponding to the average current of currents flowing in the dummy cells using a 1 / 2 current generating circuit, and the dummy current is compared with a current corresponding to a memory cell current flowing in a selected normal cell using a current sense amplification circuit to generate internal read data according to a result of the comparison. With such a configuration, a non-volatile semiconductor memory device capable of reading data at high speed can be achieved.

Owner:MITSUBISHI ELECTRIC CORP

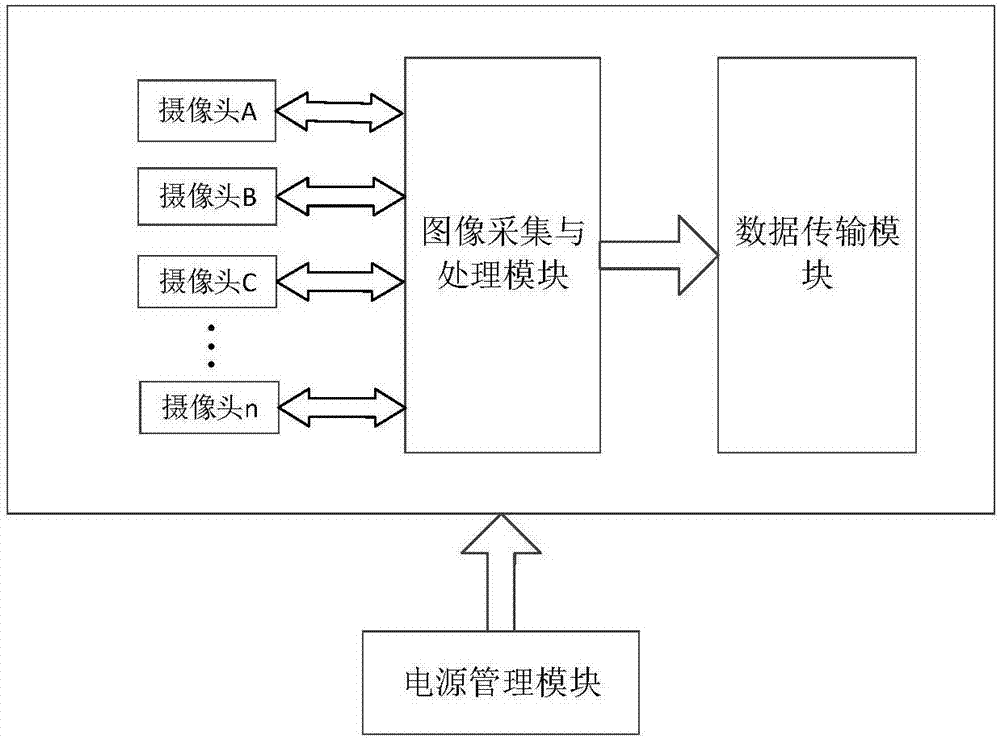

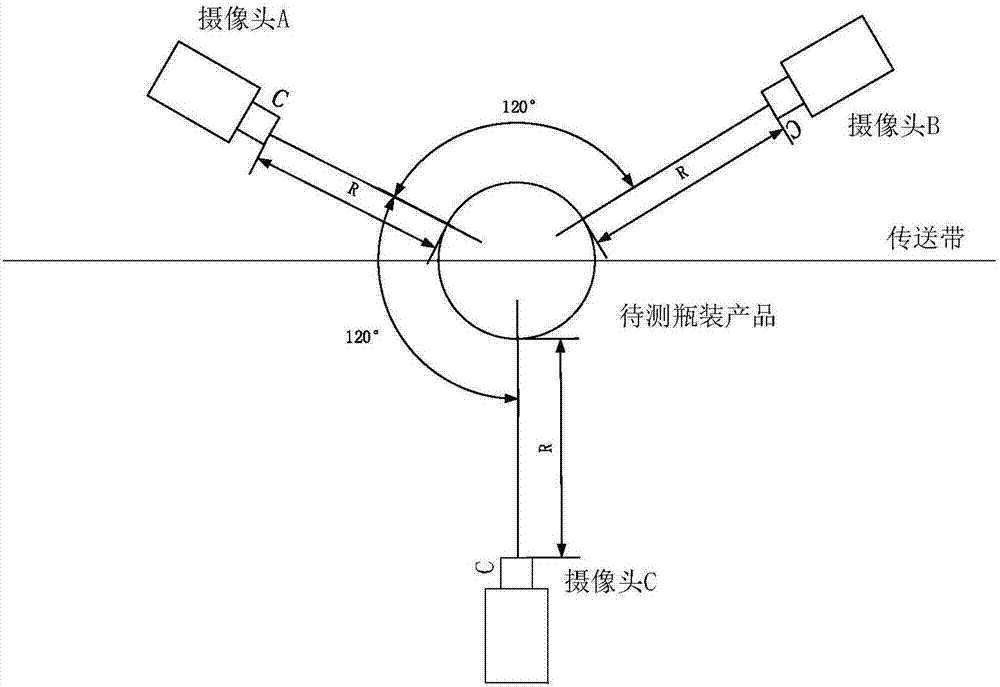

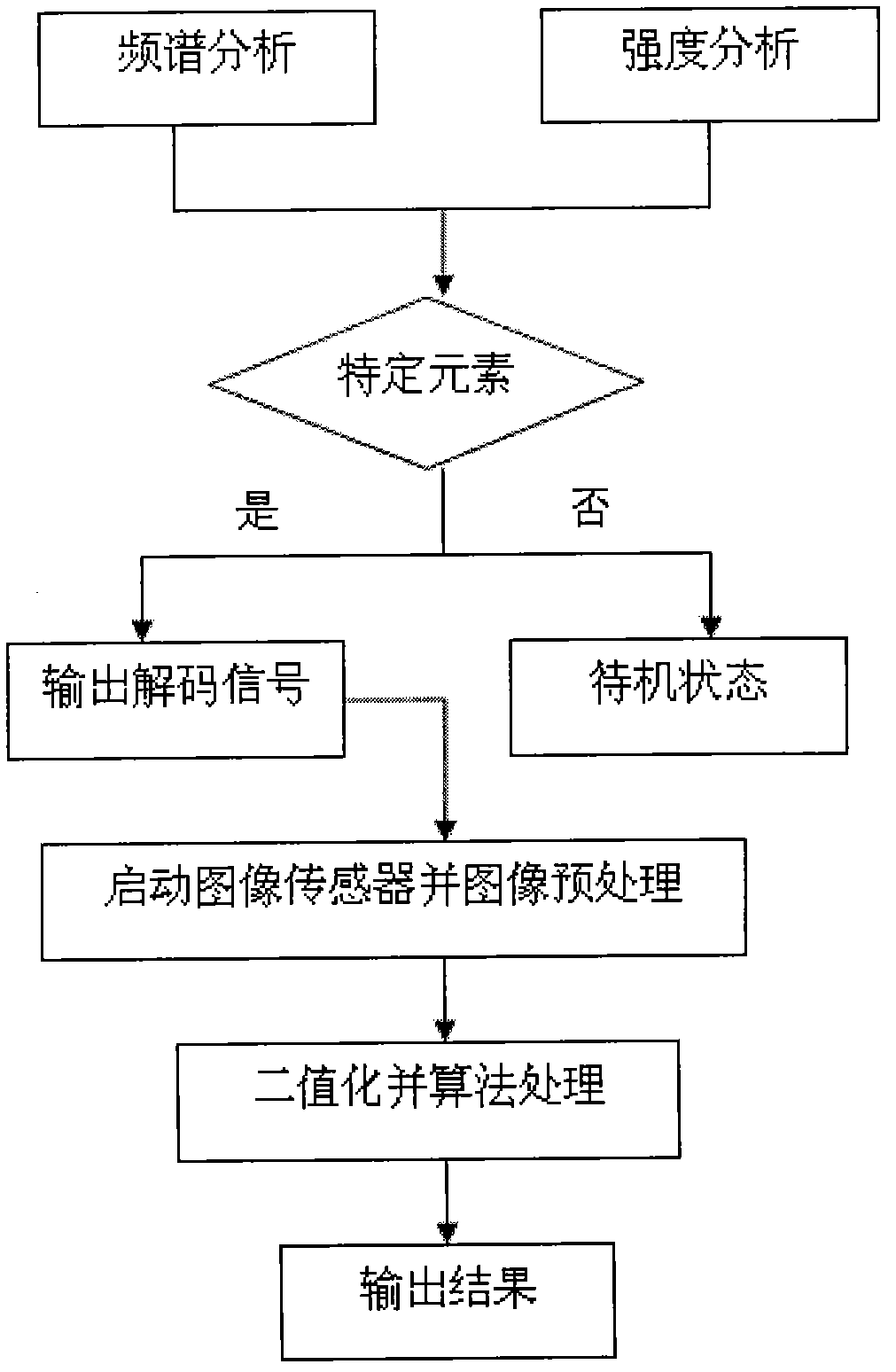

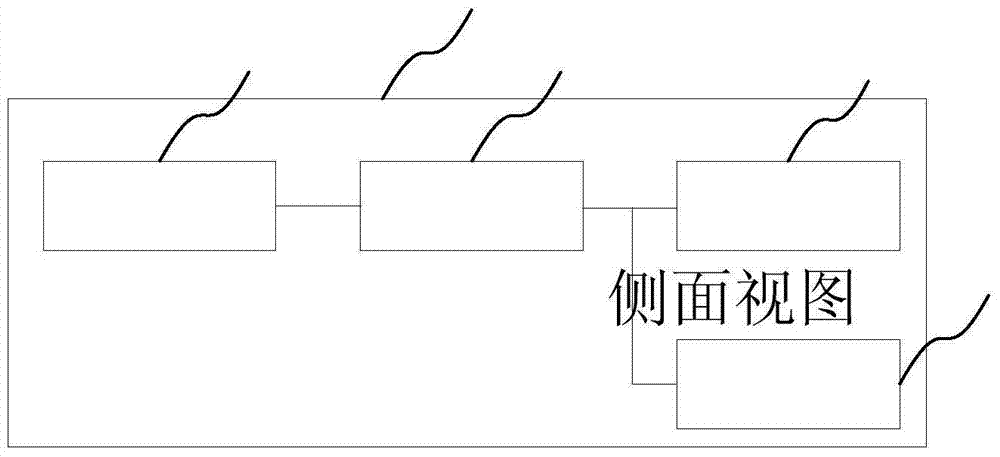

Omnibearing bar code identification device and method

InactiveCN107145810AFast readoutAccurate readoutSensing by electromagnetic radiationSupply managementComputer module

The present invention discloses an omnibearing bar code identification device and method. The device comprises n cameras, an image acquisition and processing module, a data transmission module and a power supply management module. The cameras are all connected with the image acquisition and processing module, the image acquisition and processing module is connected with the data transmission module, and the power supply management module is connected with the cameras, the image acquisition and processing module and the data transmission module separately and is used to supply power to the cameras, the image acquisition and processing module and the data transmission module. The method comprises the steps of acquiring the side surface images of different directions shot by the n cameras; pre-processing the images; correcting the images; splicing the images; analyzing the bar codes; and transmitting the bar code information. According to the present invention, with the arrangement of the plurality of cameras, the bar code information pasted in any direction of the product side surfaces can be identified via software, and the omnibearing bar code identification device and the omnibearing bar code identification method have the characteristics of being fast in speed, low in power consumption, high in accuracy and good in versatility.

Owner:NANJING UNIV OF SCI & TECH

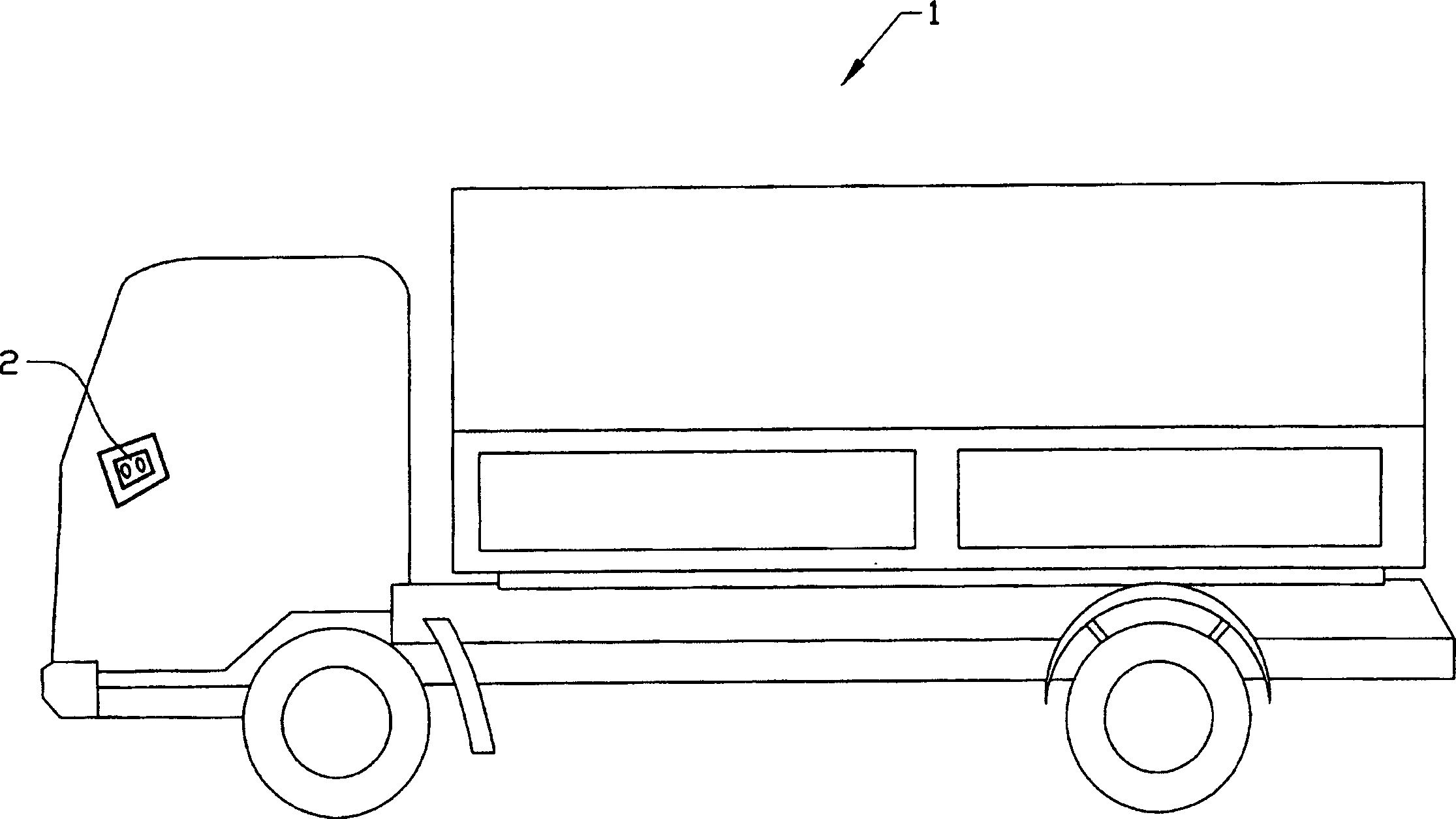

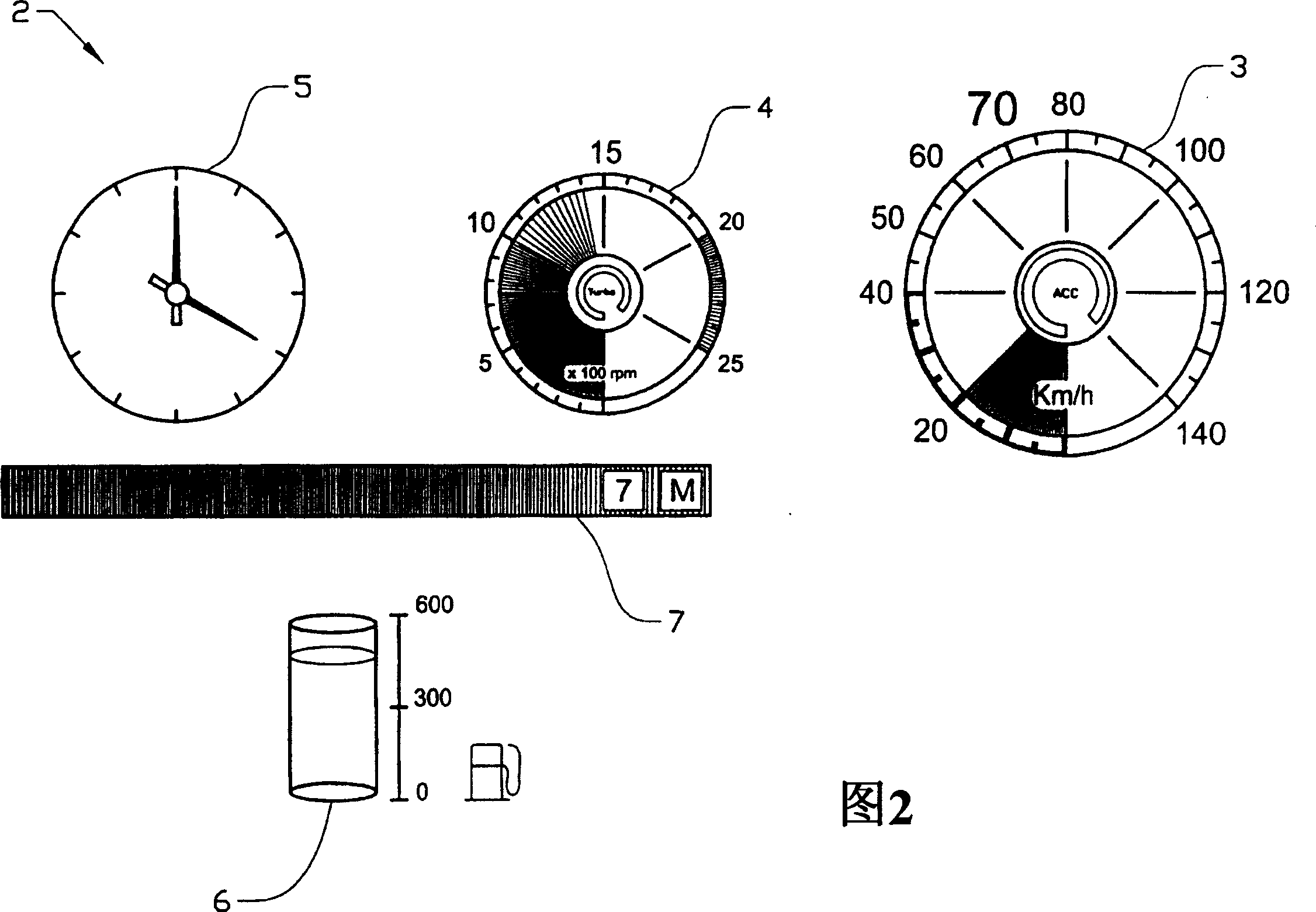

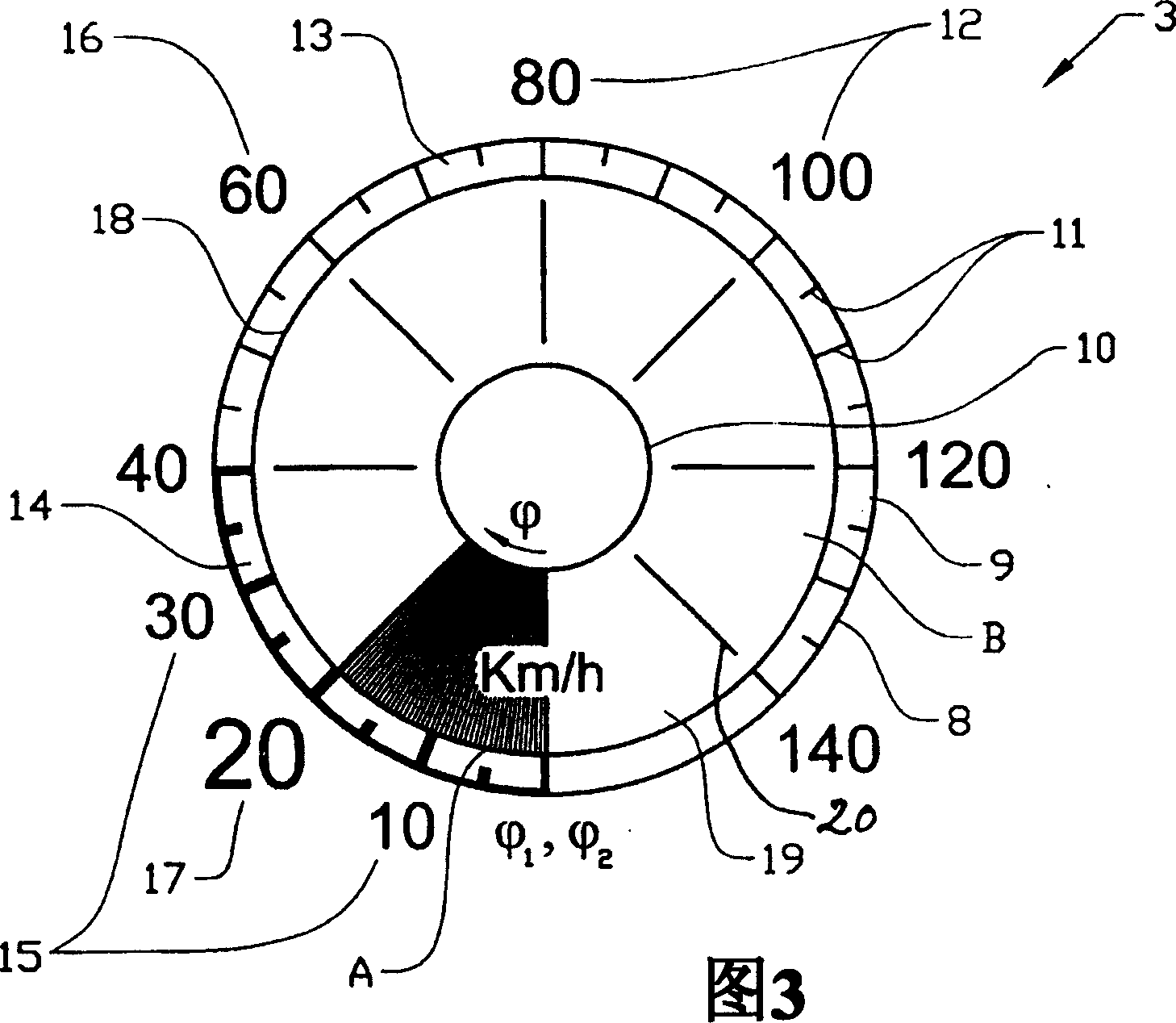

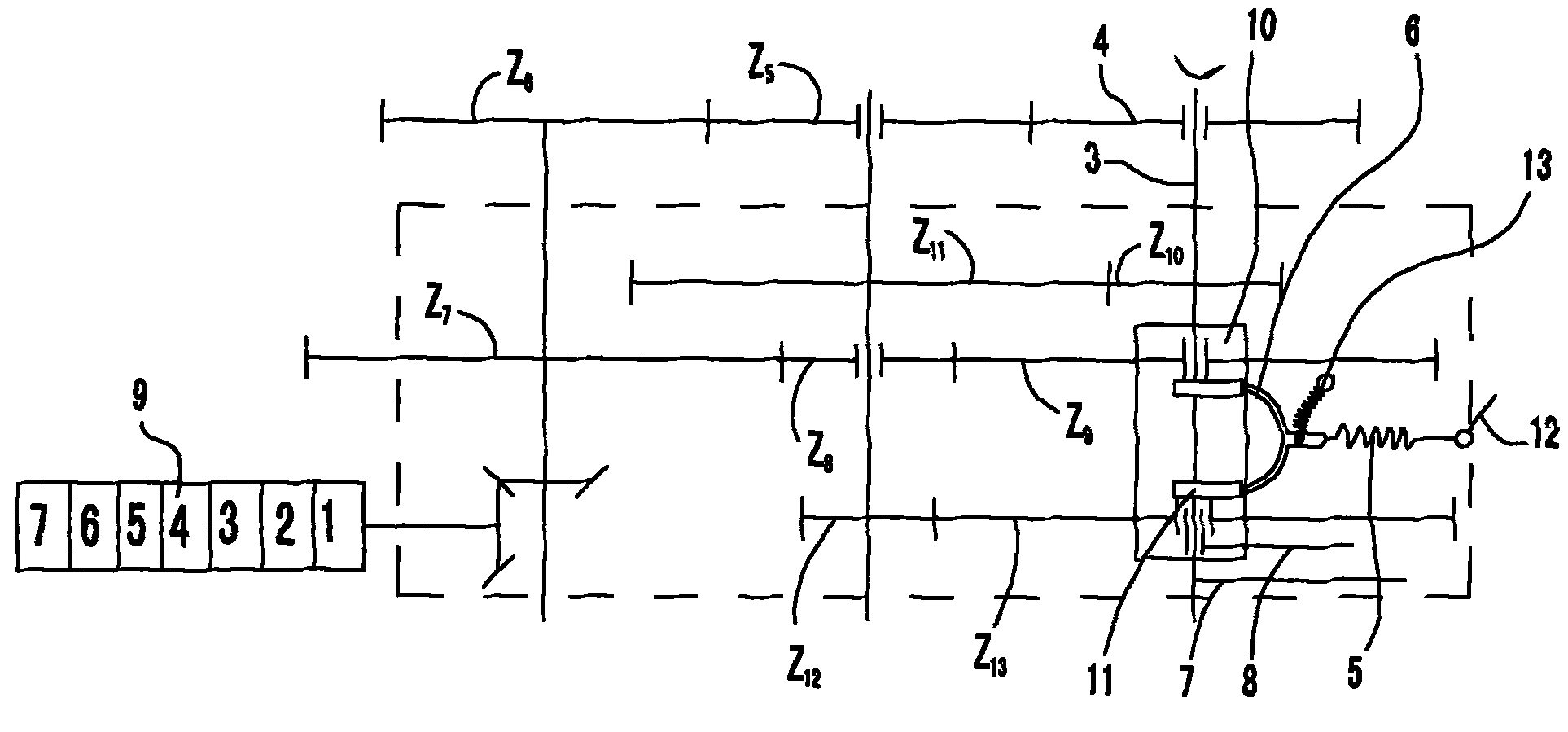

Device for indicating an operational state of a vehicle

InactiveCN1655962ARead quickly and correctlyAccurate readout of operating statusIndication apparatusInstrument arrangements/adaptationsDisplay deviceEngineering

Display device for indicating an operational state of a vehicle including a display unit, where the device shows graphical information on the display unit in the form of an arc-shaped scale and a number of numerals corresponding to the value of the operational state. The device includes an arc-shaped field with an extent from a first angle phi1 to a second angle phi2 and with an outer delimiting line that extends along the inside of the arc-shaped scale. The arc-shaped field is divided into a first segment A, which extends from the first angle phi1 to a third variable angle phi, and a second segment B, which extends from the third variable angle phi to the second angle phi2, where the third variable angle phi to the second angle phi2. The third variable angle phicorresponds to the relevant operational state of the vehicle and where phi1<=phi<=phi2, where the first segment A is arranged to assume a state that is visually distinguishable from the second area B.

Owner:VOLVO TECH

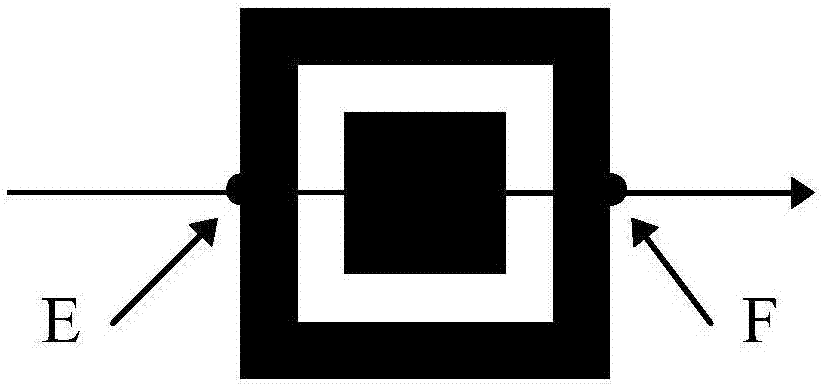

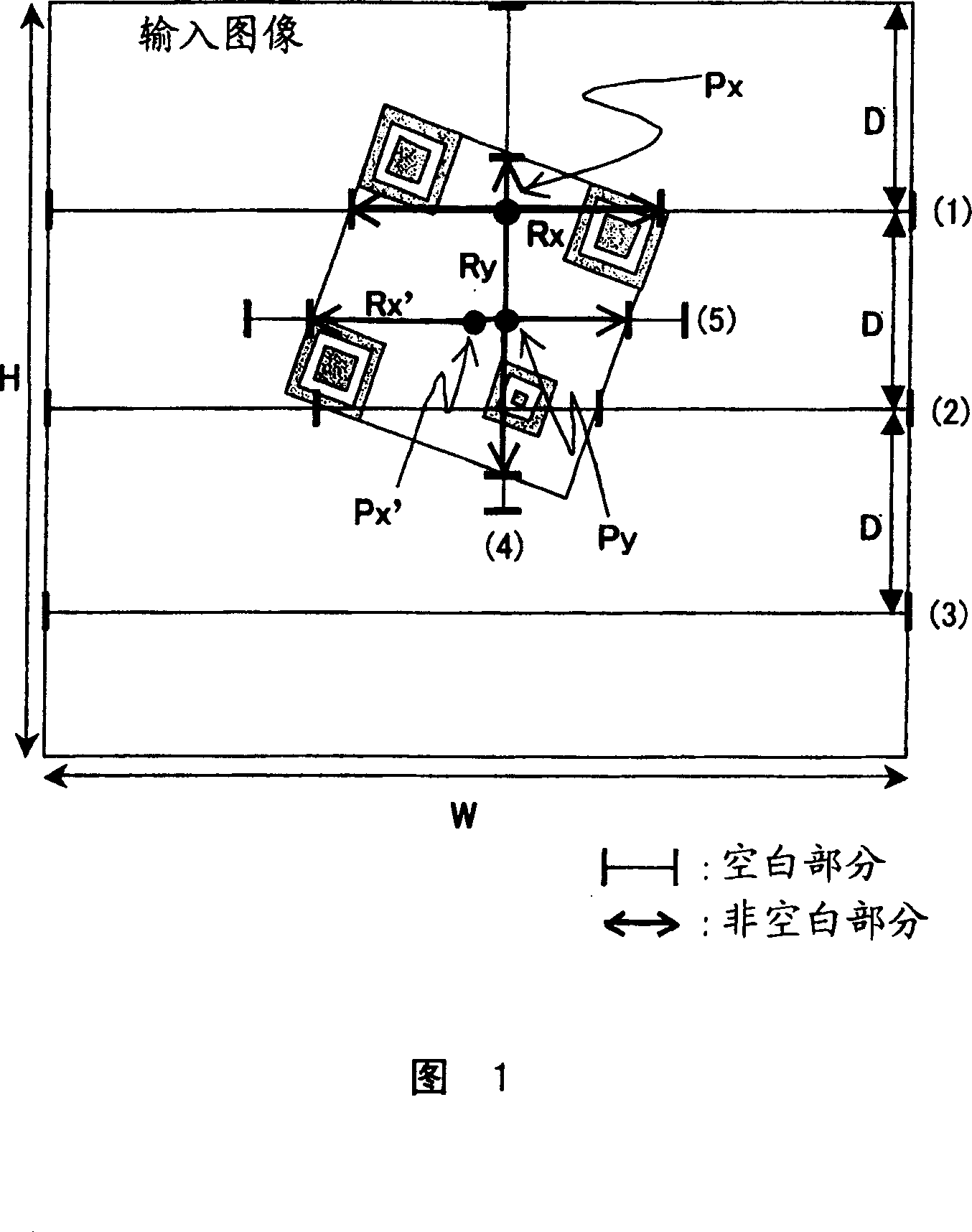

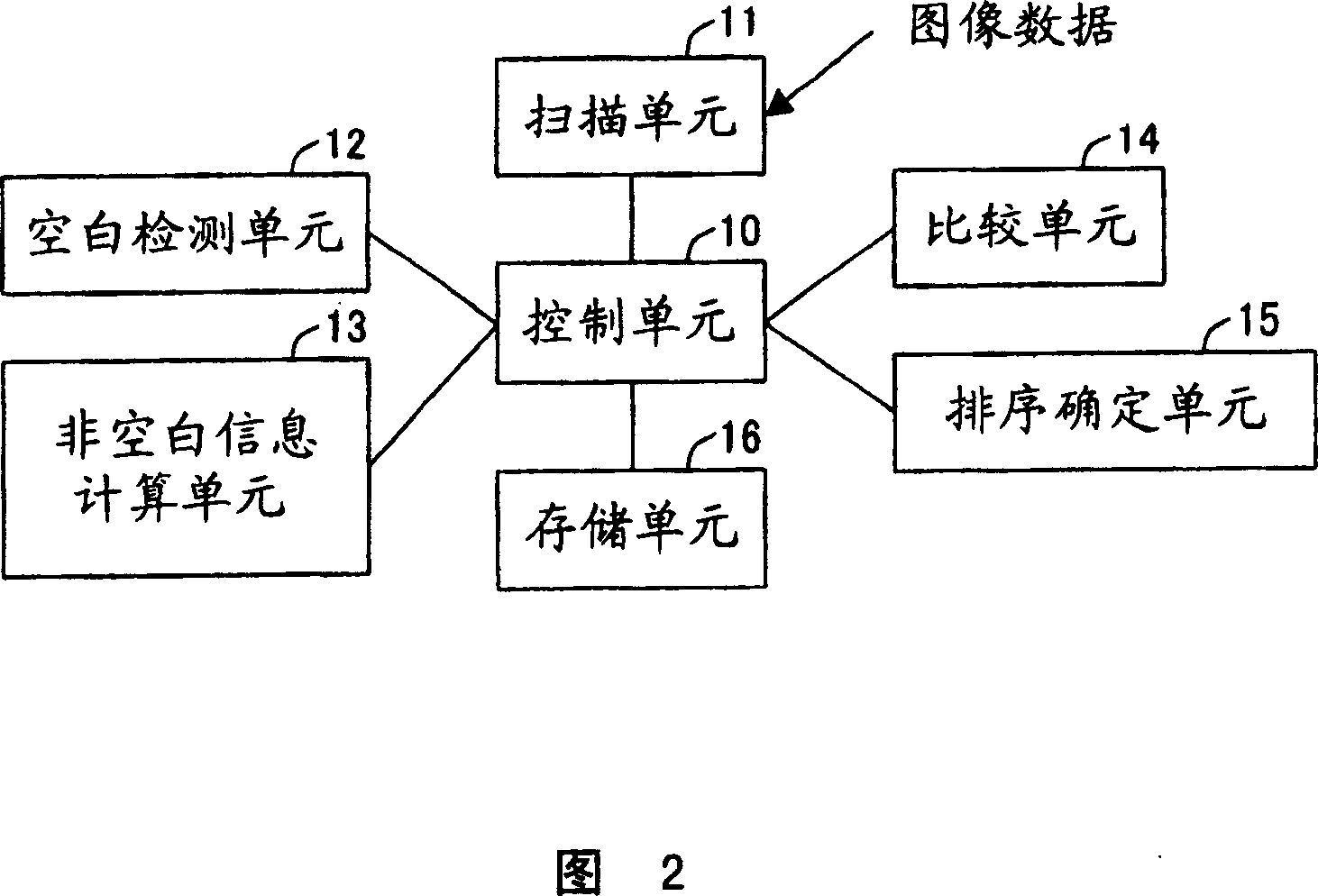

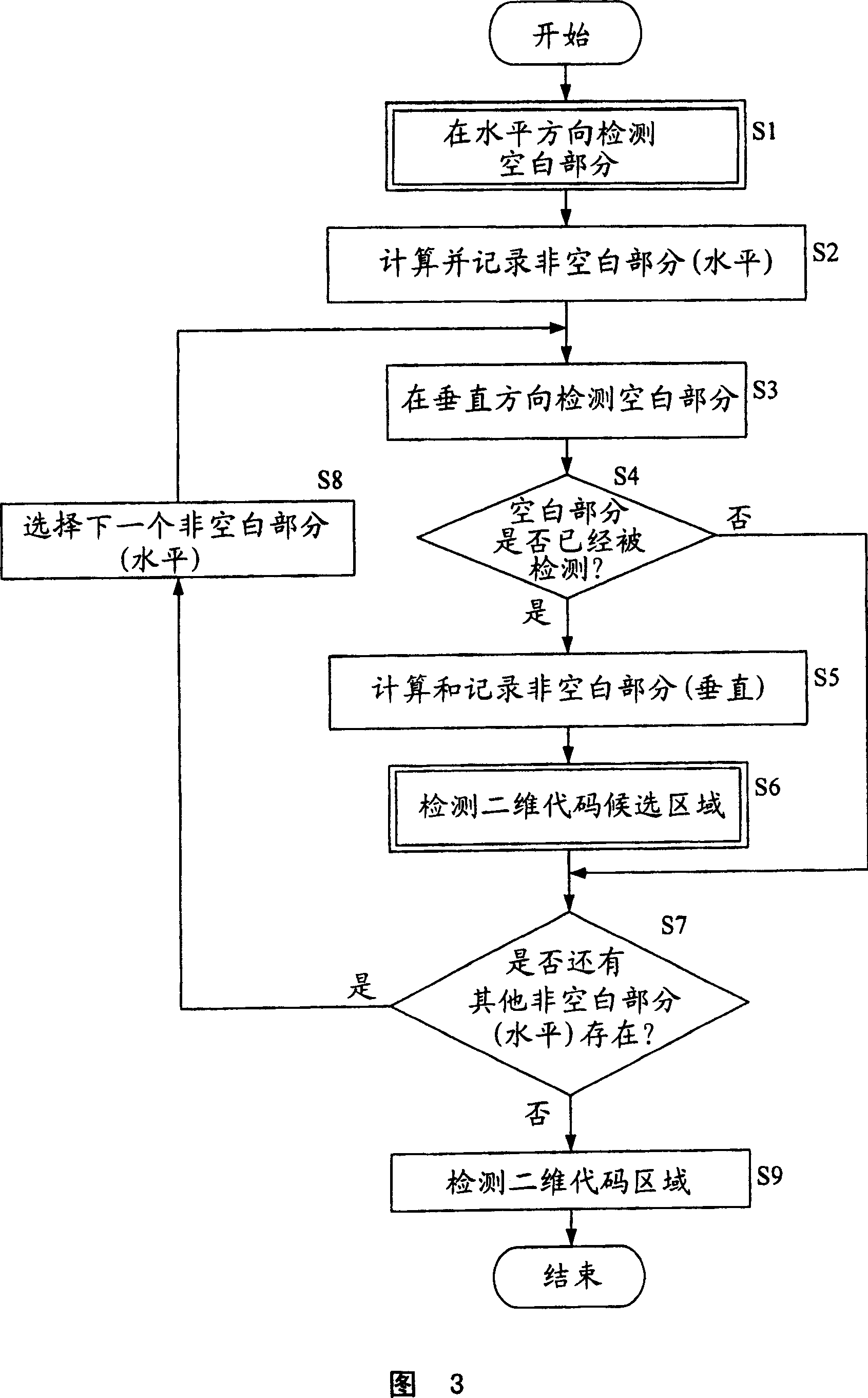

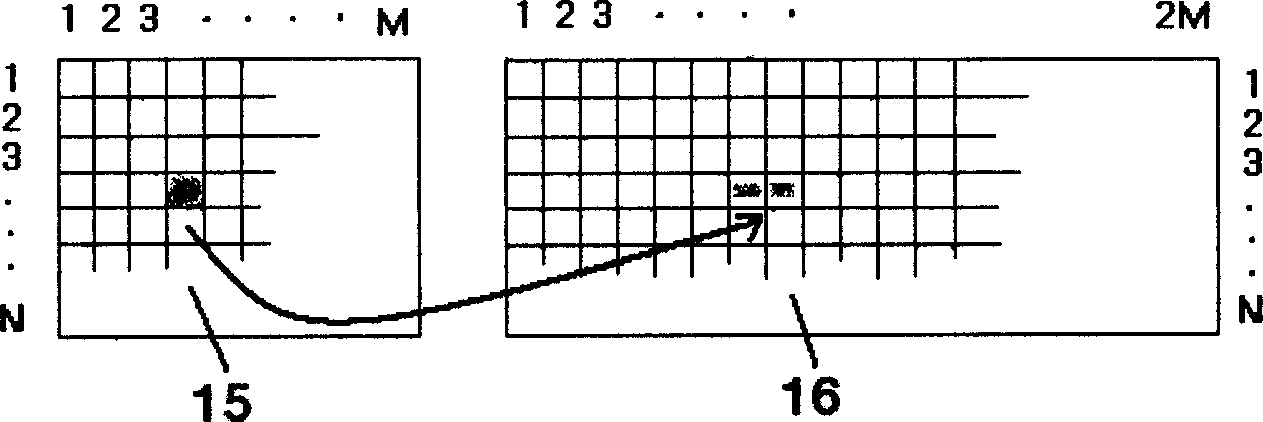

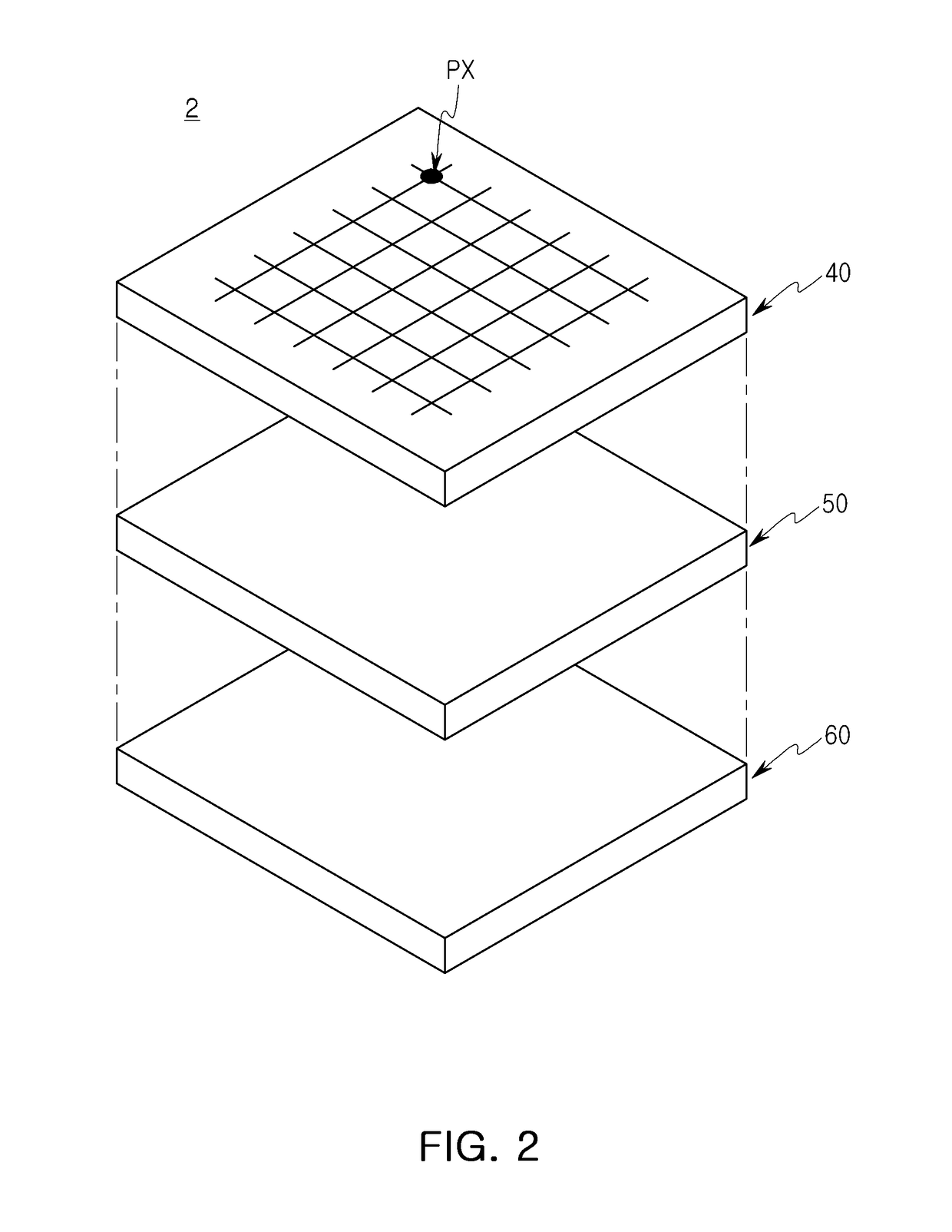

2-dimensional code region extraction method, 2-dimensional code region extraction device, electronic device, 2-dimensional code region extraction program, and recording medium containing the program

InactiveCN1950828AAccurate readoutSensing by electromagnetic radiationComputer graphics (images)Algorithm

A 2-dimensional code region extraction device (1) includes a scan unit (11) for longitudinally / laterally scanning image data containing a 2-dimensional code, a blank space detection unit (12) for judging white / black gradation of the pixel scanned and detecting a blank space, a non-blank space information calculation unit (13) for calculating a distance to the non-blank space existing between the detected blank spaces and its center coordinate, a comparison unit (14) for comparing the length of the non-blank space existing in the longitudinal and lateral direction with its center coordinate so as to judge whether a 2-dimensional code exists, and an order decision unit (15) for comparing a plurality of 2-dimensional code candidate regions detected and ranking the 2-dimensional candidate regions.

Owner:SHARP KK

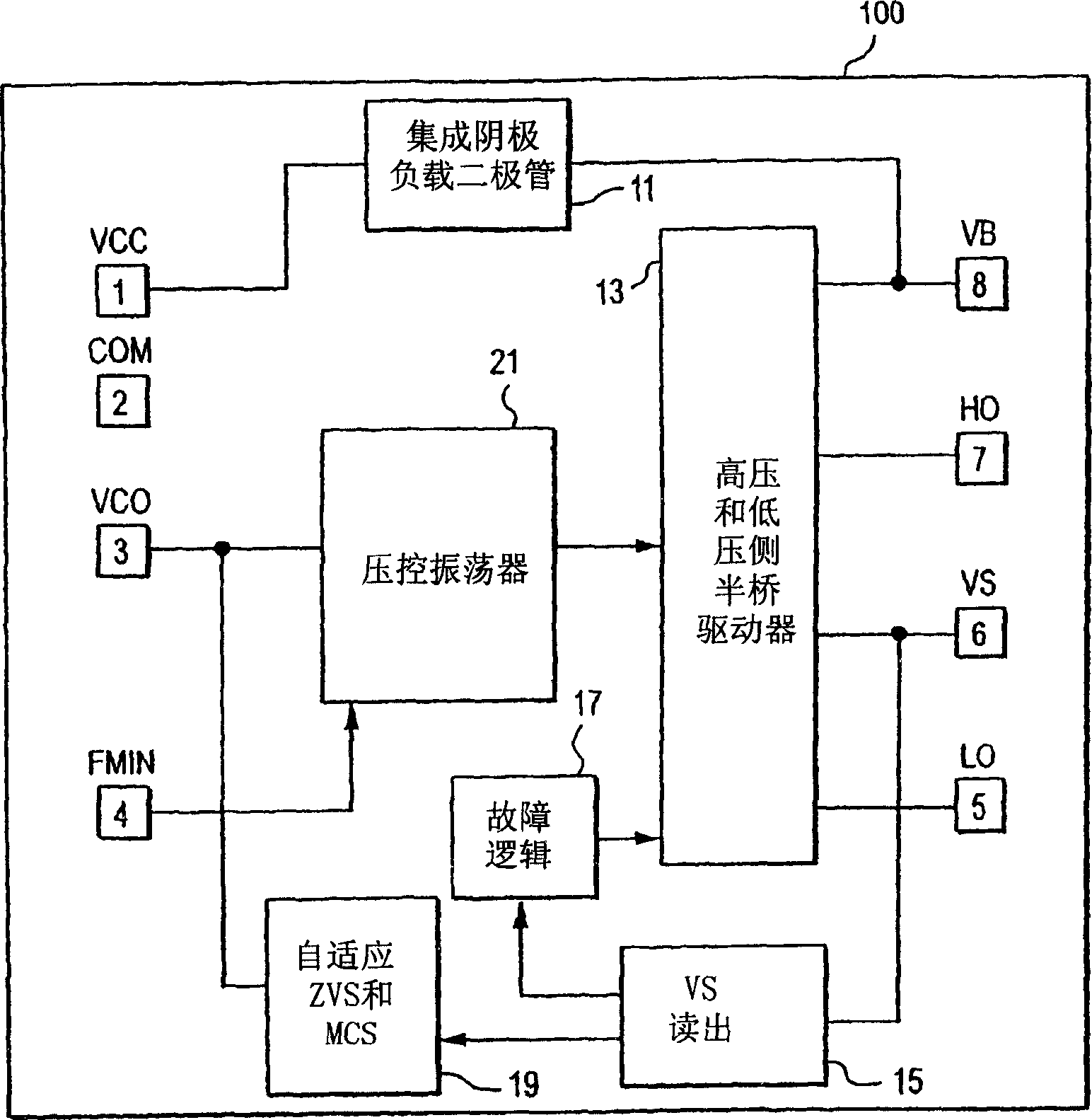

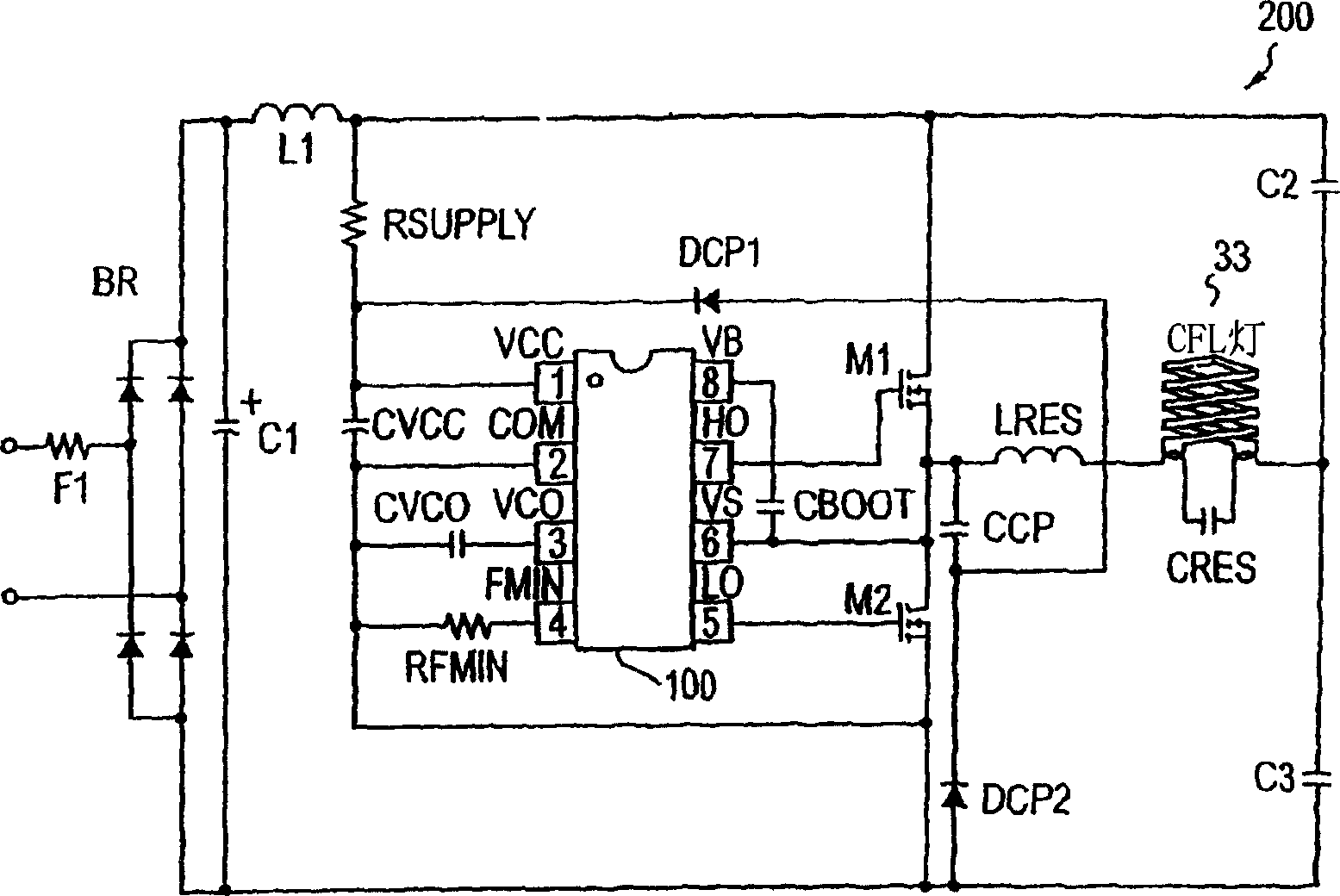

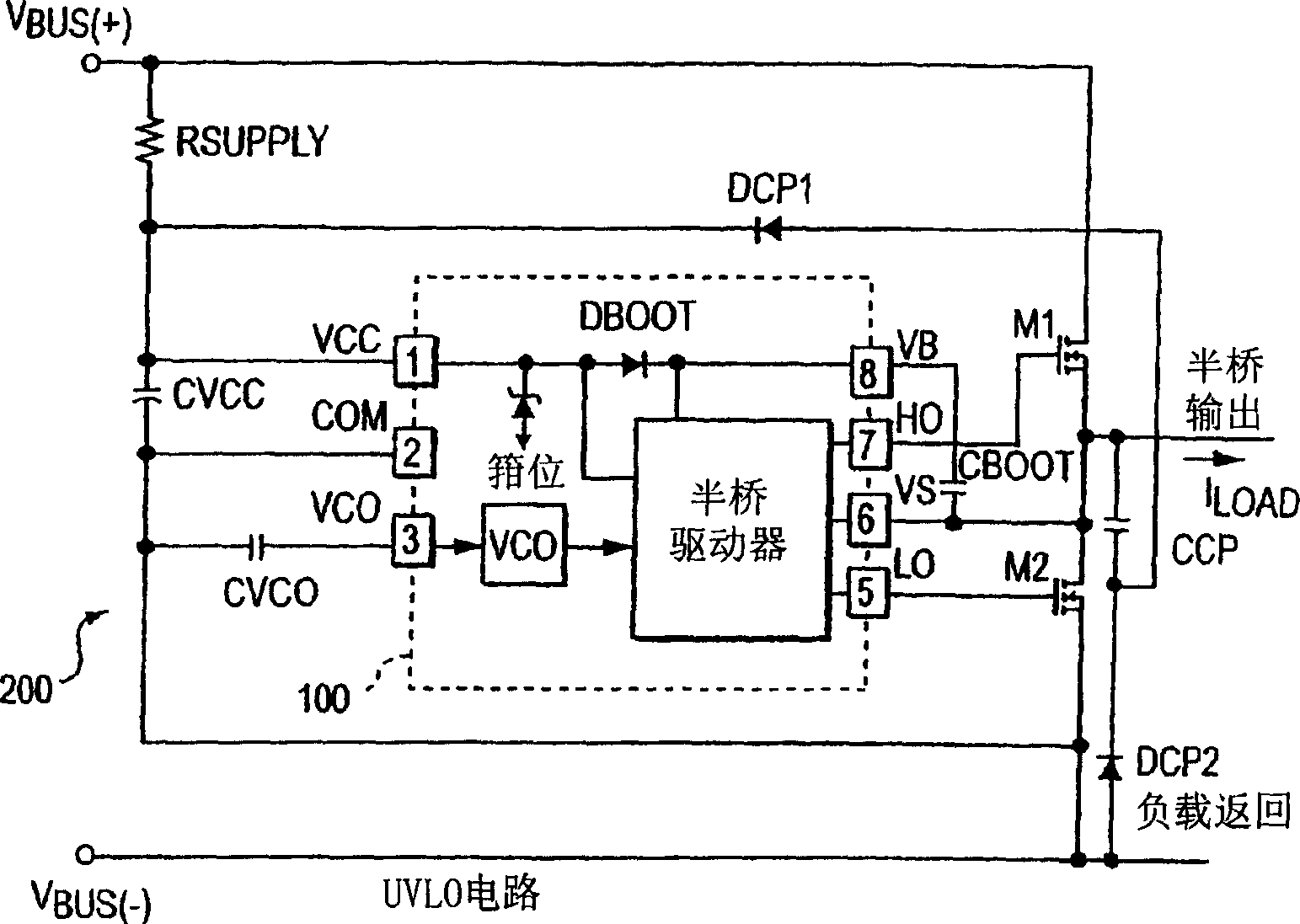

Adaptive CFL control circuit

InactiveCN1695099APackage cost is minimizedReliable preheatingGas discharge lamp usageElectric variable regulationSwitching frequencyFeedback circuits

An electronic ballast provides fault detection and safety features for overcurrent protection and hard switching at a half bridge. A voltage controlled oscillator supplies a switching frequency that is modifiable based on operational feedback parameters. A feedback circuit senses load current and output voltage to determiner fault conditions and to provide control information for adaptively adjusting the frequency of the voltage controlled oscillator. By appropriately controlling the voltage controlled oscillator output, the electronic ballast maintains a zero volt switching with minimum current switching to achieve an efficient and robust electronic ballast control. The entire control is integrated on a single integrated circuit.

Owner:INTERNATIONAL RECTIFIER COEP

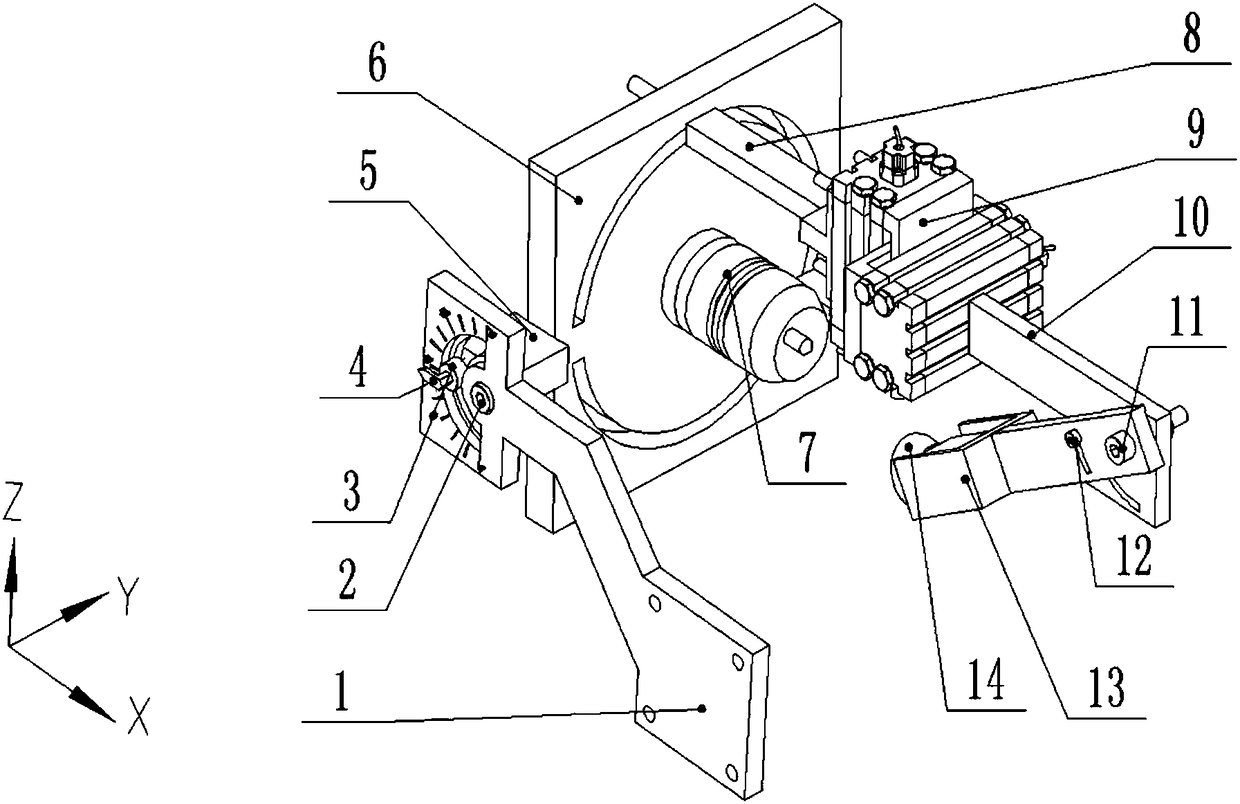

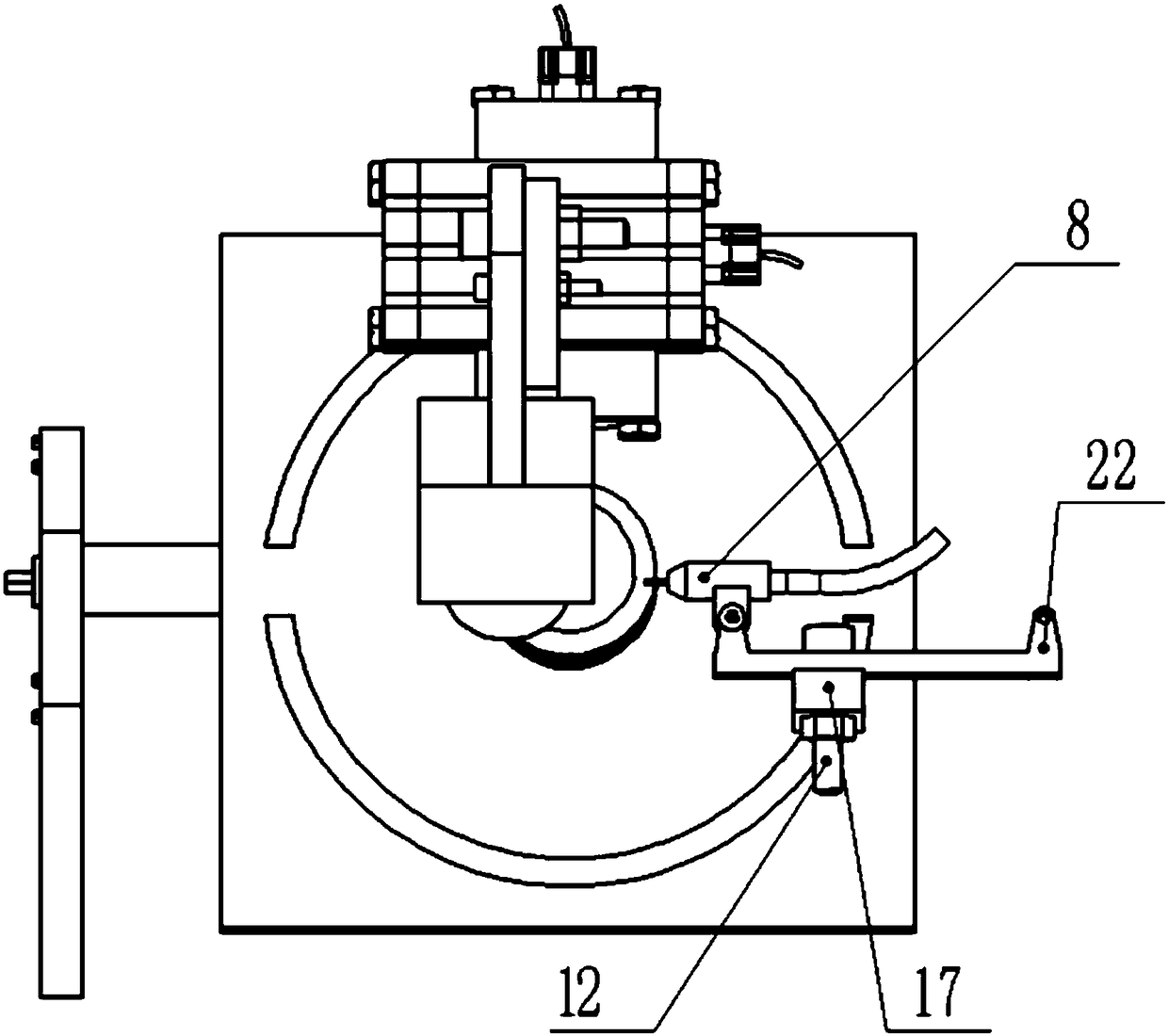

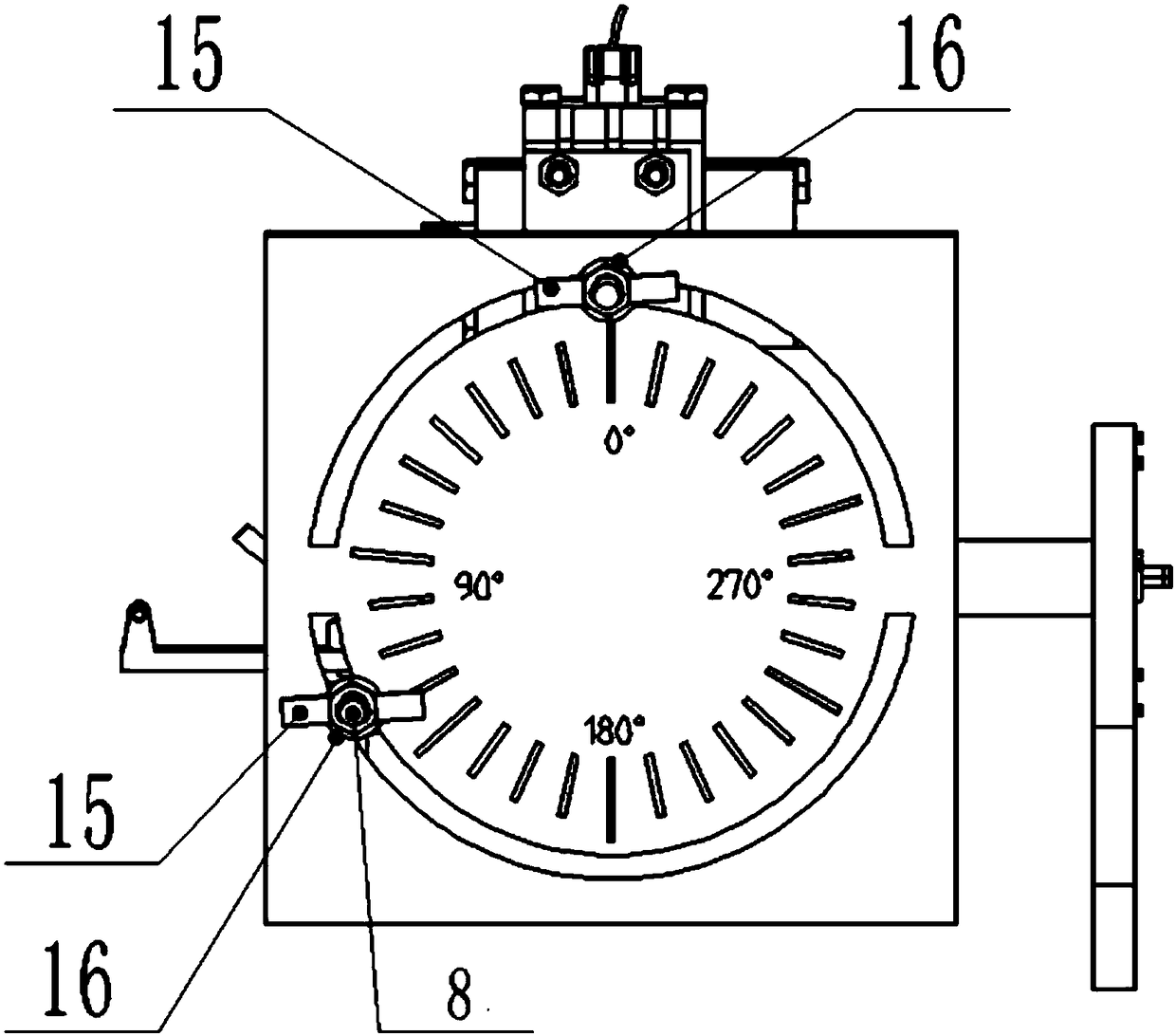

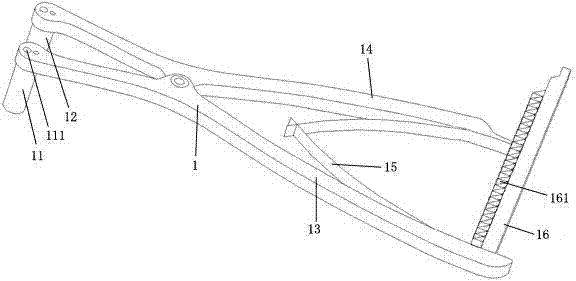

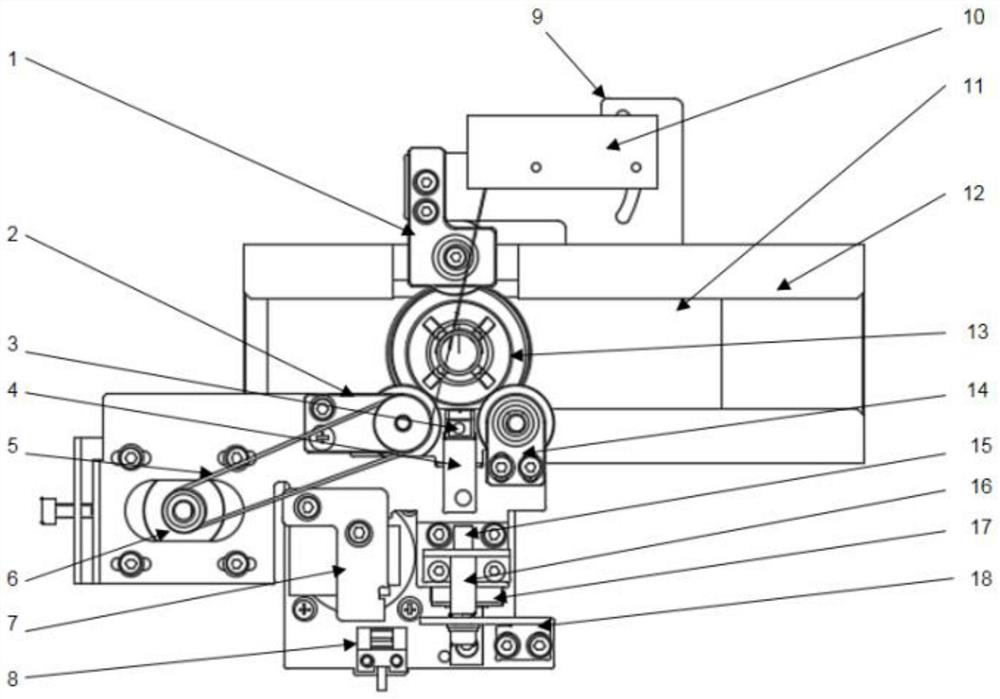

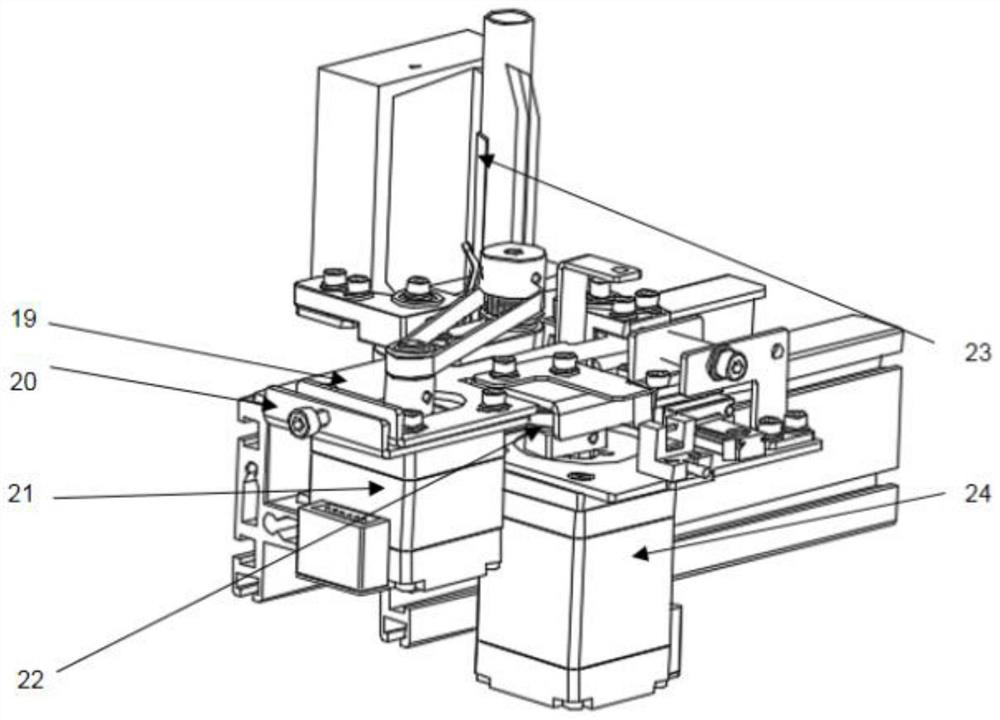

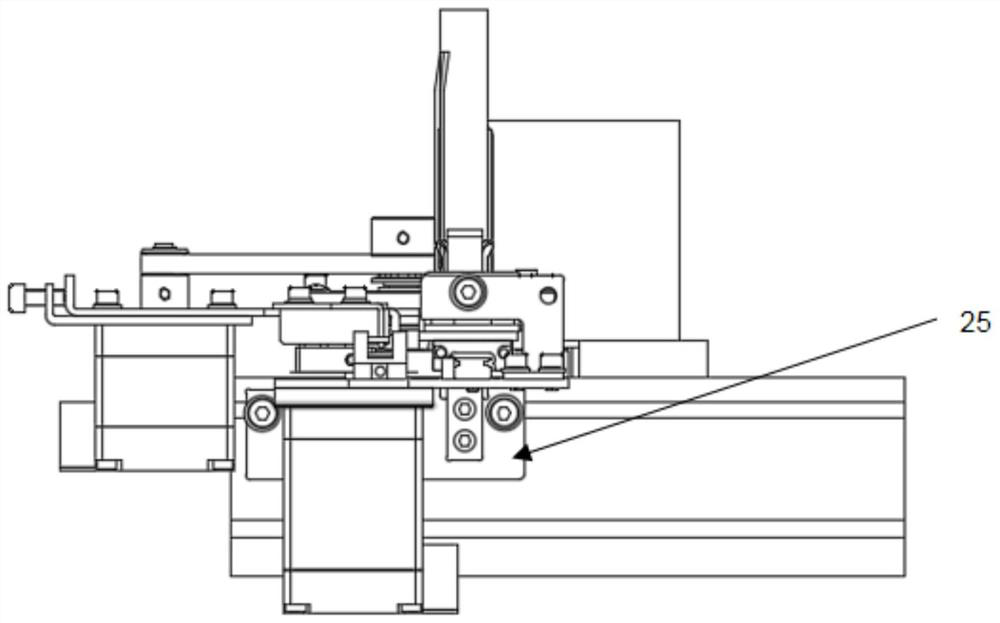

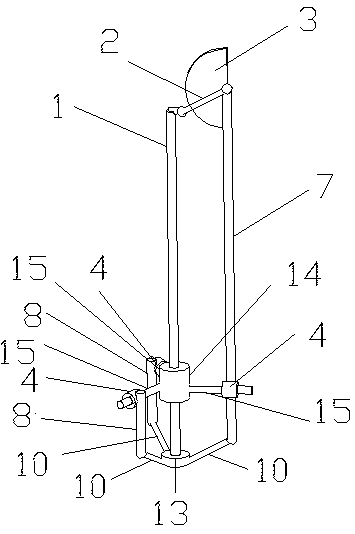

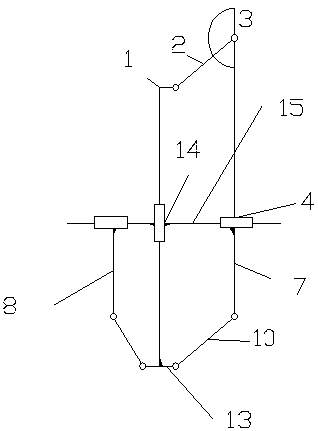

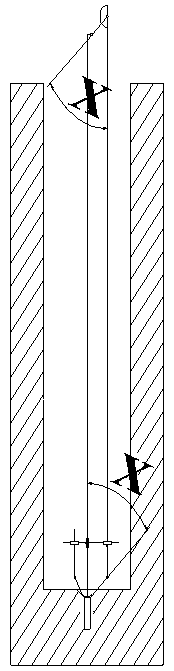

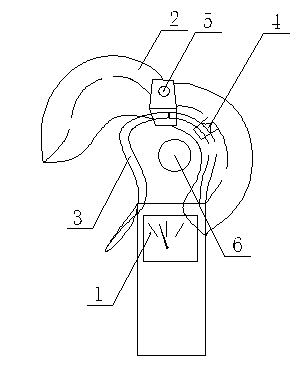

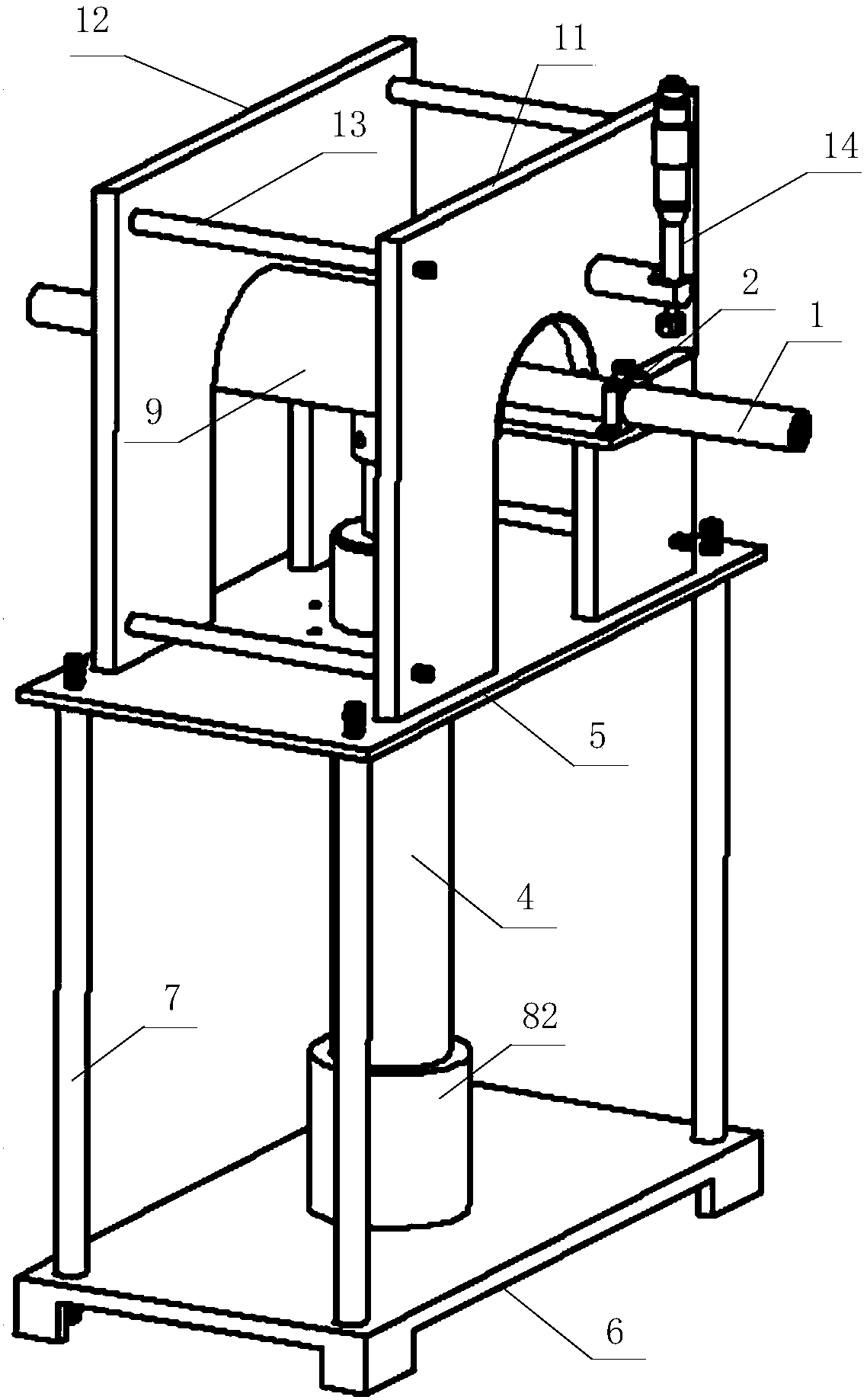

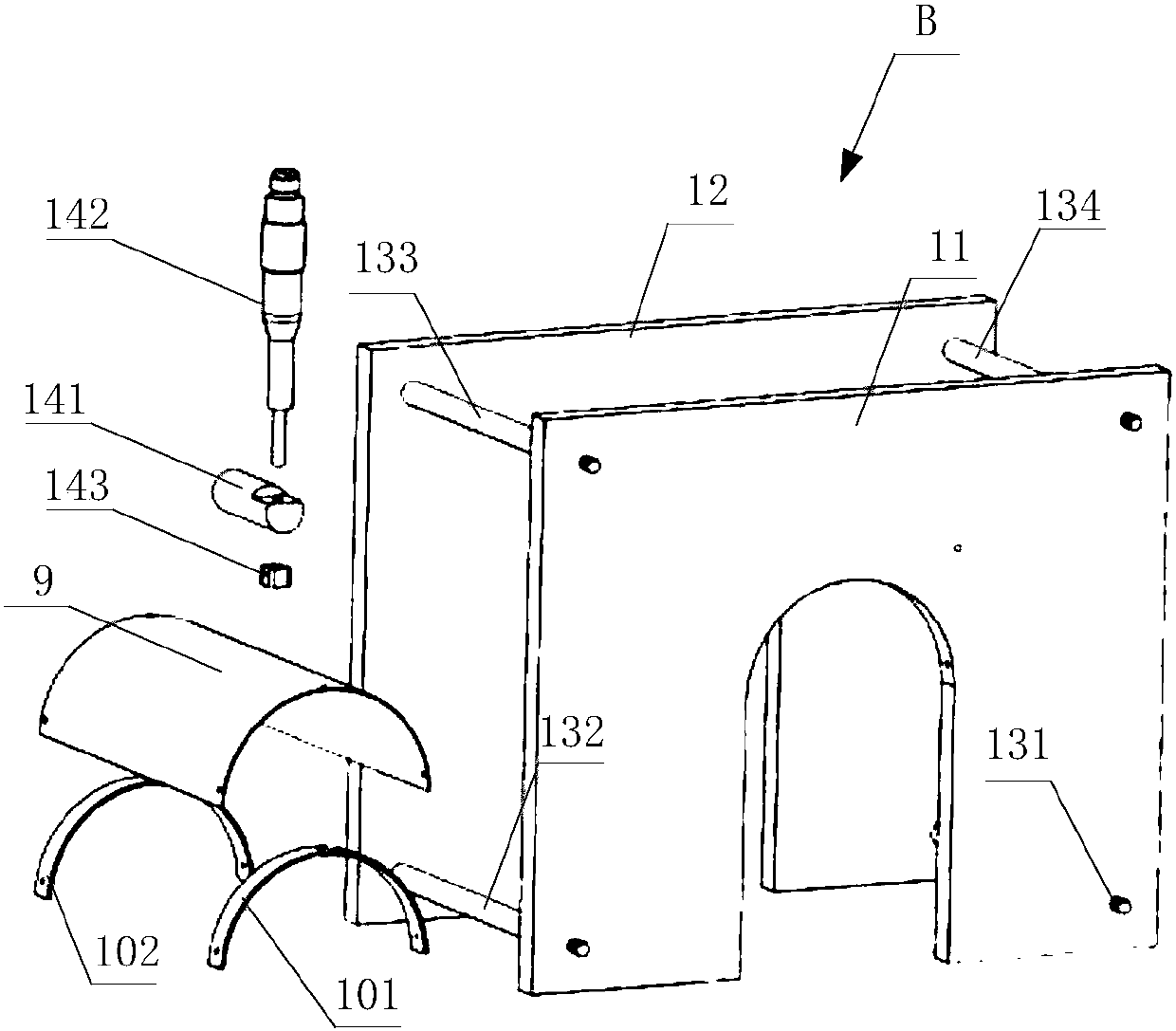

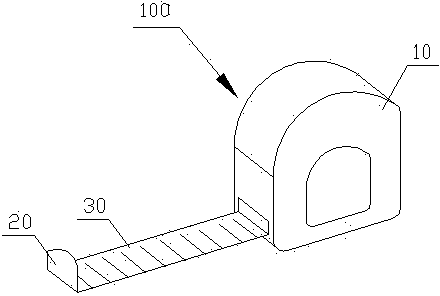

Machine head structure of multifunctional tube-tube full-position automatic TIG welding

ActiveCN108544060AAccurate readoutMeet the actual welding conditionsArc welding apparatusVisual monitoringButt joint

The invention discloses a machine head structure of a multifunctional tube-tube full-position automatic TIG welding. The structure is used for butt joint and lap joint of the tube-tube full-position automatic TIG welding, the structure comprises a visual monitoring mechanism, a welding gun angle adjusting mechanism and a wire feeding posture adjusting mechanism, wherein the welding gun angle adjusting mechanism is arranged on the left side of the visual monitoring mechanism and the wire feeding posture adjusting mechanism is arranged on the right side of the visual monitoring mechanism, and the welding gun angle adjusting mechanism and the wire feeding posture adjusting mechanism are correspondingly connected with the visual monitoring mechanism; the visual monitoring mechanism comprises an arc rail plate, a connecting rod, an electric cross sliding block, a camera box and a lens protection cover; and the welding gun angle adjusting mechanism comprises a mounting frame, a rotating block, a pointer, the arc rail plate and a welding gun; the wire feeding posture adjusting mechanism comprises a wire feeding nozzle, a cross rail, the connecting rod and the arc rail plate. According tothe structure, the machine head structure of the multifunctional tube-tube full-position automatic TIG welding is suitable for the butt joint and the lap joint (inserting and connecting) of the tube-tube full-position automatic TIG welding are carried out, and the form of a root is not limited; the visual monitoring mechanism can clearly observes the condition of molten drop transition, so that the welding parameters, the welding gun angle and the wire feeding posture can be correspondingly adjusted; the optimized structure good in stability, the adjustment is simple, the design is simple andconvenient, and the tube-tube full-position automatic welding can be well realized.

Owner:SOUTH CHINA UNIV OF TECH

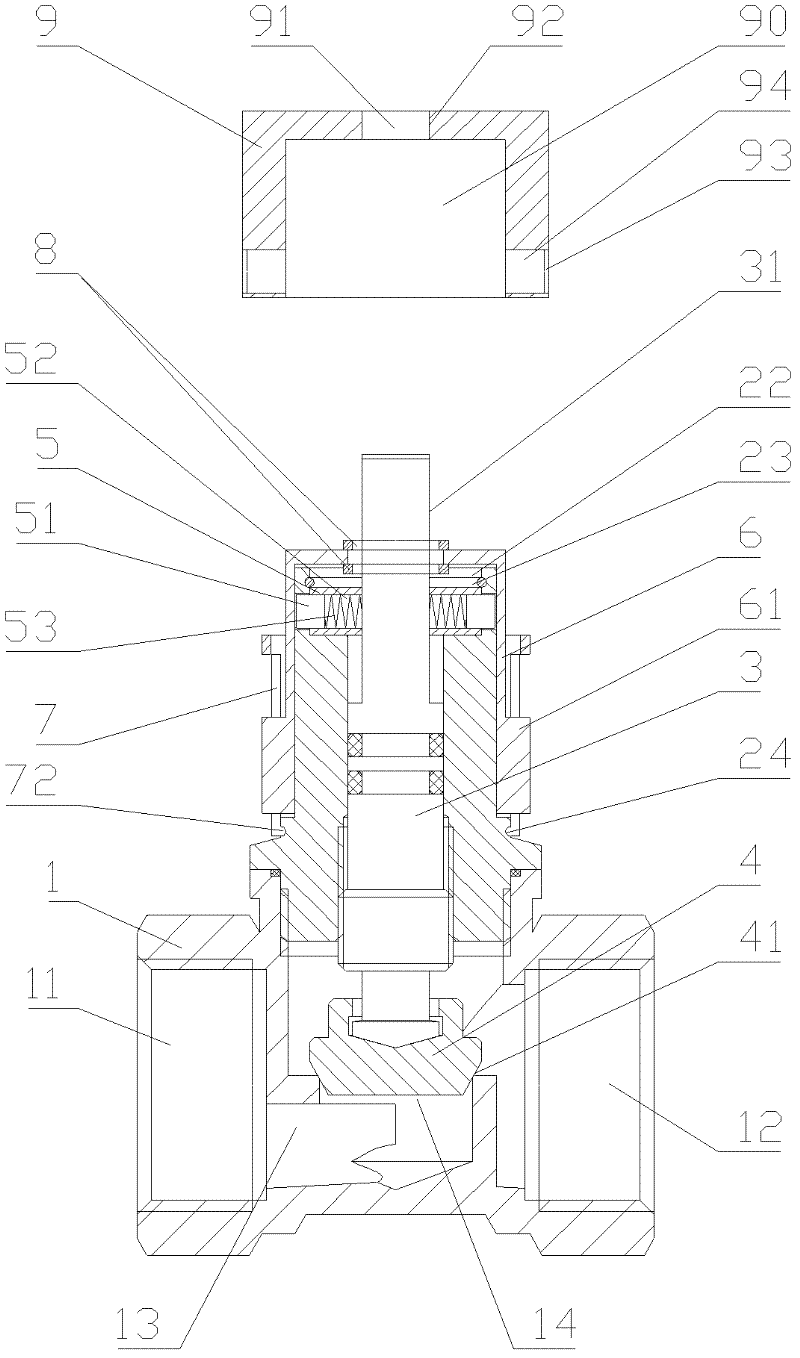

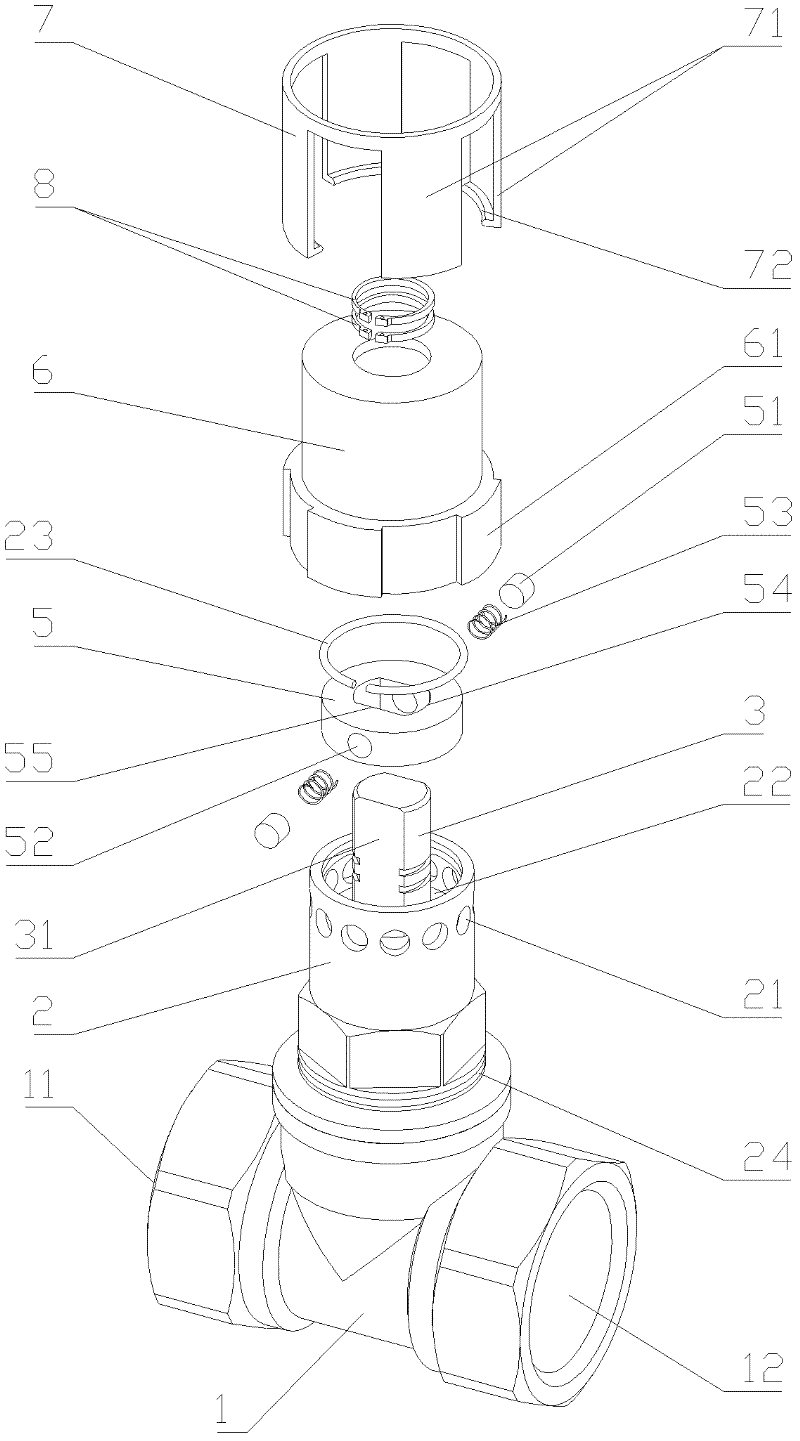

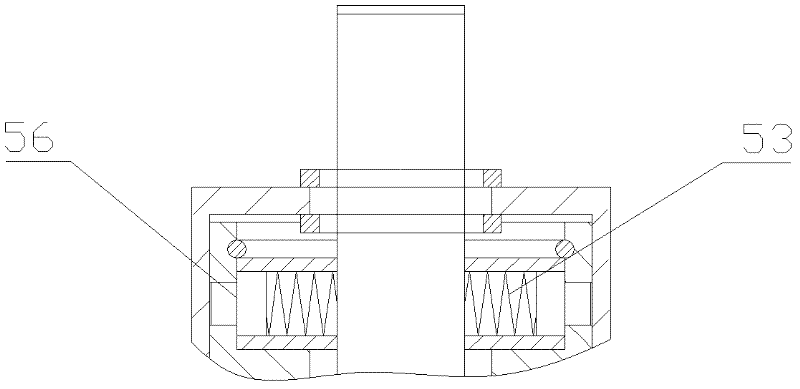

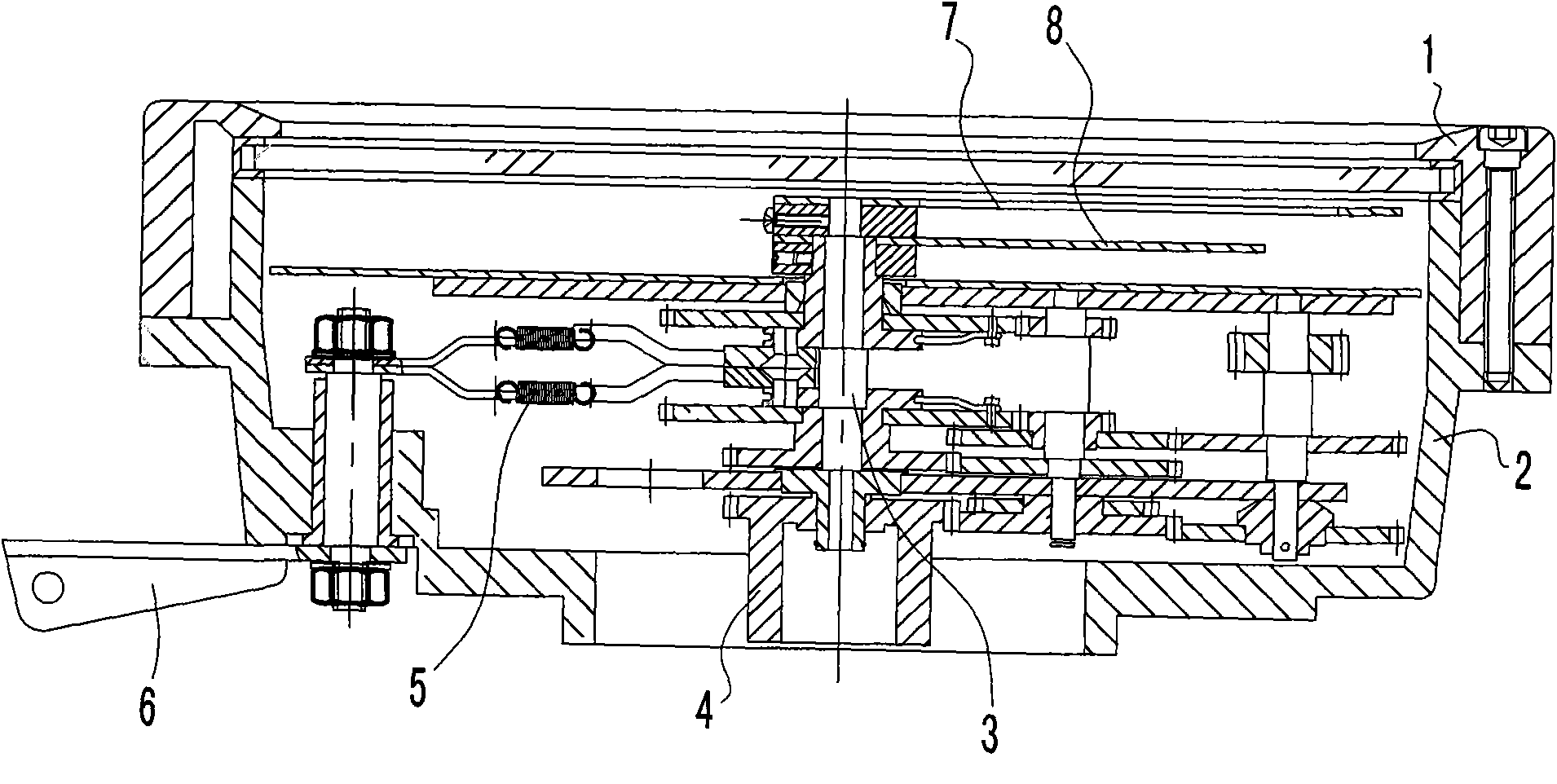

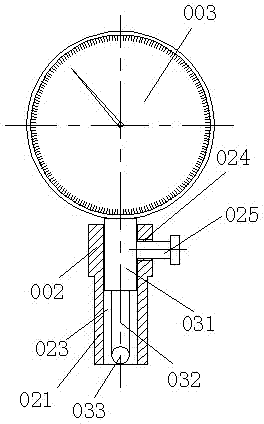

High-precision flow regulating valve with lock

ActiveCN102392910AHigh accuracy of flow regulationAccurate readoutEqualizing valvesSafety valvesEngineeringValve stem

The invention discloses a high-precision flow regulating valve with a lock, which comprises a valve body, a valve cover and a valve stem, wherein two ends of the valve body are respectively provided with an inlet and an outlet, the inlet and the outlet can be communicated through a valve cavity in the valve body, the interior of the valve body is provided with a throttle, the valve cover is tightly connected with the valve body, the valve stem tightly penetrates in the valve cover and can move up and down along the valve cover, the lower end of the valve stem is provided with a valve clack which corresponds to the throttle and can open or close the throttle with the up-and-down movement of the valve stem, the bottom of the valve clack is provided with a tapered ring surface which is matched with the throttle and is provided with a larger diameter on the top and a smaller diameter at the bottom, a lock assembly which can lock the position of the valve stem and can be unlocked by the corresponding key is arranged between the top end of the valve stem and the valve cover, and a flow display component which can display the flow of the throttle in real time is arranged on the valve cover. The high-precision flow regulating valve with a lock provided by the invention has a simple structure, is convenient to manufacture, has linearly flow-regulating and locking functions and can realize high-precision flow regulation.

Owner:ZHEJIANG DUNAN INTELLIGENT CONTROL TECH CO LTD

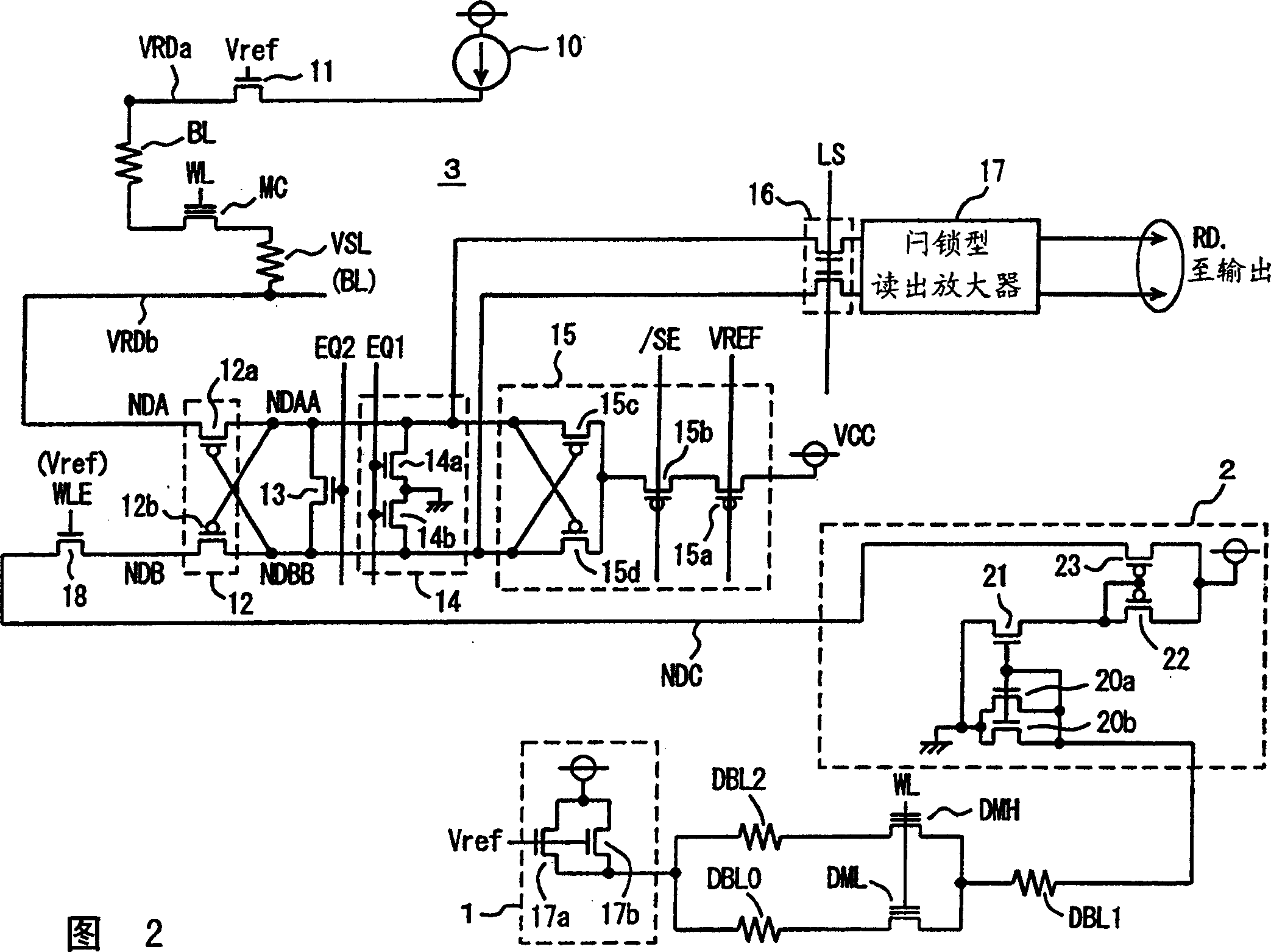

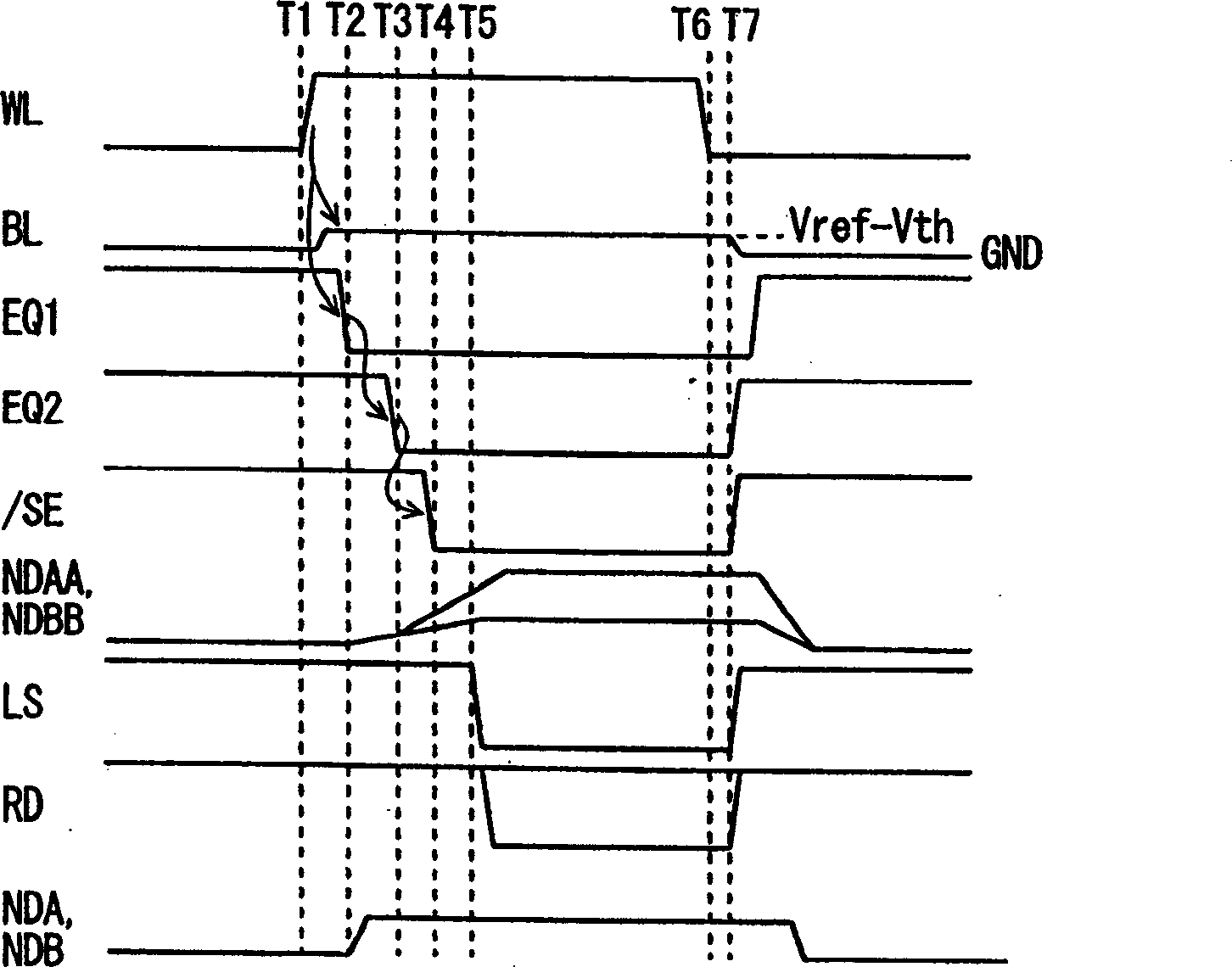

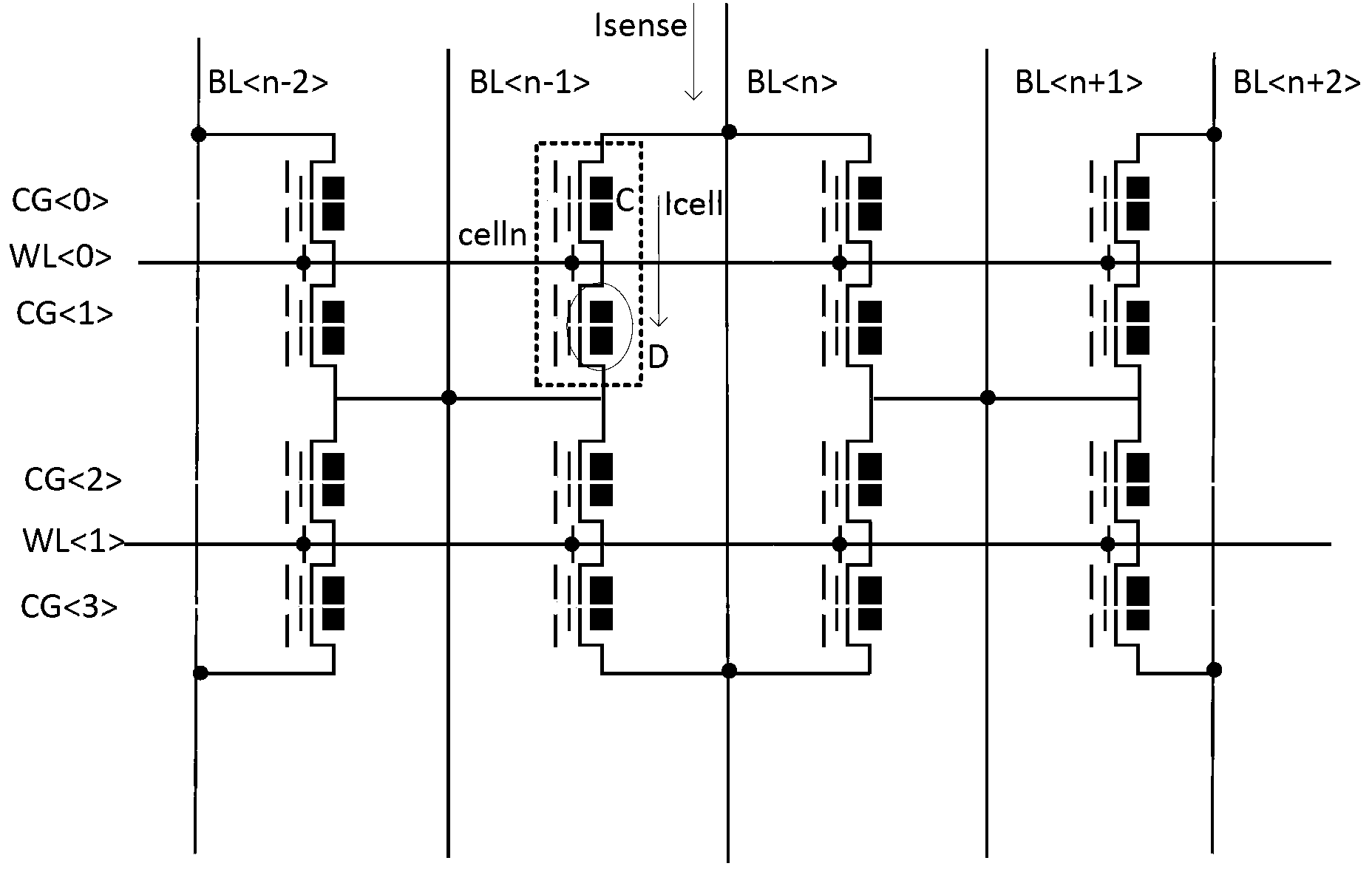

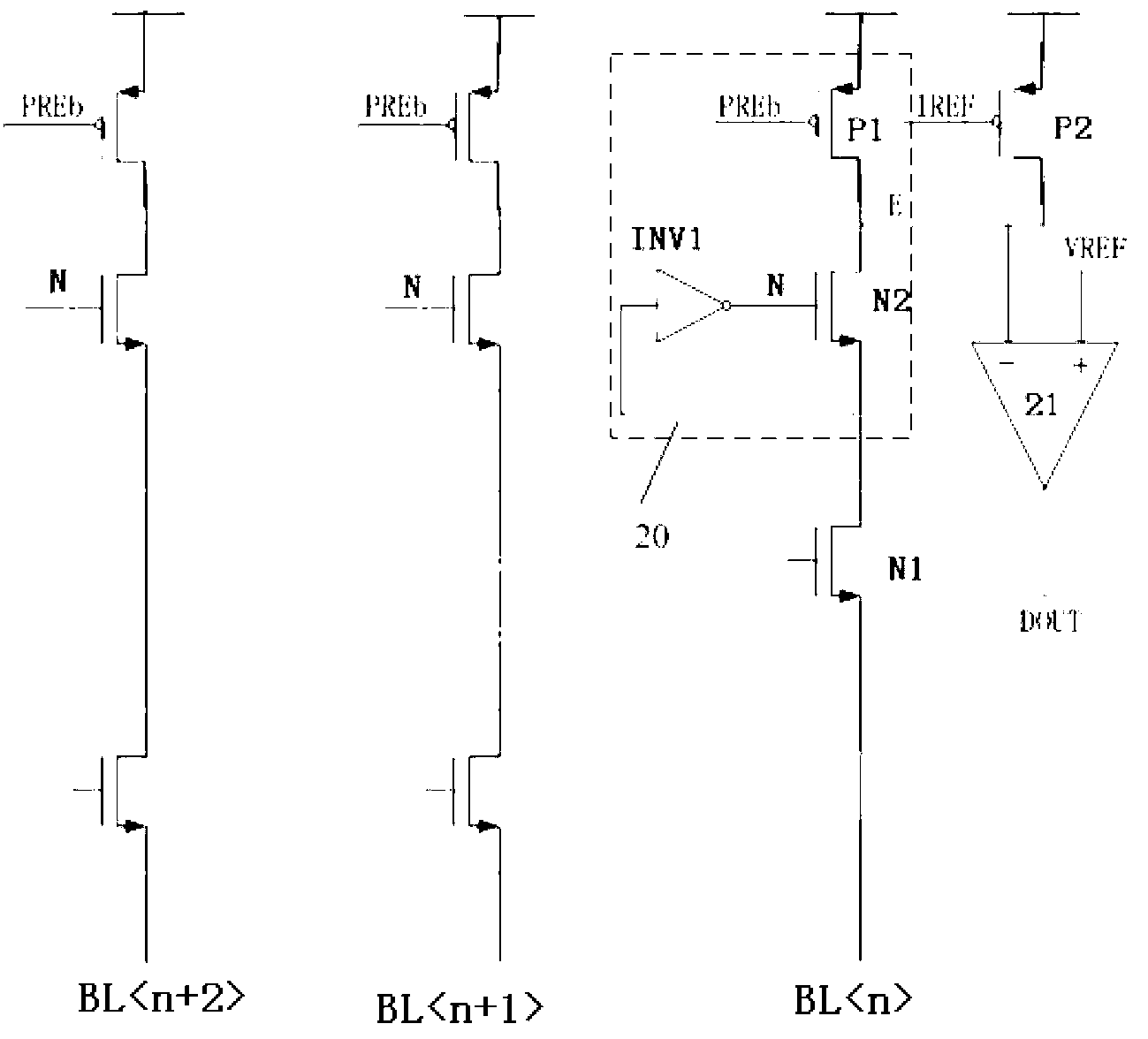

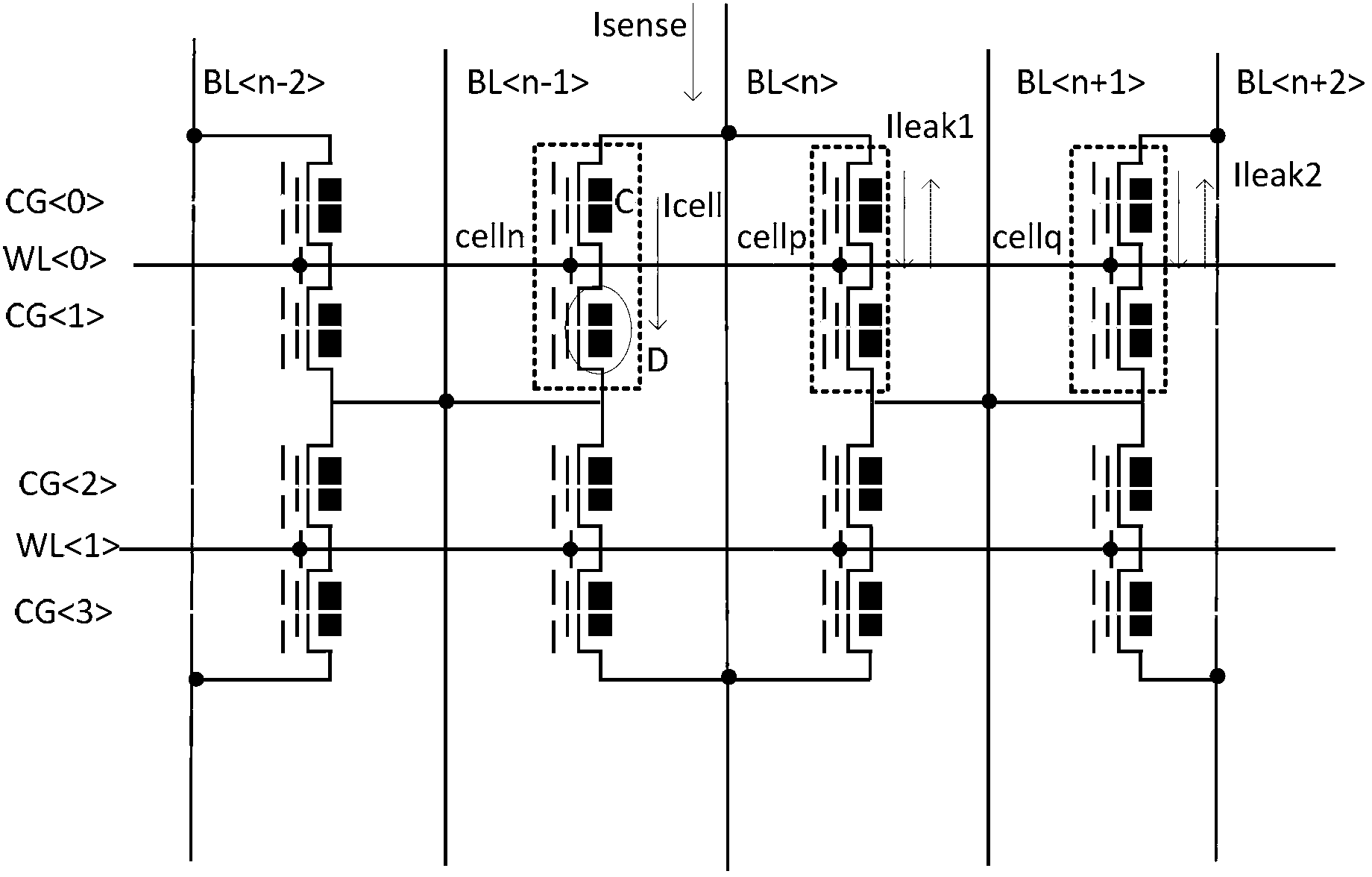

Read-out amplifier

The invention discloses a read-out amplifier, which at least comprises a read-out amplification circuit which is connected to bit lines of a selected storage unit and is used for reading out contents of the selected storage unit in an amplifying manner, a bit line voltage following circuit which is connected between two switching tubes of the read-out amplification circuit, is connected with adjacent bit lines of the bit lines of the selected unit and is used for making input voltage of the bit line voltage of the bit lines be the same in a following manner, and a following circuit pre-charging circuit which is connected to the bit line voltage following circuit and a pre-charging gating signal and is used for performing pre-charging under the control of the pre-charging gating signal. According to the read-out amplifier, the aim of accurately reading out stored values of the selected unit at high speed can be fulfilled.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

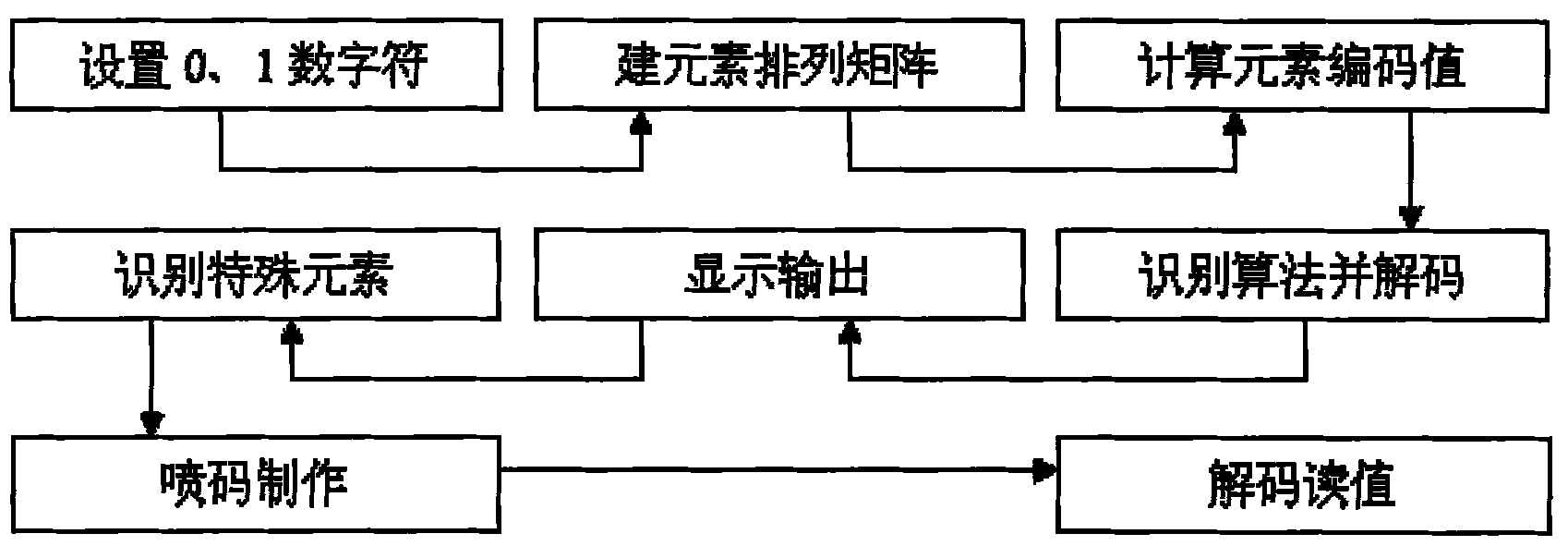

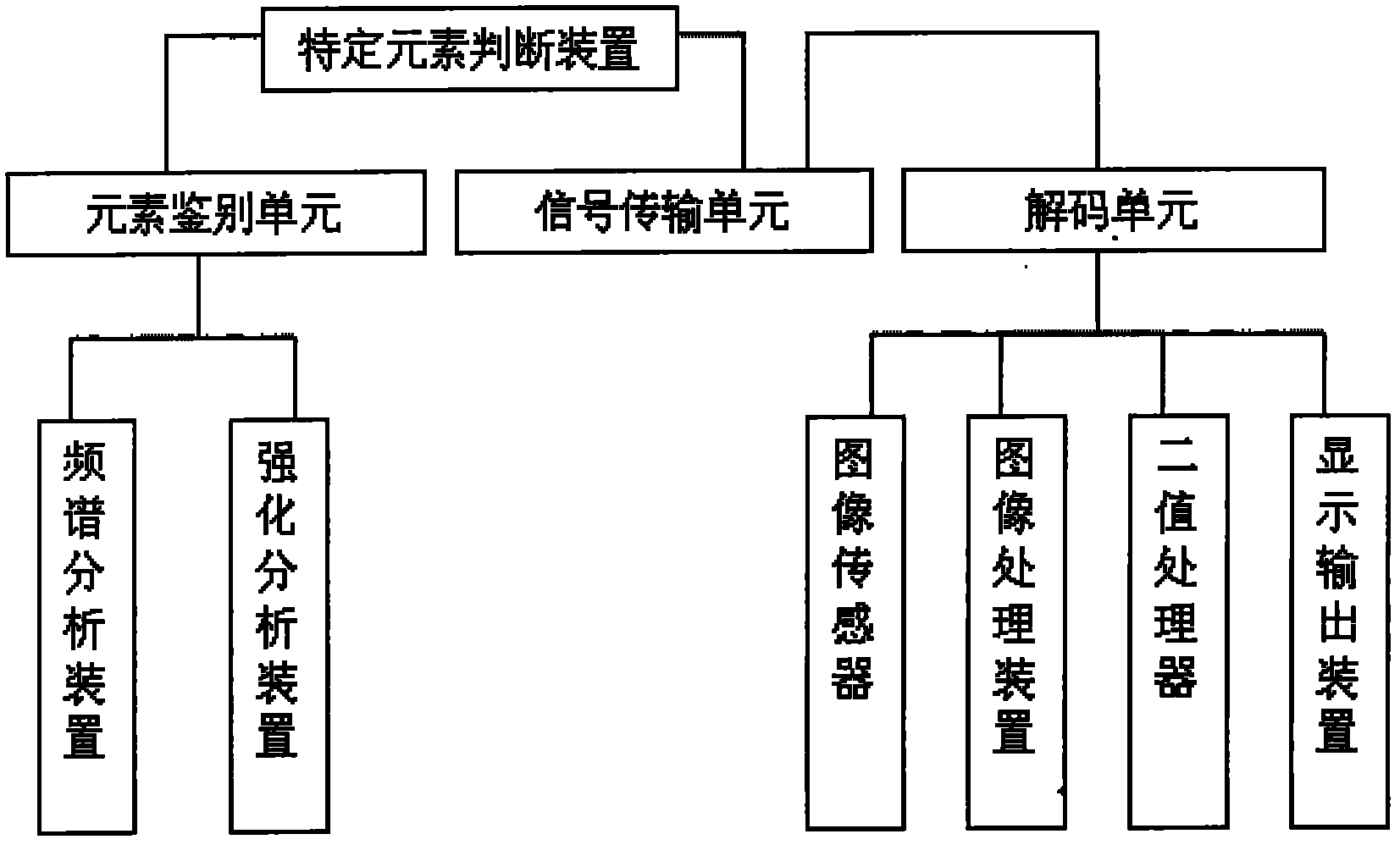

Anti-counterfeiting coding method and decoding device

InactiveCN102073893AFast readoutAccurate readoutRecord carriers used with machinesSensing by electromagnetic radiationComputerized systemComputer engineering

The invention discloses an anti-counterfeiting coding method. The method comprises the following steps of: (1) setting a coding device for generating an anti-counterfeiting graph, and performing coding through the coding device by using the existence state of element points printed by using a special invisible material and position information thereof in an anti-counterfeiting graph array as coding information factors; (2) inputting coding condition data through a computer system connected with the coding device, automatically performing calculation according to the set conditions and the coding rules through a coder to obtain the numerical values of element codes, and automatically generating anti-counterfeiting audio or images according to the numerical values; and (3) outputting the generated anti-counterfeiting audio or images. The invention also provides a decoding device for implementing the method. When special elements are detected, the numerical values of the codes are calculated according to the arrangement of the element points, and the purpose of management is further fulfilled.

Owner:陆宝武

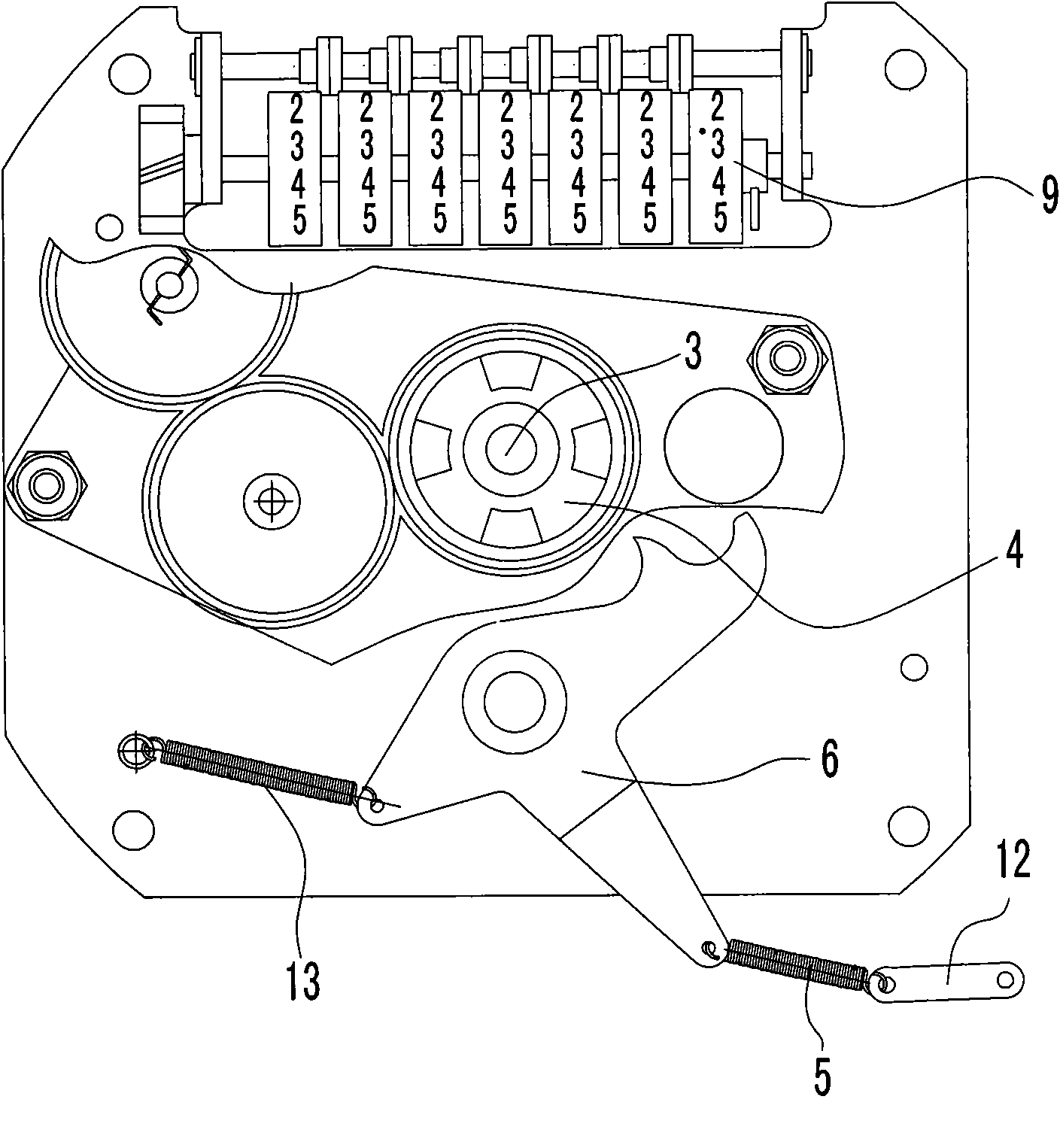

Zeroing counter for volumetric flowmeter

The invention discloses a zeroing counter for a volumetric flowmeter. The zeroing counter is characterized by comprising a dual-pointer single-flow metering unit consisting of a minute hand and a hour hand, a total accumulation metering unit formed by a print wheel group, a four-jaw wheel gear connected with the transmission shaft of a flowmeter governor and a zeroing operation mechanism. The invention is the zeroing counter for the volume type flow meter which has convenient, quick and accurate counting without calculation, can directly acquire online continuous metering values and single metering values.

Owner:HEFEI JINGDA INSTR

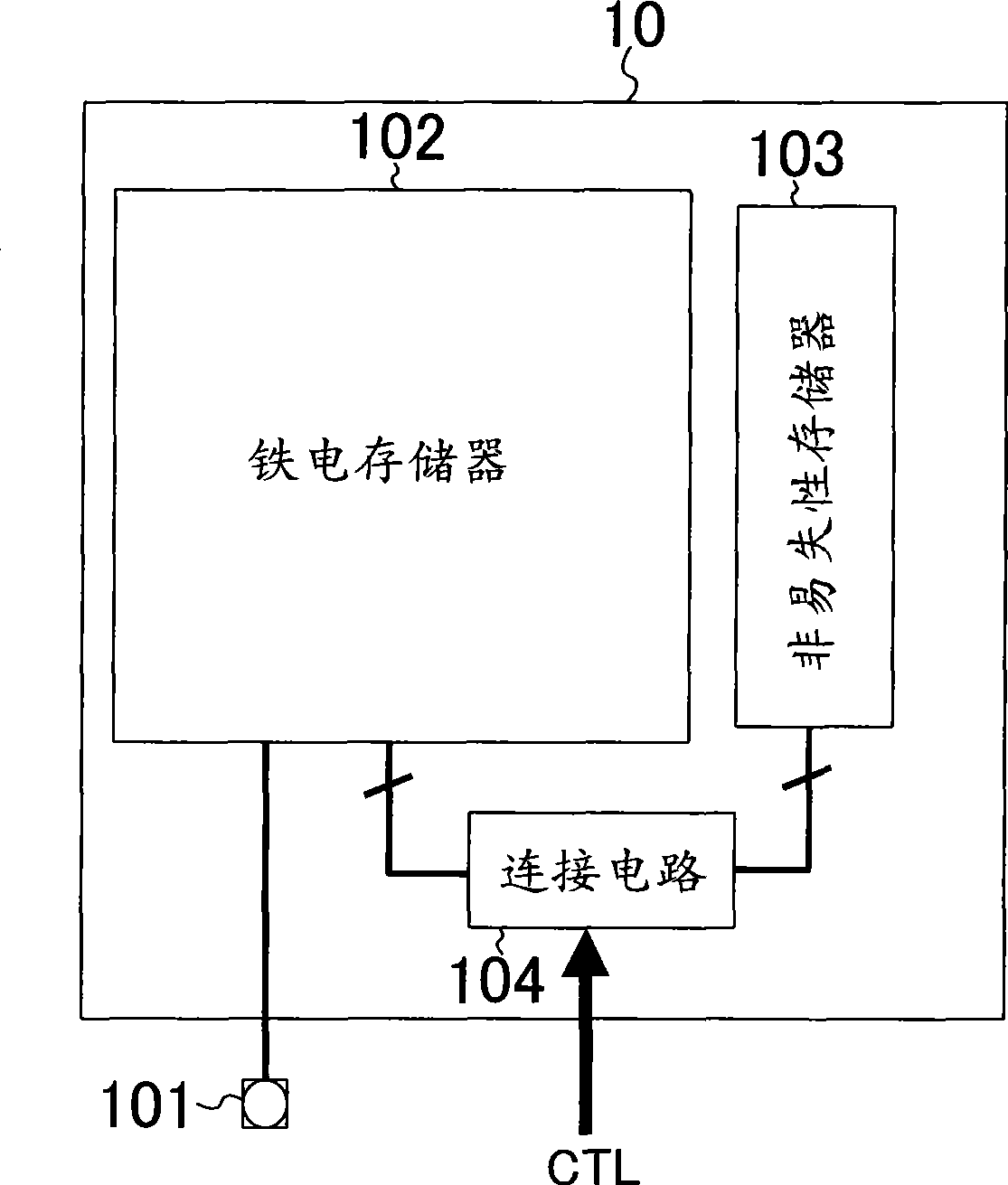

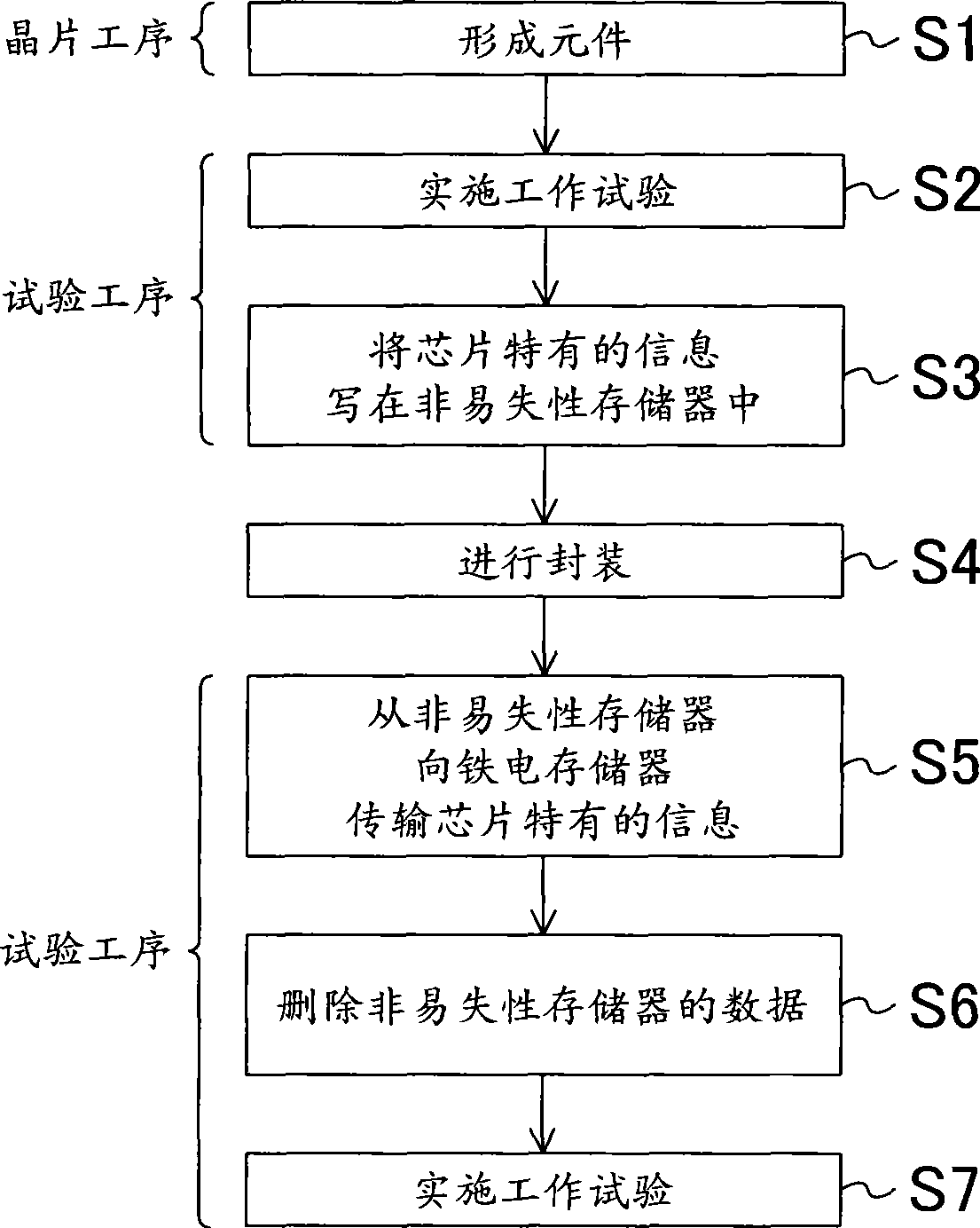

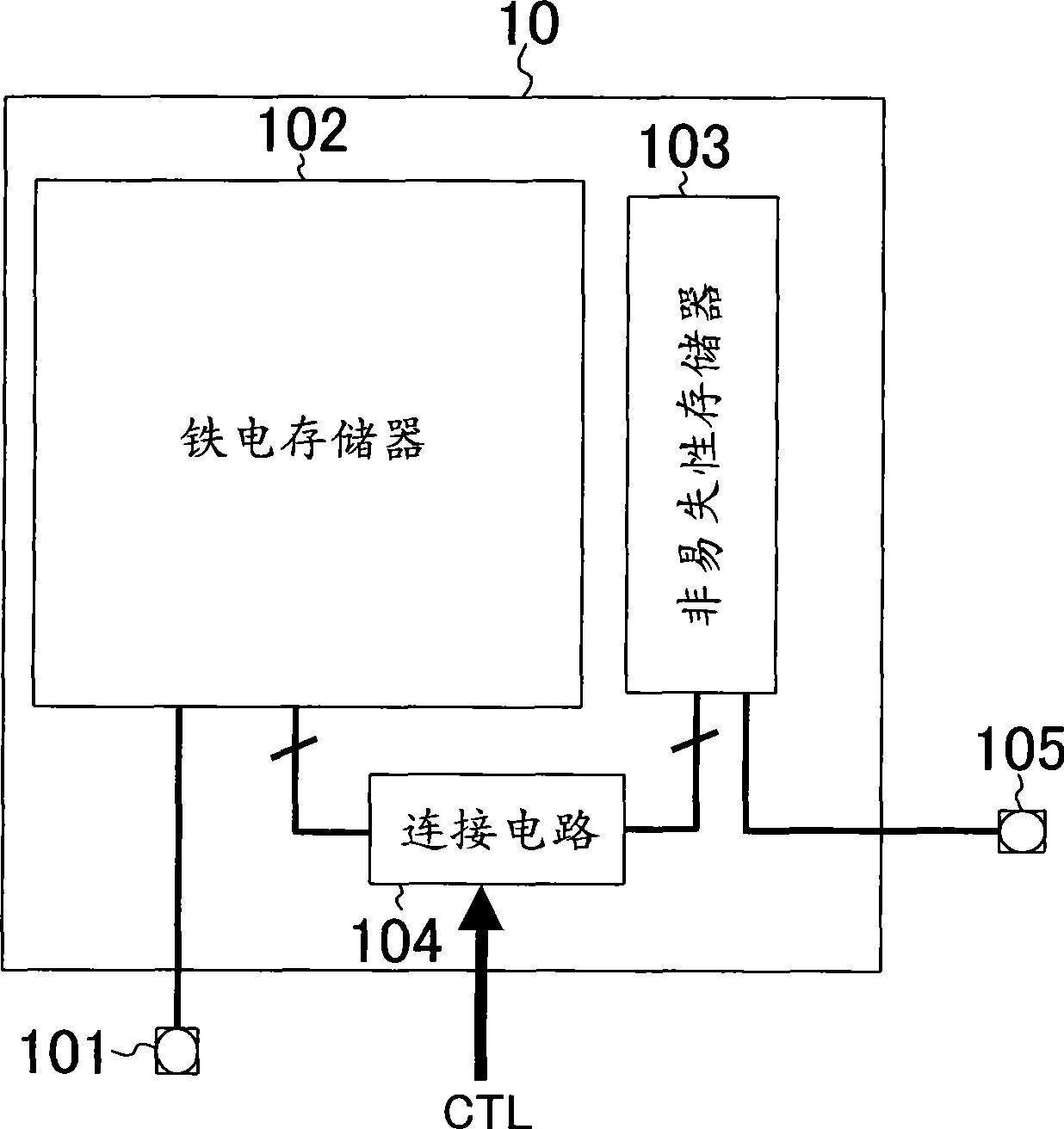

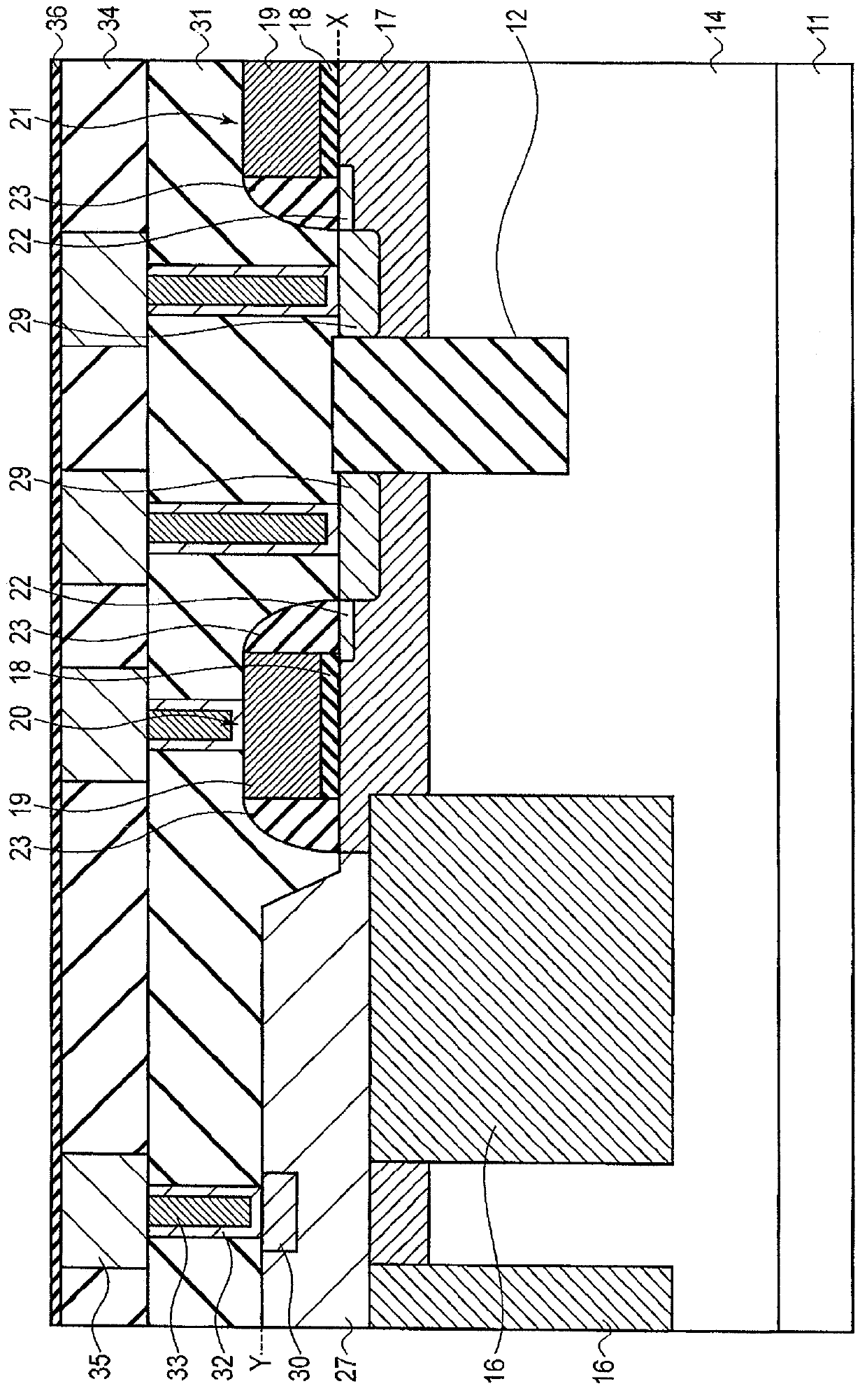

Semiconductor memory device and method for fabricating the same

InactiveCN101483063AAccurate readoutSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductorData retention

The present invention discloses a semiconductor memory device and a method for fabricating the same. The semiconductor memory device (10) including a ferroelectric memory (102) includes: a nonvolatile memory (103) having higher data retention capability under high temperature than the ferroelectric memory (102); and a connection circuit (104) for switching between connection and disconnection of the ferroelectric memory and the nonvolatile memory (103). The ferroelectric memory (102) receives, through the connection circuit (104), at least part of data which is unique to the device and which has been written into the nonvolatile memory (103), and retains the received data. Conventionally loss of the data written into a ferroelectric memory may be prevented due to heat treatment in process of fabricating the ferroelectric memory.

Owner:PANASONIC CORP

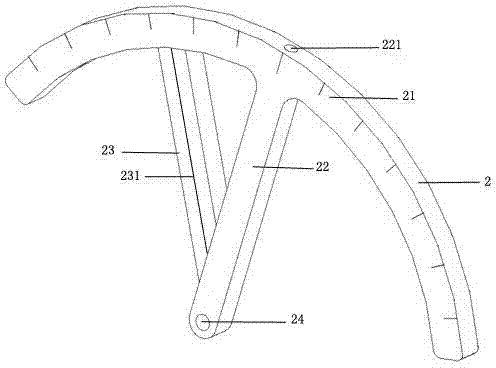

Rotary osteotomy bone cutting device and application thereof

The invention relates to a rotary osteotomy device. The rotary osteotomy device comprises a steel needle positioner and a protractor, wherein a steel needle positioning column is arranged on the front end of the steel needle positioner, a steel needle tunnel is formed in the middle of the steel needle positioning column, a cross rod is arranged on the tail end of a handle of the steel needle positioner, a sawtooth-shaped groove is formed in the cross rod, the protractor is in a T shape and is provided with a scale, a fixed handle and a movable handle, the scale is in an arc shape, and the lower end of the movable handle is connected with the bottom of the fixed handle through a rotating shaft. According to the rotary osteotomy device, by using the steel needle positioner, two kirschner wires can be vertically drove into bones, and good parallelism is kept; a through hole is formed in the fixed handle of the protractor, so that the kirschner wires can be sleeved; a rotation angle can be quickly and accurately read by swinging the movable handle; the orthomorphia accuracy is obviously increased, the orthomorphia time is shortened, hemorrhage during orthomorphia is reduced, and orthomorphia wounds are reduced.

Owner:SHANGHAI CHILDRENS MEDICAL CENT AFFILIATED TO SHANGHAI JIAOTONG UNIV SCHOOL OF MEDICINE

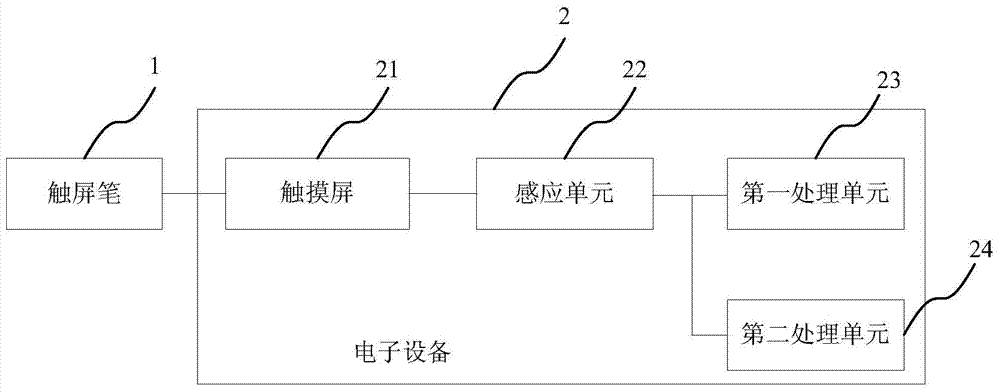

Electronic device set comprising touch screen pen and electronic device

InactiveCN103760994AIncrease flexibilityAccurate readoutDigital data processing detailsInput/output processes for data processingEngineeringElectrical and Electronics engineering

The invention provides an electronic device set comprising a touch screen pen and an electronic device. According to the electronic device set, the touch screen pen comprises a penholder, a plurality of contacts and second contacts; the plurality of contacts are positioned at the bottom end of the penholder and arranged in the same plane; second contacts are positioned at the bottom end of the penholder and are higher than the plane of the first contacts; an elastic part, connected with the second contacts, comprises a handheld part and an elastic part; the handhold part is arranged on the penholder; and the elastic part is connected with the handheld part and the second contacts. The electronic device comprises a touch screen, a sensing unit, a first processing unit and a second processing unit, wherein the sensing unit is connected with the touch screen; the first processing unit is used for detecting first track coordinate subsequences comprising a plurality of contacts in a track coordinate sequence which is output by the sensing unit and reading information in a region which is encircled by the first track coordinate subsequences; and the second processing unit is used for detecting a second track coordinate subsequence comprising a single contact in the track coordinate sequence which is output by the sensing unit and generating an operation instruction for the second track coordinate subsequence.

Owner:HUAQIN TECH CO LTD

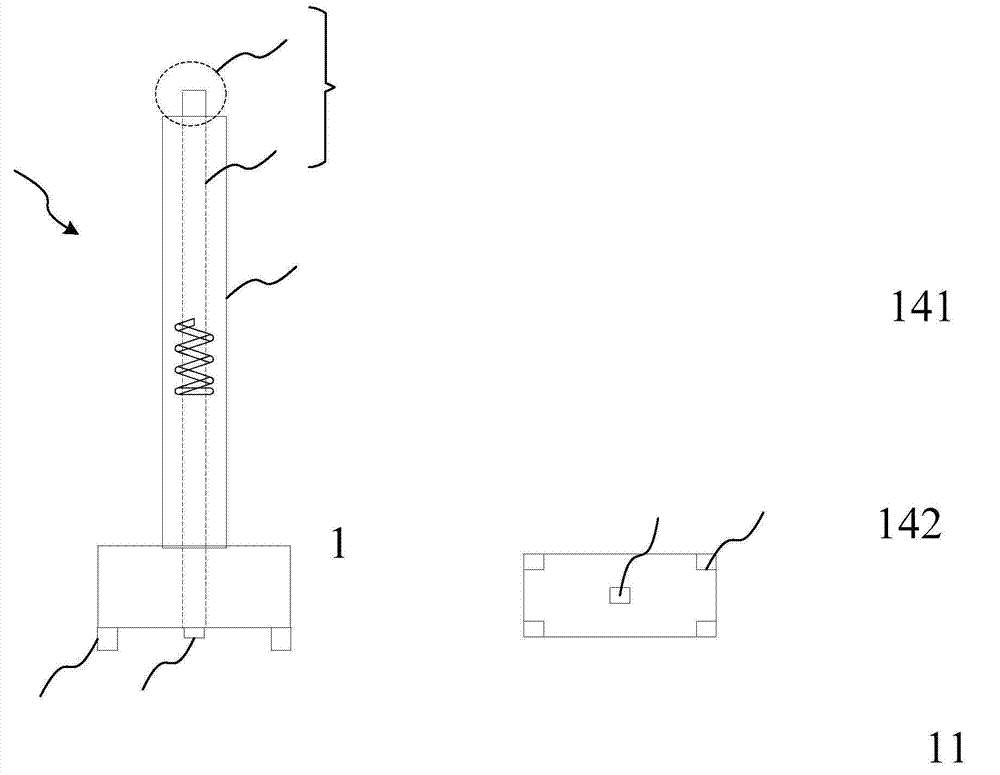

Automatic rotation test tube bar code recognition device and full-automatic sample treatment system

PendingCN114091496APrevent looseningAccurate readoutCo-operative working arrangementsSensing by electromagnetic radiationDrive wheelControl engineering

The invention provides an automatic rotation test tube bar code recognition device, and when a first detection device detects that a sample support is in a rotary code scanning position, a controller controls a second driving device to start. And when the second detection device detects that the sample support is in a clamping state, the controller controls the first driving device to start. A first driving device drives a driving wheel module to rotate, the driving wheel module drives a sample support (with a test tube) to rotate, an idle wheel module and a driven idle wheel module passively rotate under the action of friction force of the test tube, and a code scanner carries out bar code recognition on the rotating sample support (with the test tube). In order to ensure the pressing force of friction wheels on the driving wheel module, the idle wheel module and the driven idle wheel module on the sample support, a second driving device is used for controlling the spring pressing force of a spring device, so that the friction wheels are always tightly attached to the sample support when rotating, the sample support is prevented from loosening, and the test tube bar code is accurately read. The invention further provides a full-automatic sample processing system.

Owner:AUTOBIO LABTEC INSTR CO LTD

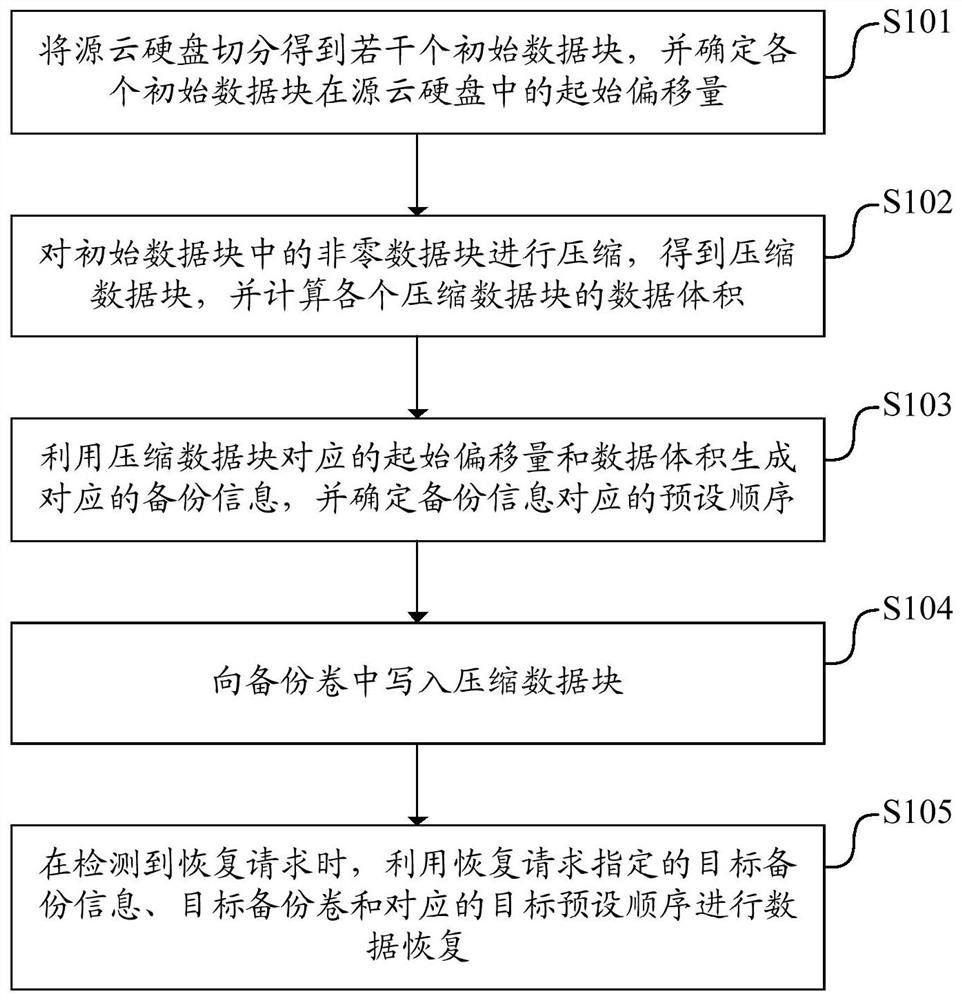

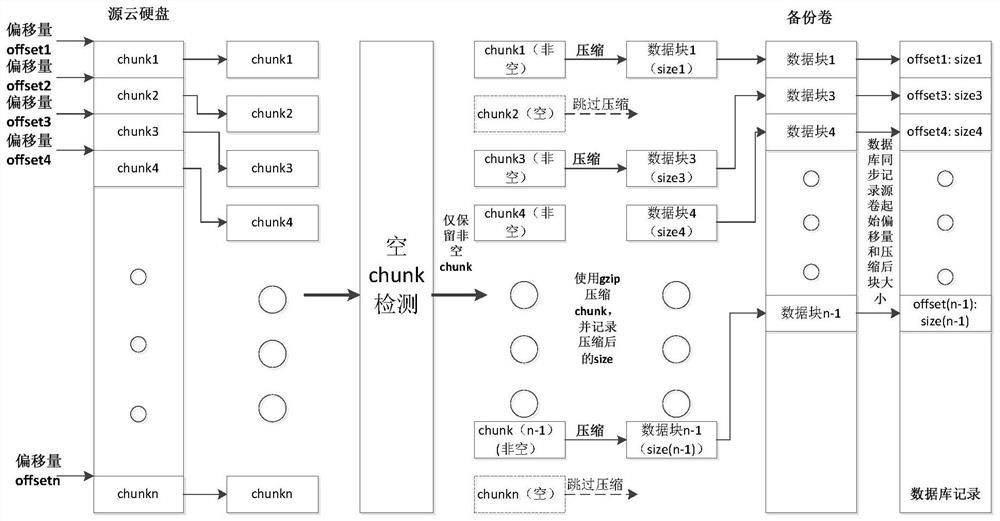

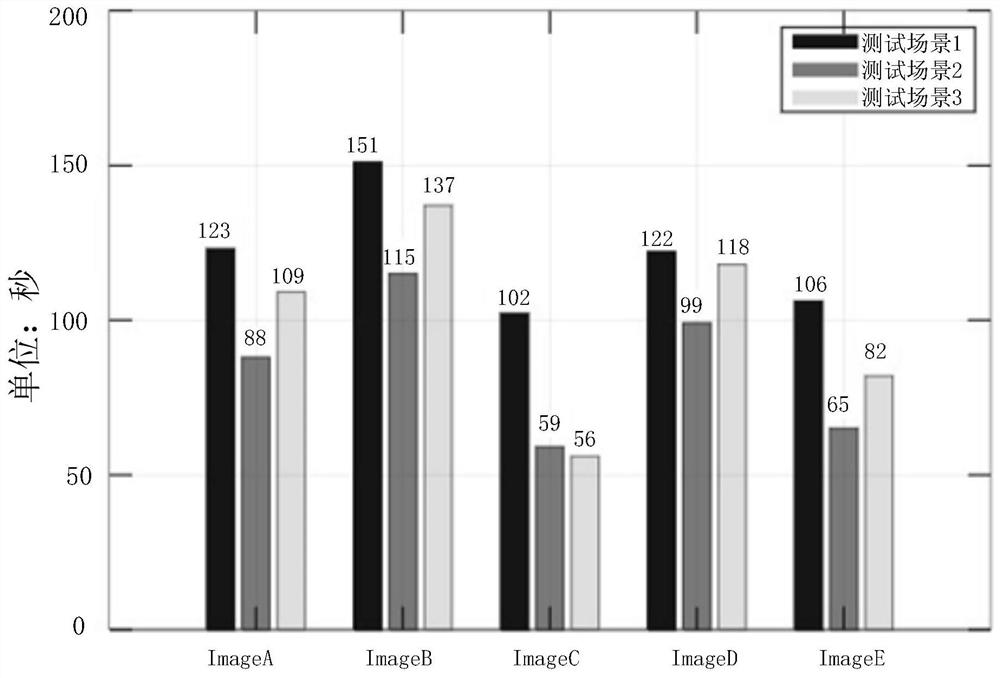

Cloud hard disk data compression backup and recovery method and device, equipment and storage medium

ActiveCN113722150AAccurate readoutImprove utilization efficiencyEnergy efficient computingRedundant operation error correctionData compressionEngineering

The invention discloses a cloud hard disk data compression backup and recovery method and device, electronic equipment and a computer readable storage medium, and the method comprises the steps: segmenting a source cloud hard disk to obtain a plurality of initial data blocks, and determining the initial offset of each initial data block in the source cloud hard disk; compressing non-zero data blocks in the initial data blocks to obtain compressed data blocks, and calculating the data volume of each compressed data block; generating corresponding backup information by using the initial offset and the data volume corresponding to the compressed data block, and determining a preset sequence corresponding to the backup information; writing the compressed data block into the backup volume; and when a recovery request is detected, performing data recovery by using target backup information specified by the recovery request and a corresponding target preset sequence. According to the method, the occupation amount of the storage space can be reduced on the premise of ensuring correct data recovery.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

Tool for measuring angle of tapered hole at bottom of deep groove cavity

The invention belongs to the technical field of measuring tools, in particular to an instrument for rapidly measuring the angle of a tapered hole at the bottom of a deep groove cavity. The instrumentcomprises a central rod, wherein the top of the central rod is connected with one end of a connecting rod, and the other end of the connecting rod is connected with a protractor; the protractor is arranged on an auxiliary measuring rod; a vertical sliding connecting block is arranged at the lower part of the central rod; a vertical sliding connecting block is connected with the three transverse rods, wherein one transverse rod is connected with the auxiliary measuring rod through a transverse sliding connecting block, and the other two transverse rods are respectively connected with a stop endconnecting rod through transverse sliding connecting blocks; the bottom of the central rod is connected with a stop end cylinder, and the stop end cylinder is connected with the two stop end connecting rods and the auxiliary measuring rod through stop end measuring rods. The instrument is simple in structure and easy to operate, can go deep into the bottom of the deep groove cavity, can accurately and rapidly read the specific numerical value of the angle of a tapered hole, and can provide practical data for later processing condition analysis.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

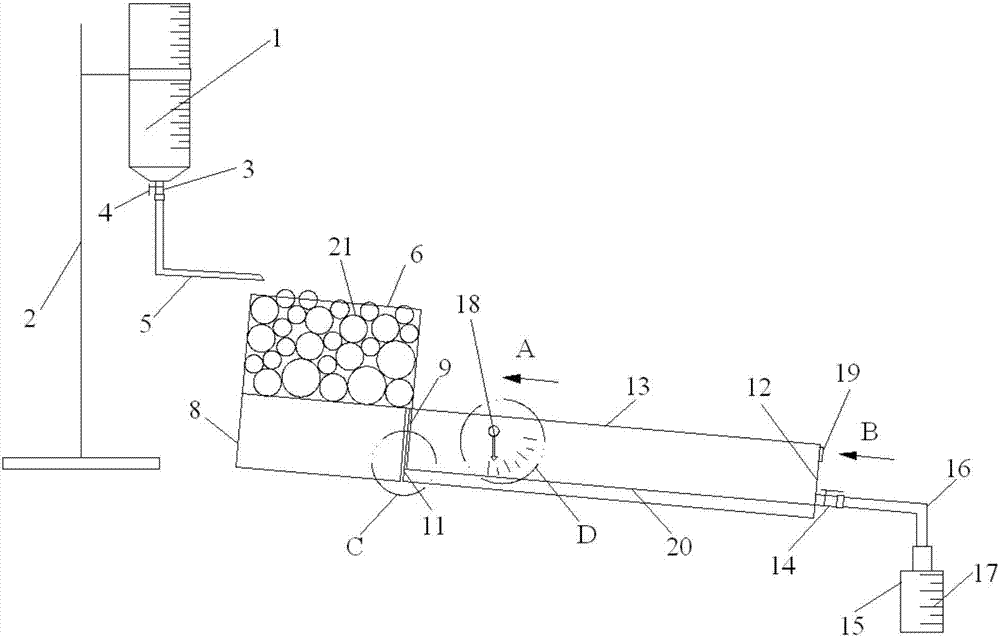

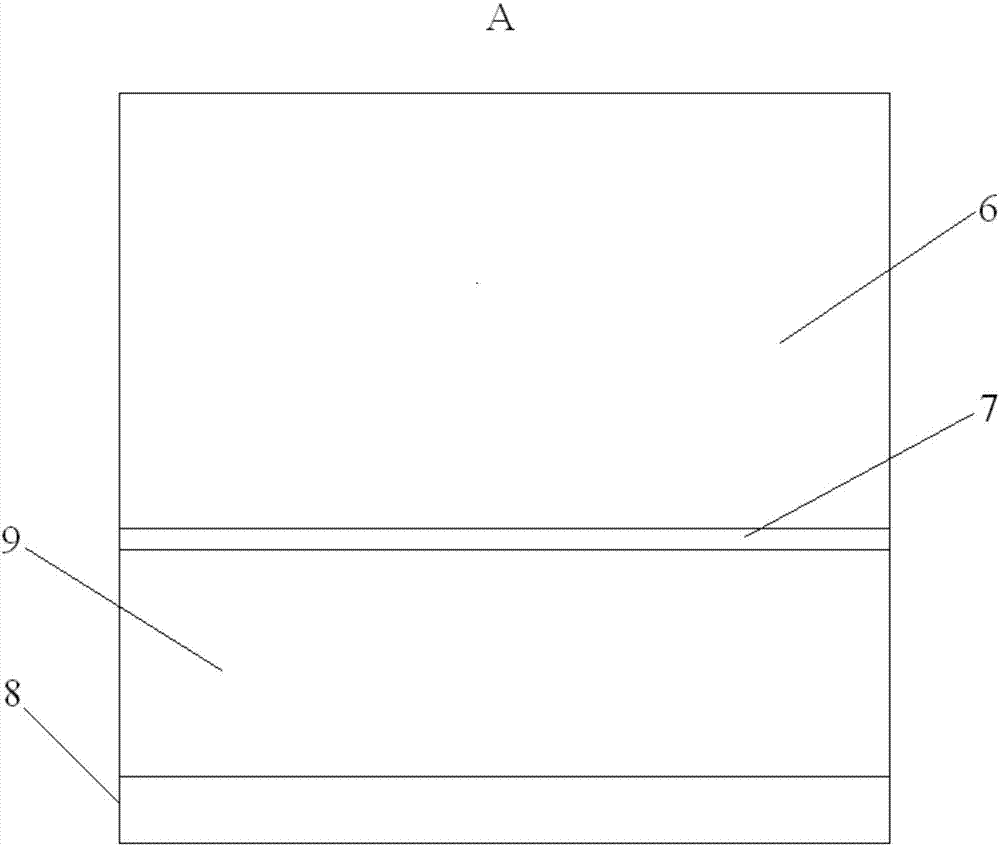

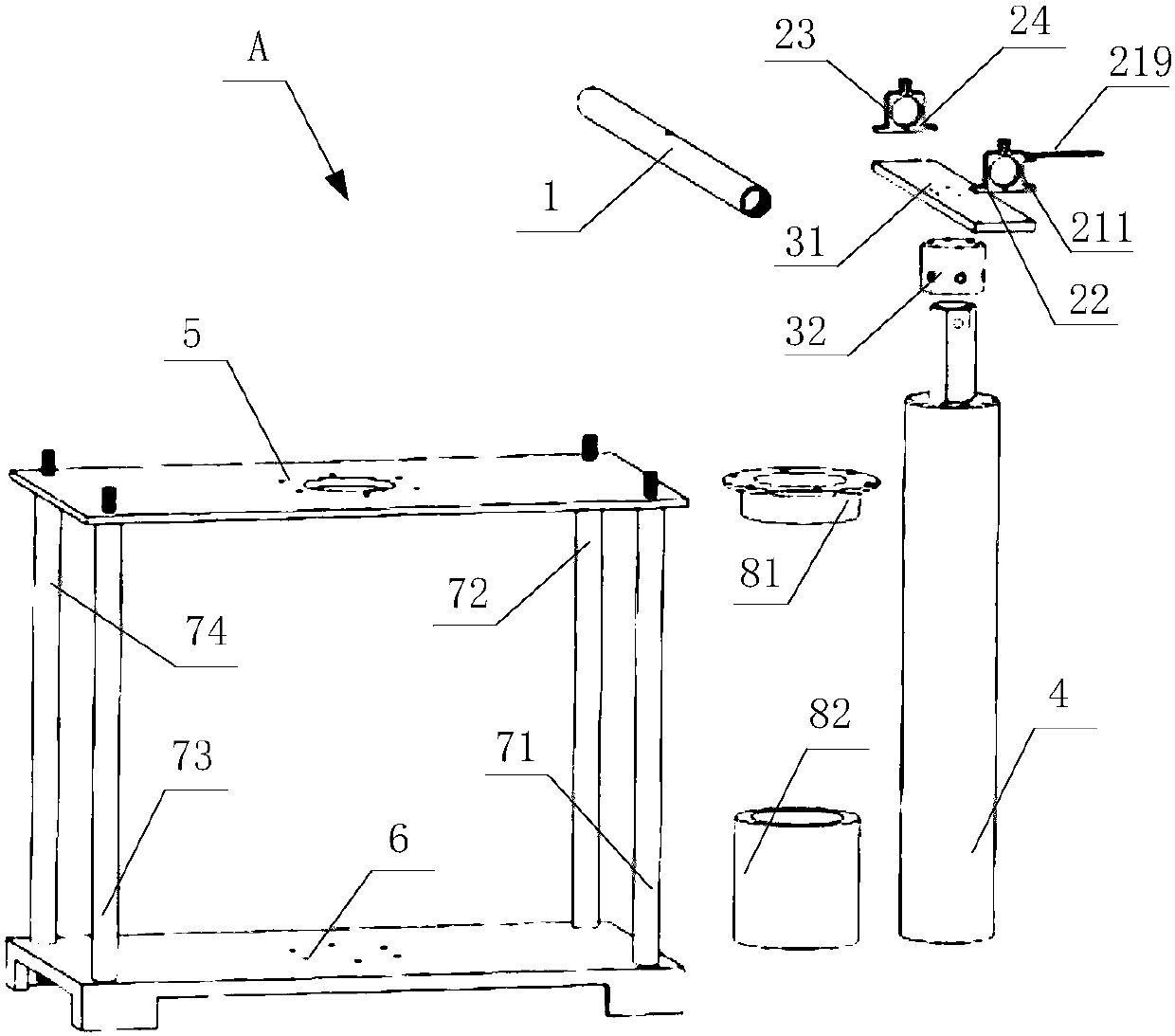

Portable surface runoff simulating and measuring device

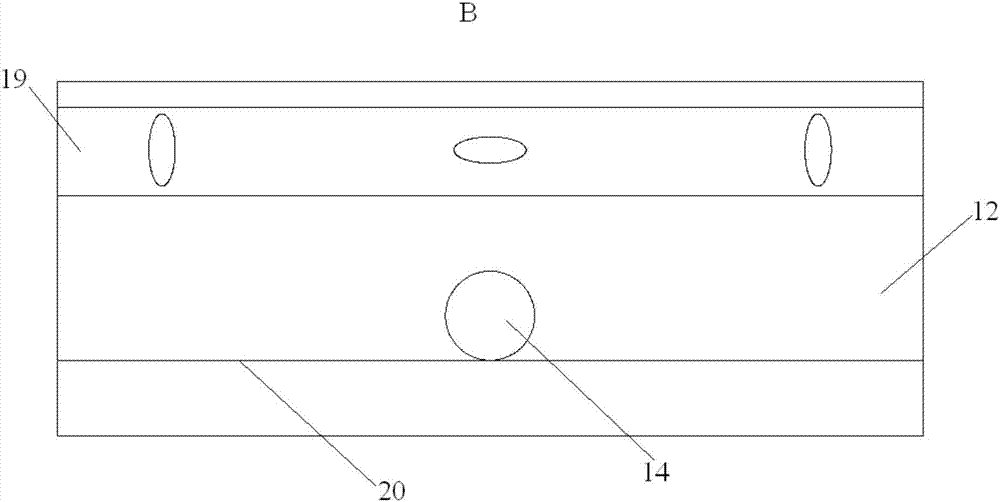

ActiveCN107255702APrevent splashRapid determinationEarth material testingGraduated cylinderObservation data

The invention discloses a portable surface runoff simulating and measuring device. The device comprises a measuring cylinder, a water diversion channel, a runoff frame and a sampling bottle, wherein the measuring cylinder is fixed on a bracket; a water outlet and a valve are arranged at the lower end of the measuring cylinder; the water outlet is communicated with the water diversion channel through a water delivery pipe; a water outlet slot hole is laterally formed in the side wall of the water diversion channel; a supporting seat and an access board are arranged below the water diversion channel; the runoff frame comprises a front inserting plate, a rear inserting plate and two side inserting plates which are connected with one another and form a rectangle; the access board is buckled on the inner side of the front inserting plate through an inserting slit; a runoff output connector is arranged in the outer side of the rear inserting plate; the sampling bottle is communicated with the runoff output connector on the rear inserting plate through a runoff output pipe; a volume scale line is arranged on the side wall of the sampling bottle; a vertical angle measuring device is arranged on the outer side wall of each side inserting plate; a horizontal reference device is arranged on the outer side wall of the rear inserting plate. The simulating and measuring device is centimetre-level in dimension, can repeatedly measuring surface runoff sample data in quantity, and improves the accuracy of observation data.

Owner:CHANGAN UNIV

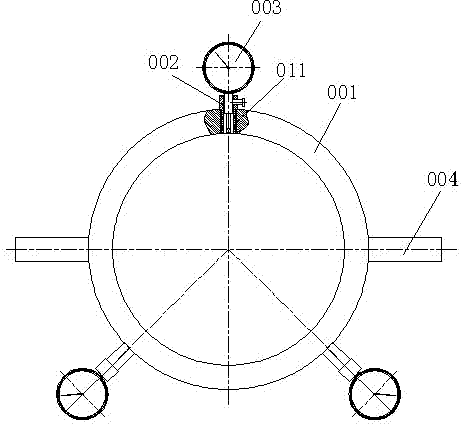

Journal roundness tester

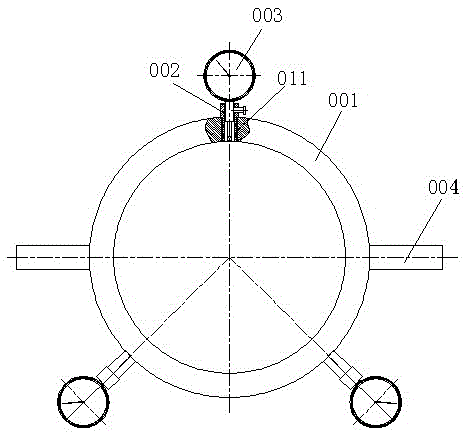

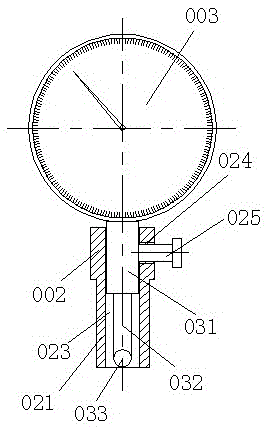

ActiveCN103808239BAccurate readoutRealize accurate and quantitative measurementMechanical counters/curvatures measurementsEngineeringScrew thread

The invention discloses a shaft neck roundness tester. The shaft neck roundness tester comprises a testing circular ring, three dial indicator supports arranged into trisection around an axis of testing circular ring, dial indicators arranged in the dial indicator supports and a raised handle arranged on the external surface of the testing circular ring, wherein the dial indicator supports are in shaft sleeve shapes, a connection part at the bottom of the tester is connected with a through hole which is formed in the external surface of the testing circular ring, and the external surface of the testing circular ring is exposed at the upper end of the tester and a threaded hole which is connected with an inner hole is formed in a side wall of the tester; a bolt is internally screwed in the threaded hole, sleeves at the bottom of the dial indicators are stretched into the inner holes of the dial indicator supports, measuring heads which are located at the ends of measuring rods in the sleeves are in flush with the internal surface of the testing circular ring, and the sleeves are fixed by bolt spinning. The shaft neck roundness tester is simple in structure, easy to operate, low in cost and easy to carry; and the accurate, qualitative and quantitative measurement of roundness and cylindricity of excircle of the shaft neck can be realized when the operation is carried out in a high altitude environment condition.

Owner:宜兴华永电机有限公司

Anti-electromagnetic-interference pincers-shaped ampere meter device

InactiveCN103267885ATest accurateAvoid interferenceCurrent/voltage measurementMeasurement instrument housingCurrent meterTransformer

The invention discloses an anti-electromagnetic-interference pincers-shaped ampere meter device which comprises a pincers-shaped ampere meter body and a shielding case. The shielding case is arranged around a magnetic iron core of the pincers-shaped ampere meter body, an insulating holding clamp is arranged on the inner side of the shielding case, the shielding case comprises two case body units, and the two case body units are movably connected at the intersecting portion. Due to the fact that the pincers-shaped ampere meter device comprises the pincers-shaped ampere meter body and the shielding case, and the shielding case is arranged around the magnetic iron core of the pincers-shaped ampere meter body, the phenomenon that a traditional pincers-shaped ampere meter is exposed inside a strong electro-magnetic field is changed, the interference to a pincers-shaped ampere meter magnetic loop from a strong magnetic field of a transformer is effectively avoided, and the traditional pincer-shaped ampere meter can accurately detect and display data, and improves the reliability of the measurement data. Due to the fact that the insulating holding clamp is arranged on the inner side of the shielding case, connecting is reliable, and use is convenient. When the case body units are rotated, an opening can be adjusted. The anti-electromagnetic-interference pincers-shaped ampere meter device is simple in structure, economical, practical, and easy to realize and has good popularization and use value.

Owner:PINGDINGSHAN POWER SUPPLY ELECTRIC POWER OF HENAN

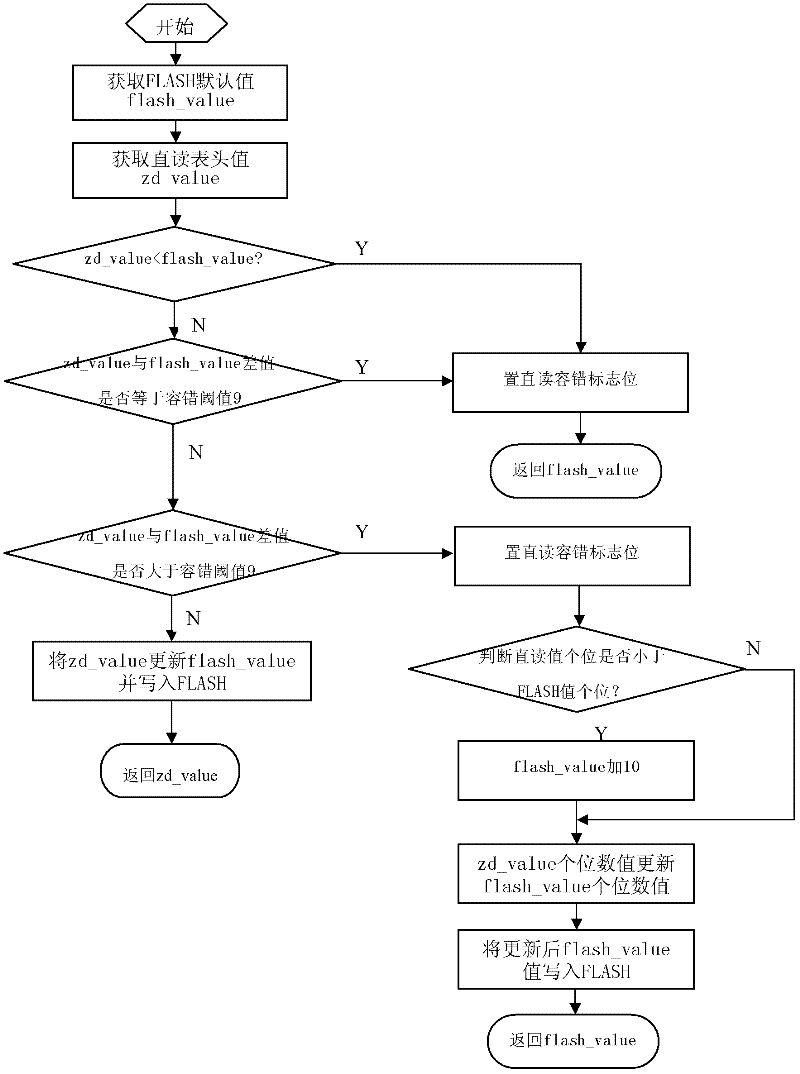

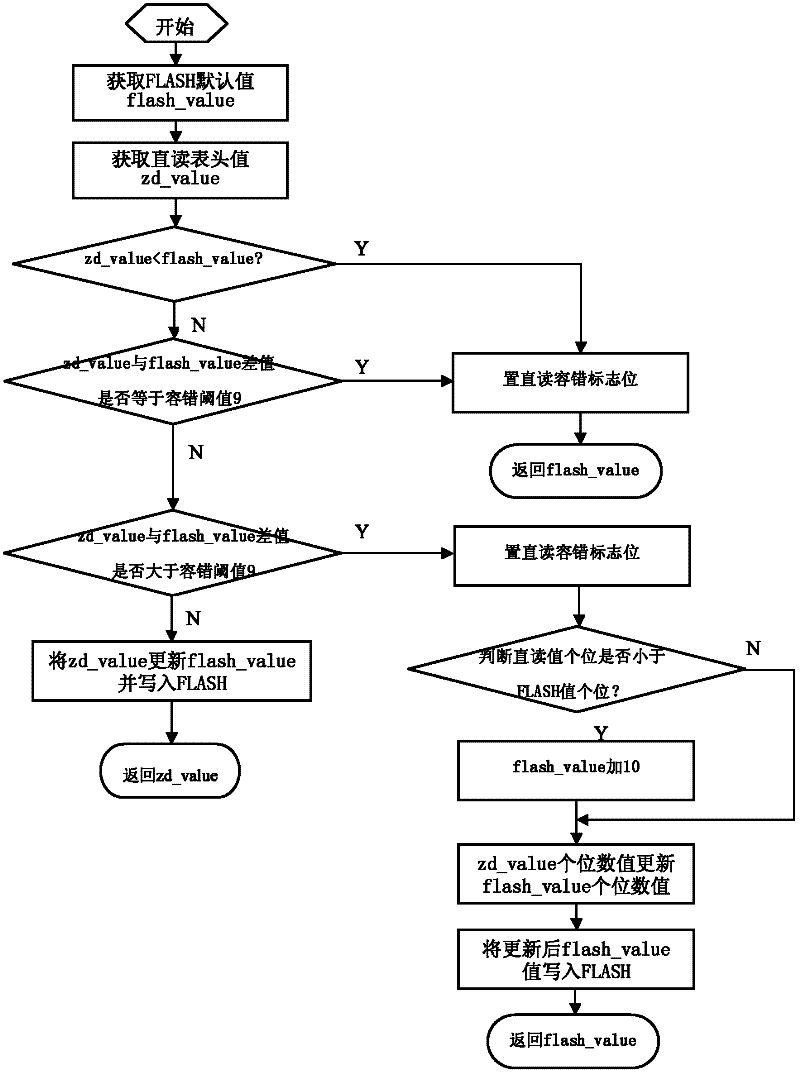

Software fault-tolerant method of character wheel direct reading error

ActiveCN102645250AAccurate readoutNo cumulative errorVolume indication and recording devicesSoftware engineeringSoftware fault

The invention provides a software fault-tolerant method of character wheel direct reading error. A specific FLASH storage region is opened up in a program by software for storing a character wheel reading default value, and each character wheel reading default value is compared with the default value for judgment of accuracy. The software fault-tolerant method aims at the problems of character wheel slant reading and character wheel fault-tolerance in the carry process caused by the factor that most of the direct reading gauge heads on the current market are easy to be obstructed by high light, mechanical character wheel value can be accurately read by utilizing the software fault-tolerant method on the basis of without changing a character wheel mechanical structure, and cumulative error does not exist. With the adoption of the software fault-tolerant method, the character wheel direct reading error can be corrected, fault-tolerant information is uploaded to the background, and reading change is continuously tracked by adopting the method of unit-order actual direct reading and high-order theoretical calculations after fault-tolerance so that the direct reading gauge head has good anti-interference performance.

Owner:CLOUDSENSE SCI & TECH

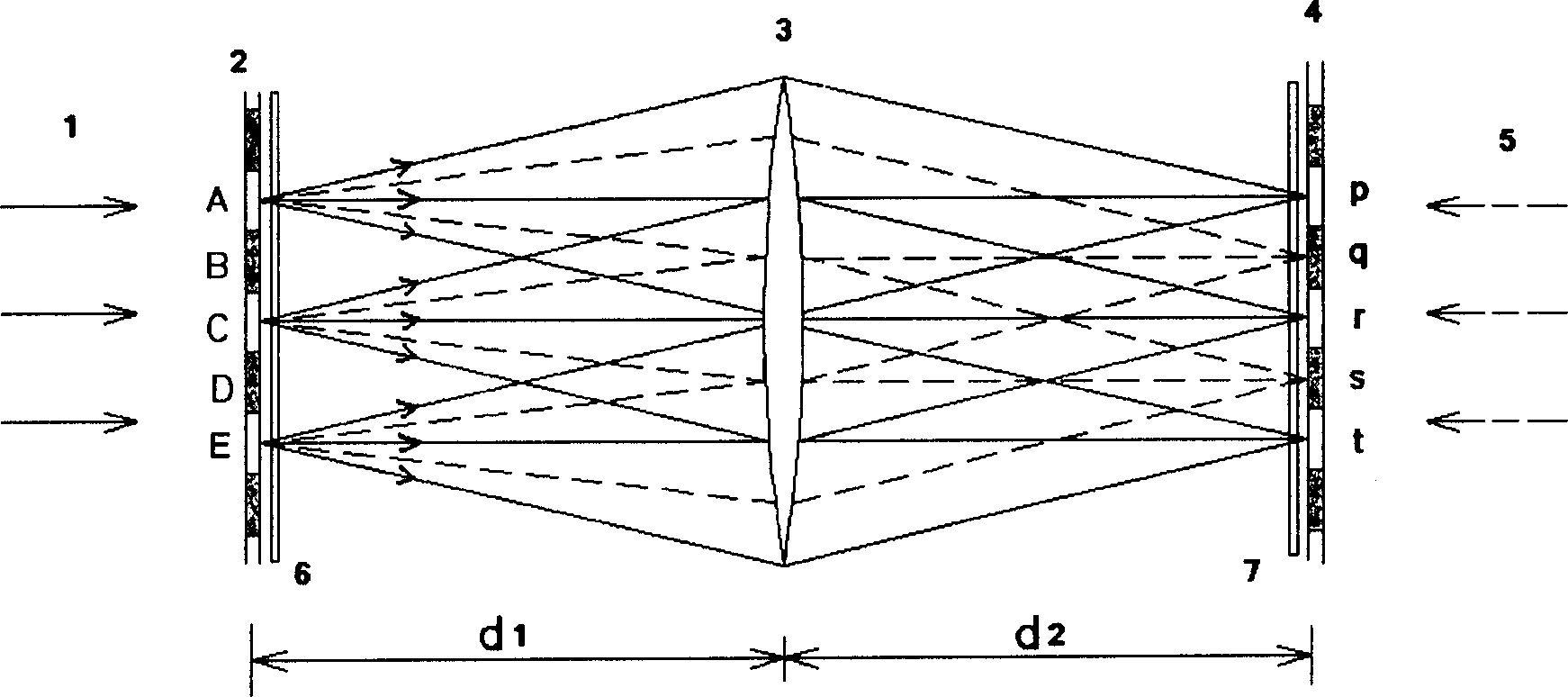

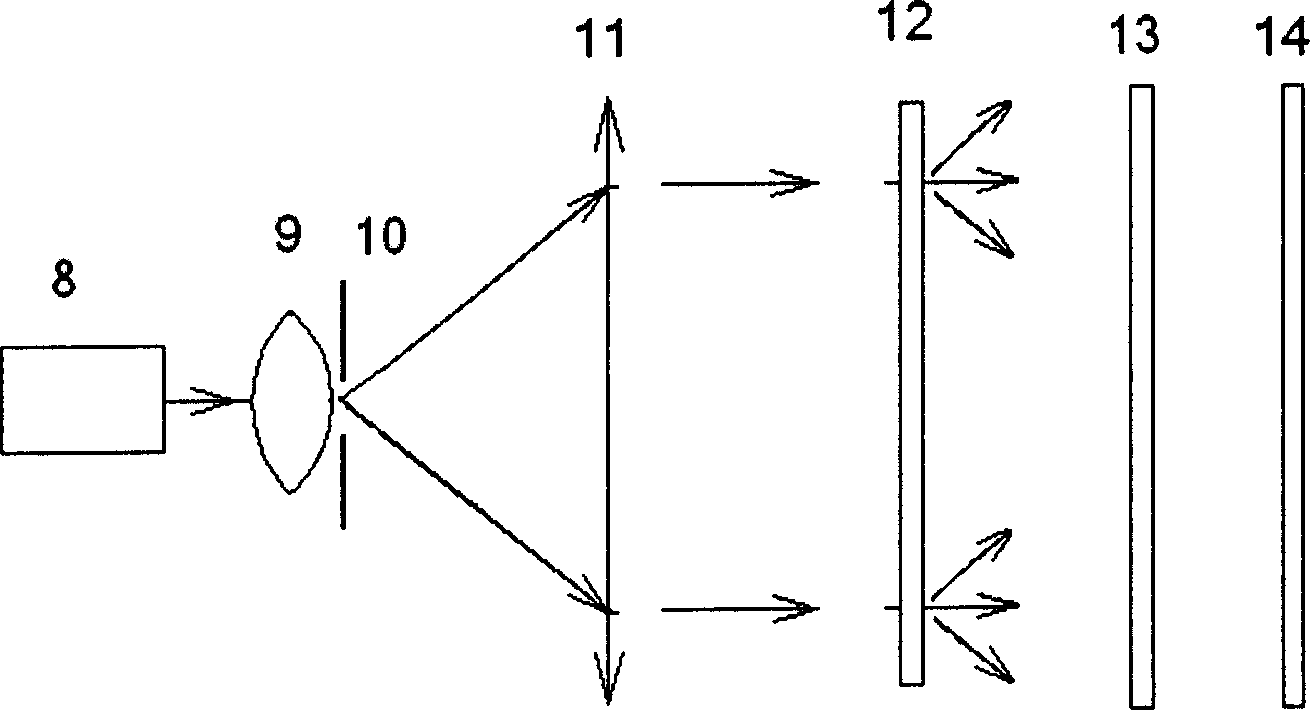

Method and device for improving anti-damage of word and image in machine readable tag

A method for correctly machine - reading pattern and word in countermark on partially damaged valuable document includes using two - valued phase patter to present word and pattern then forming a frame of multigrey scale pattern by using optical mapping conversion device to diffuse each pixel element on original two - valued phase pattern to complete surface of countermark, using orientation angle size of two adjacent sets of speckle Young's interference fringe to present pixel element grey scale. The said method can be used to carry out correct machine - read on damaged document with residual area of 75 % original document.

Owner:HUNAN TONGSEN TECH

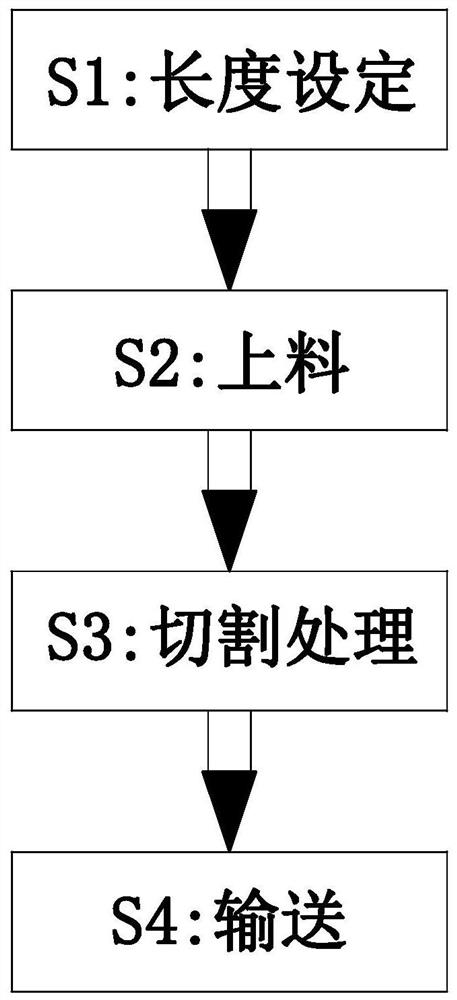

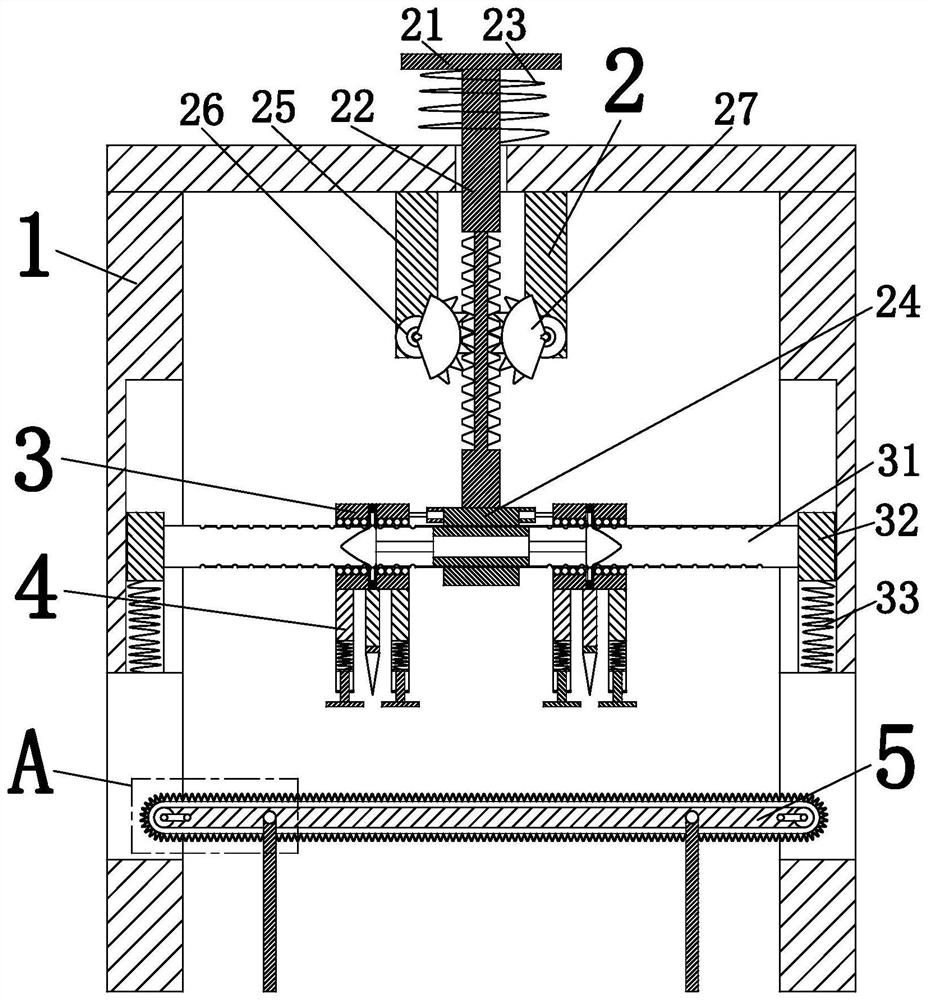

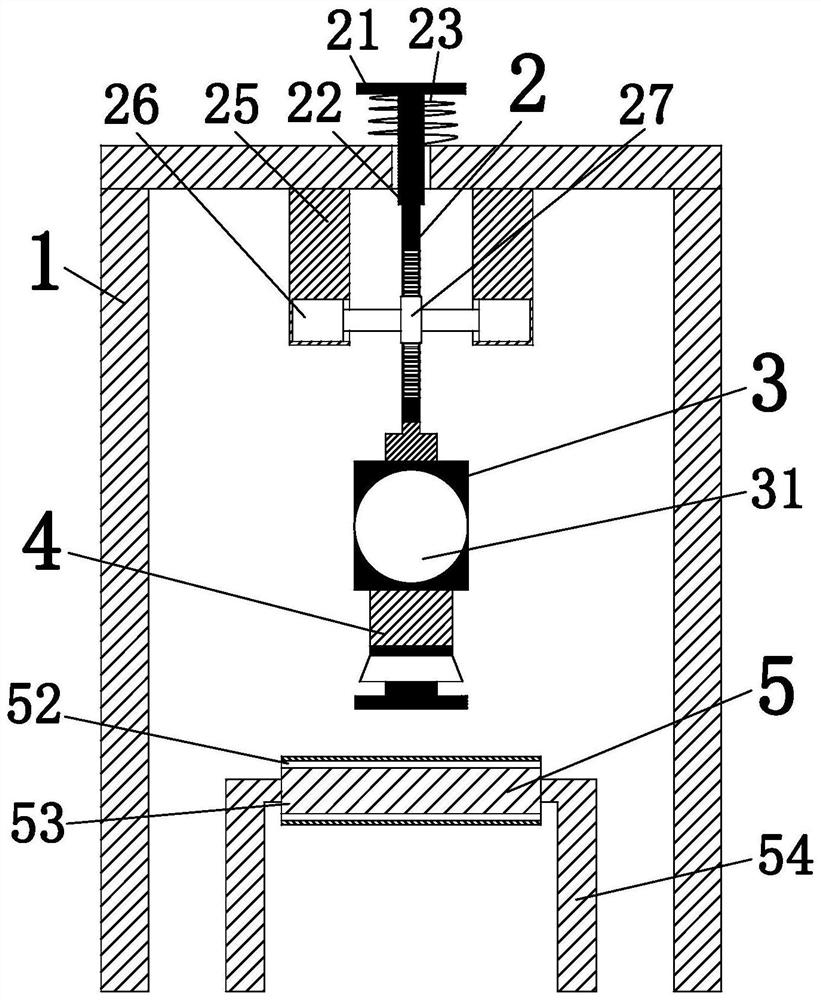

Stainless steel plate net fixed-specification slitting machine and slitting method

ActiveCN111906363AAccurate readoutGuaranteed accuracyShearing machinesMetal working apparatusSteel platesStructural engineering

The invention relates to a stainless steel plate net fixed-specification slitting machine. The stainless steel plate net fixed-specification slitting machine comprises a frame body, a driving device,an adjusting device, a slitting device and a conveying device, the driving device is installed in the middle of the upper end in the frame body, the adjusting device is arranged at the lower end of the driving device in a bilateral symmetry mode, and the slitting device is fixed to the lower end of the adjusting device. According to the stainless steel plate net fixed-specification slitting machine, the problems that in the existing slitting process of a stainless steel plate net, a fixed cutter slitting method is adopted for cutting the steel plate net, in other words, a cut-off cutter is fixed above one end of a workbench, and the end face of the workbench is slit through the cut-off cutter, so that the steel plate net is cut off, the two ends of the cut-off steel plate net are seriouslydeformed, consequently the machining quality and efficiency are reduced, the specification of the steel plate net can only be determined through the part, extending out of the end face of the workbench, of the steel plate net, the machining specification of the steel plate net cannot be accurately guaranteed, and part of the slit steel plate net needs to be machined again before specific use canbe solved.

Owner:佛山市诚和成金属有限公司

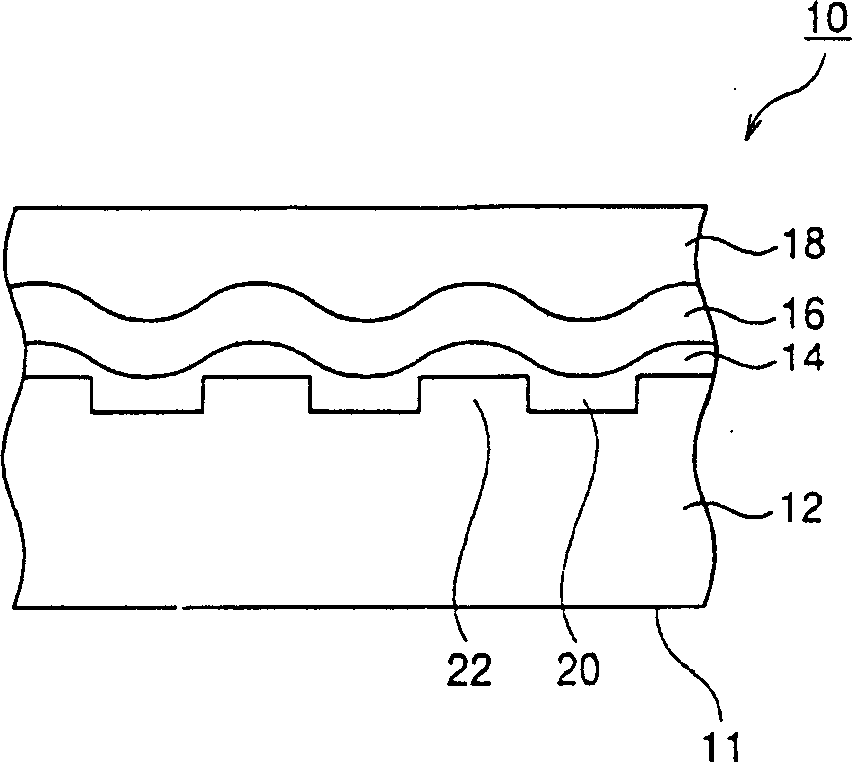

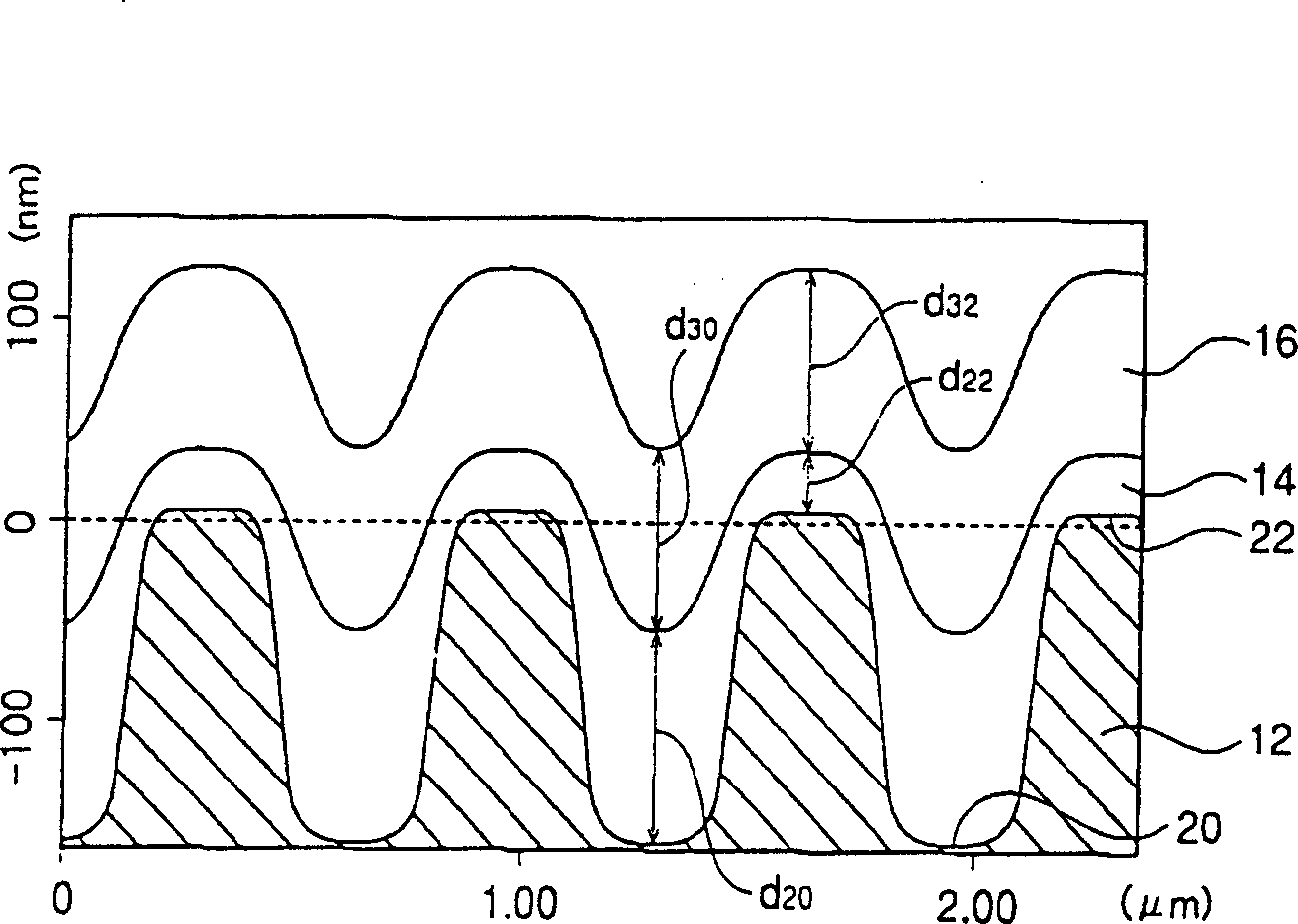

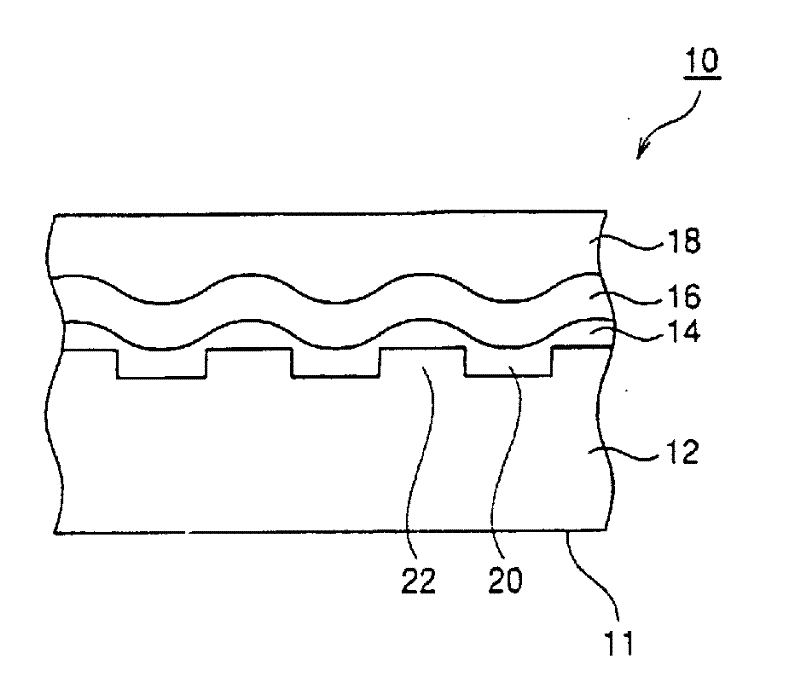

Optical recording media and manufacturing thereof

InactiveCN1363929AReduce error rateReduce leakageDuplicating/marking methodsGroove/land recordingPhysical chemistryEngineering

In an optical recording medium, a recording layer is formed by coating a substrate with a solution of coloring matter comprising a coloring matter dissolved in a solvent comprising a mixture of cyclooctane and at least one hydrocarbon having 6 to 9 carbon atoms other than cyclooctane. The obtained optical recording medium enables the suppression of leakage of the land prepit signal for address information into the RF signal for recorded data at the time of recorded data reproduction, thereby attaining a lowering of error rate.

Owner:MITSUI CHEM INC

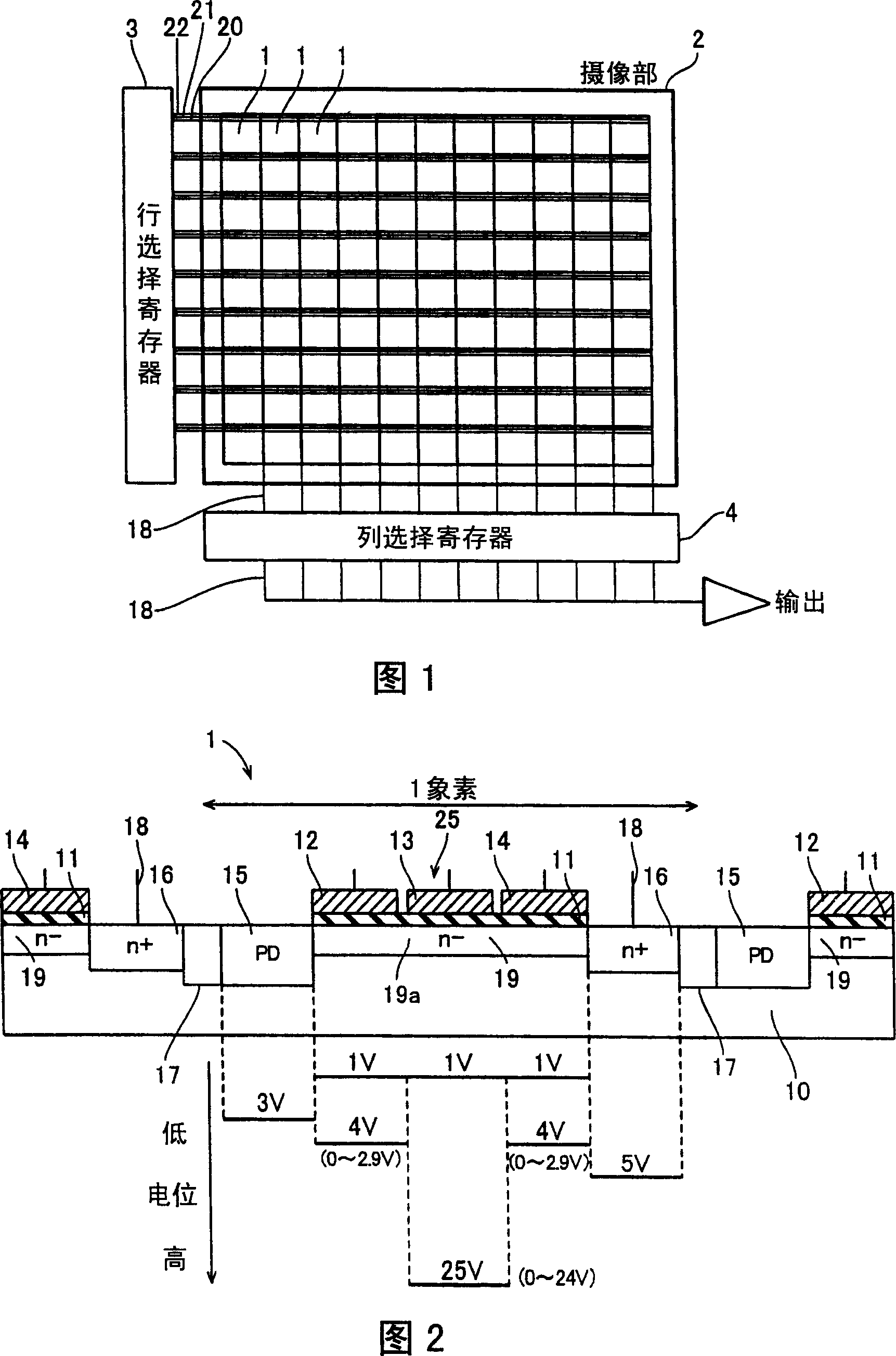

Imaging device

InactiveCN101013712AAccurate readoutSuppress mix-inRadiation controlled devicesCharge carrierMiniaturization

The invention provides an imaging device. The imaging device includes a carrier storage portion for storing carriers generated by photoelectric conversion, having a photoelectric conversion function, a multiplier section including a multiplier electrode applying an electric field for multiplying carriers due to impact ionization by an electric field, one first transfer electrode so provided between the carrier storage portion and the multiplier electrode as to be adjacent to the carrier storage portion and the multiplier electrode. Thereby, the present invention provides an imaging device capable of multiplying carriers and miniaturizing the device.

Owner:SANYO ELECTRIC CO LTD

Flute-shaped tube jet flow impingement curved surface heat exchange test device

ActiveCN107817121ARealize flow heat transfer characteristic testEasy to replaceHydrodynamic testingFluteEngineering

The invention discloses a flute-shaped tube jet flow impingement curved surface heat exchange test device. An air supply flute-shaped tube is fixed on a top end of a push rod of a push rod motor via aflute-shaped tube positioning assembly and a push rod connecting assembly, two ends of an outer shell of the push rod motor are respectively fixed on a bottom plate and a top plate via a motor positioning assembly, four fastening support rods are fixed in installation holes of a top plate after penetrating beyond a bottom plate, four fastening and positioning rods are fixed in installation holesof a second side plate after penetrating beyond a first side plate, a jet flow curved surface is mounted on conformal curved surfaces of the first side plate and the second side plate via gaskets, anda jet flow curved surface positioning assembly is mounted on a surface of the first side plate. The test device disclosed in the invention can be used for conducting in-depth research on characteristics of flow heat exchange of flute-shaped tube jet flow impingement curved surface; effects exerted by factors such as structure parameters of the flute-shaped tube, curvature of the curved surface and the like on heat exchange performance of a jet flow surface can be explained; jet flow heat exchange rules can be summed up; structure design of a surface, having a complex curvature change, of an airplane anti-icing chamber can be guided and subjected to performance assessing operation.

Owner:BEIHANG UNIV

Shaft neck roundness tester

ActiveCN103808239AAccurate readoutRealize accurate and quantitative measurementMechanical counters/curvatures measurementsEngineeringScrew thread

The invention discloses a shaft neck roundness tester. The shaft neck roundness tester comprises a testing circular ring, three dial indicator supports arranged into trisection around an axis of testing circular ring, dial indicators arranged in the dial indicator supports and a raised handle arranged on the external surface of the testing circular ring, wherein the dial indicator supports are in shaft sleeve shapes, a connection part at the bottom of the tester is connected with a through hole which is formed in the external surface of the testing circular ring, and the external surface of the testing circular ring is exposed at the upper end of the tester and a threaded hole which is connected with an inner hole is formed in a side wall of the tester; a bolt is internally screwed in the threaded hole, sleeves at the bottom of the dial indicators are stretched into the inner holes of the dial indicator supports, measuring heads which are located at the ends of measuring rods in the sleeves are in flush with the internal surface of the testing circular ring, and the sleeves are fixed by bolt spinning. The shaft neck roundness tester is simple in structure, easy to operate, low in cost and easy to carry; and the accurate, qualitative and quantitative measurement of roundness and cylindricity of excircle of the shaft neck can be realized when the operation is carried out in a high altitude environment condition.

Owner:宜兴华永电机有限公司

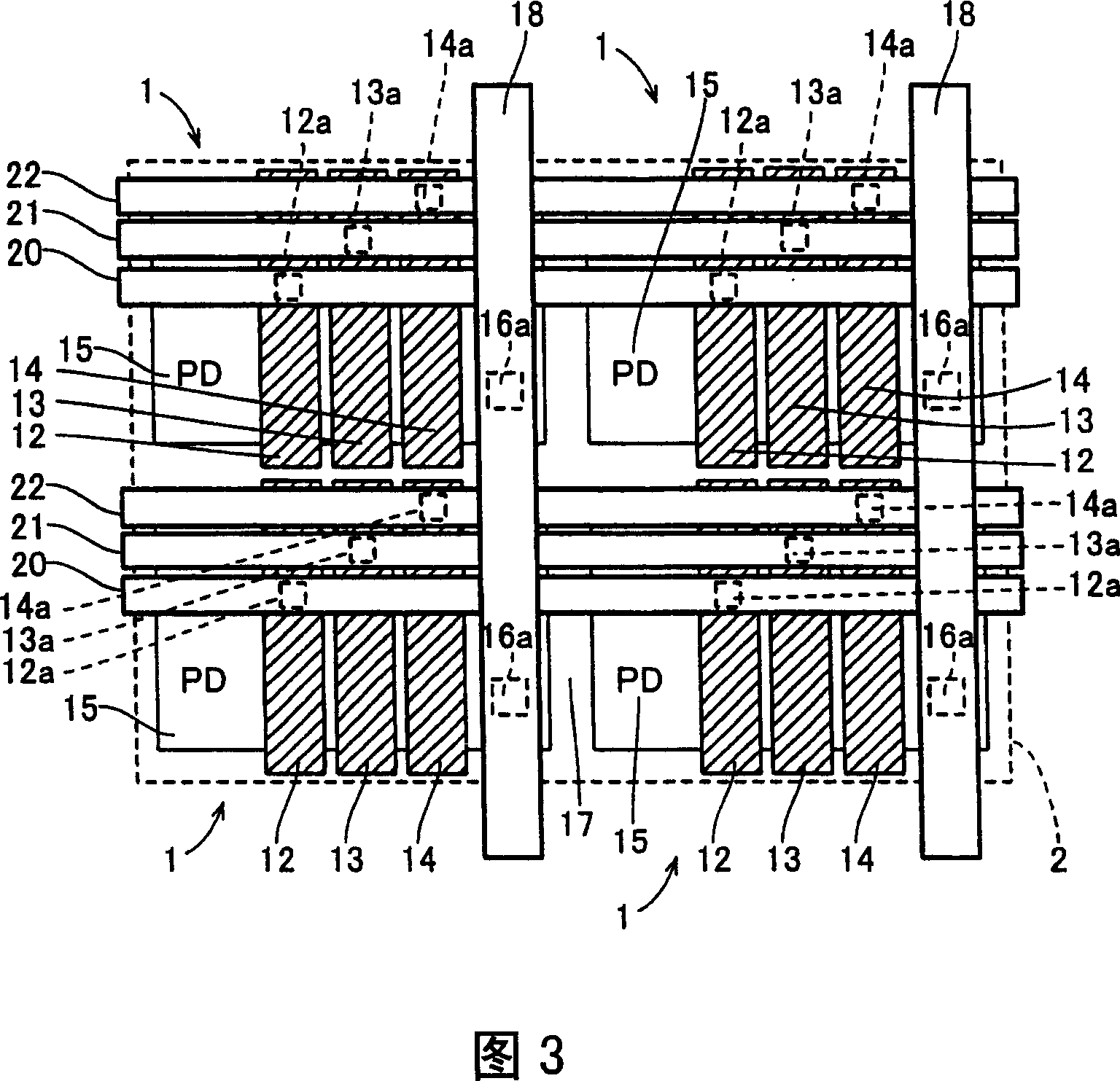

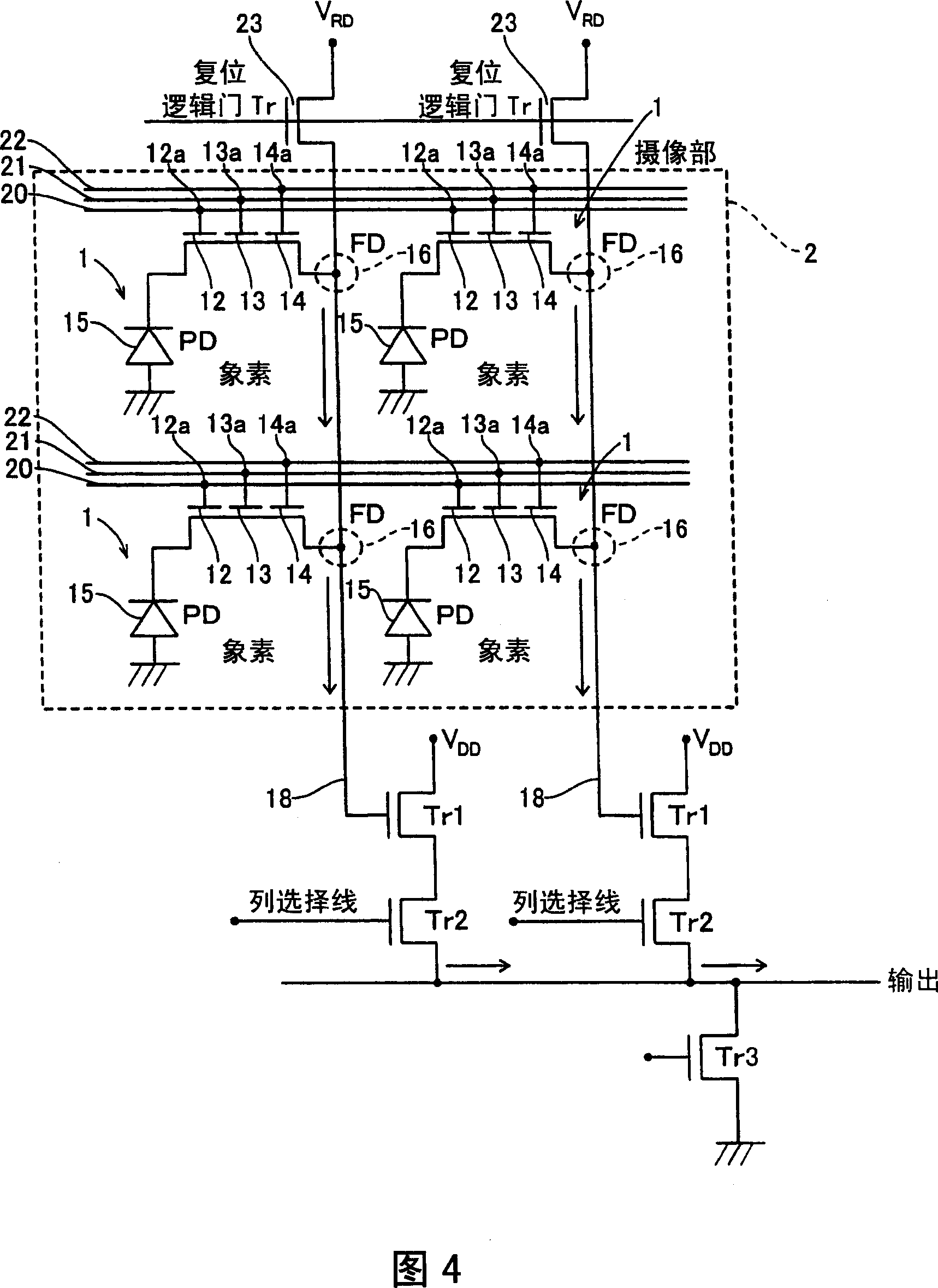

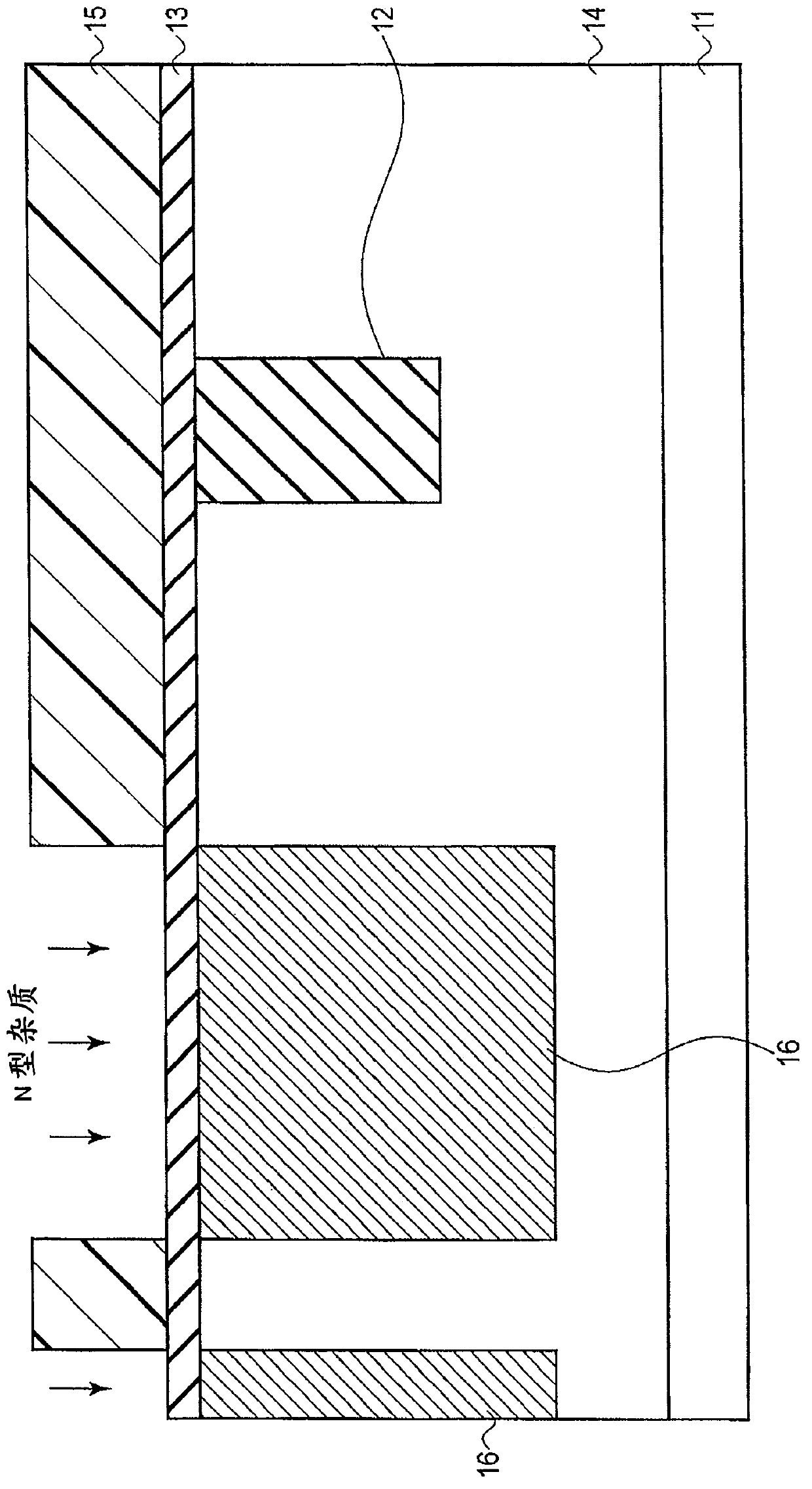

Solid state imaging device and manufacturing method thereof

InactiveCN103137634AAccurate readoutTelevision system detailsSolid-state devicesPhysicsElectrically conductive

The invention provides a solid state imaging device capable of accurately reading electric charge accumulated in a photodiode and a manufacturing method thereof. The solid state imaging device provided by an embodiment comprises a semiconductor substrate, a photodiode which is disposed in the semiconductor substrate and is provided with a first conductive type semiconductor layer, a shielding layer which is disposed on the above photodiode and contains a second conductive type semiconductor layer in the upper portion or the whole of the shielding layer; and a transmission transistor which is disposed on the semiconductor substrate and transmits the electric charge accumulated in the photodiode to a floating diffusion layer. The top surface of the shielding layer is higher than that of the semiconductor substrate.

Owner:KK TOSHIBA

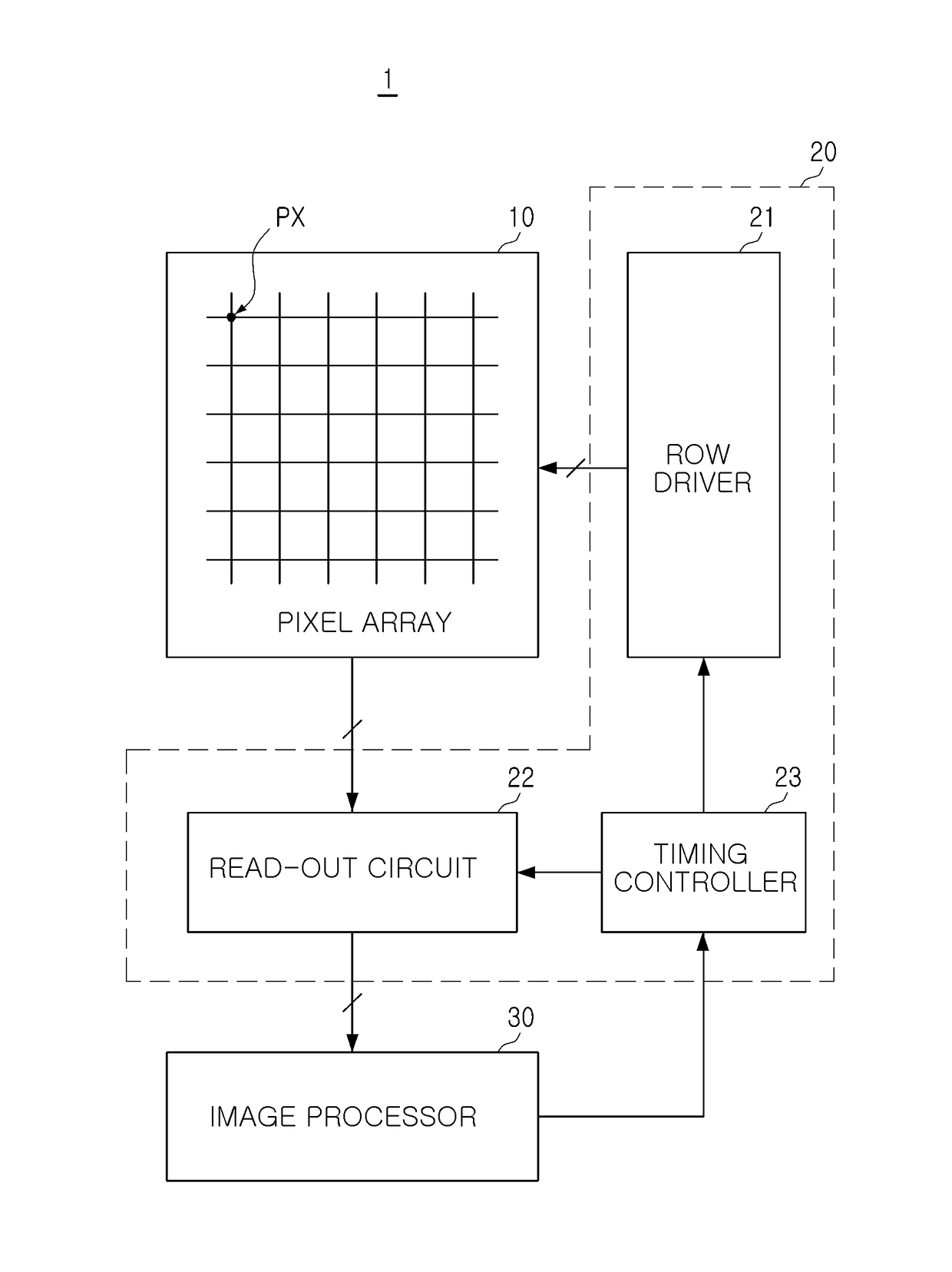

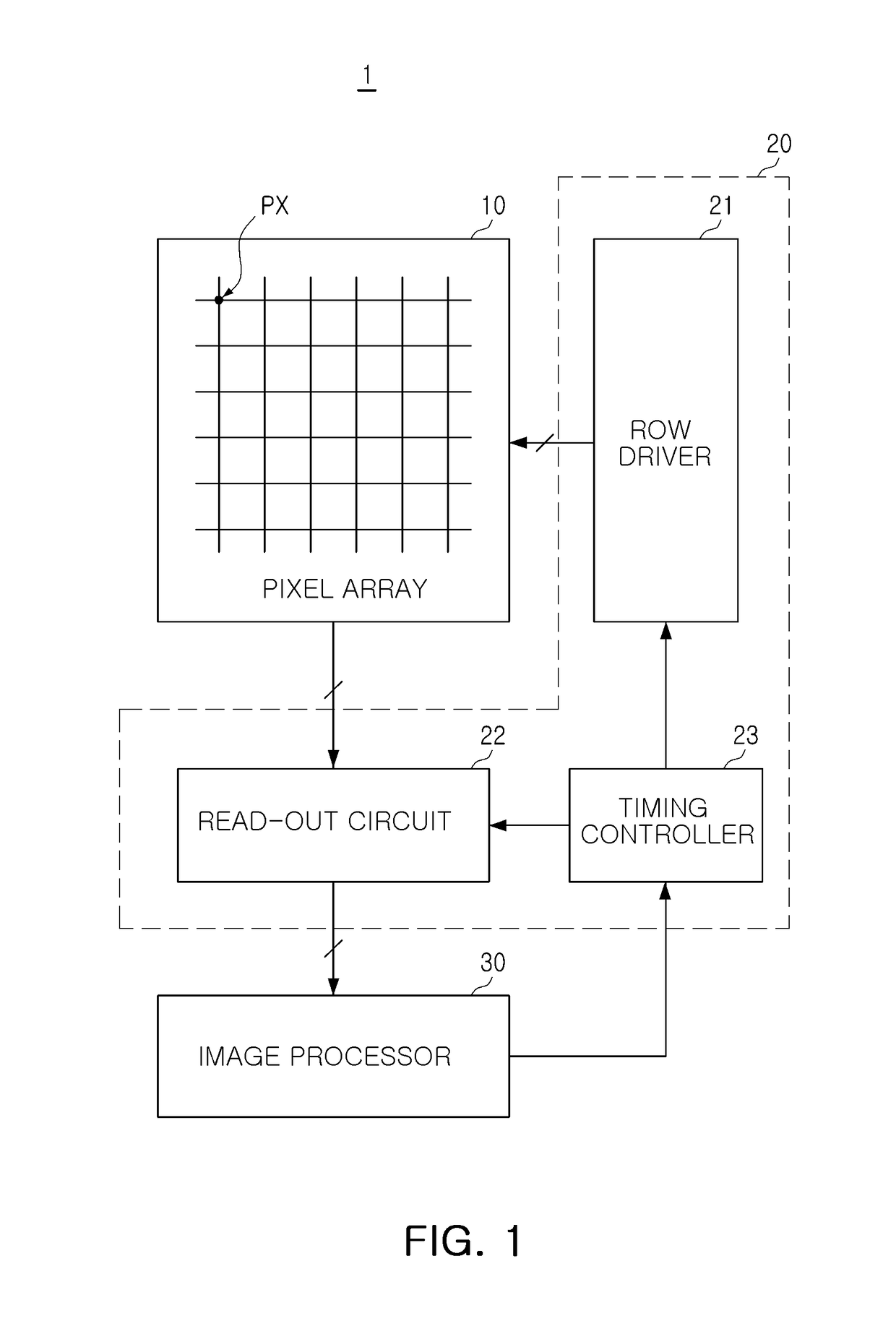

Image sensor

ActiveUS20180152653A1Minimizing effect of noiseAccurate readoutTransistorTelevision system detailsImage sensorVoltage reference

An image sensor includes a photoelectric device generating an electric charge from light; a feedback device generating a reset voltage using a predetermined reference voltage; and a pixel circuit generating a pixel voltage using the reset voltage and the electric charge, setting the reset voltage to the reference voltage using the feedback device a first period, and outputting the pixel voltage and the reset voltage during a second period.

Owner:SAMSUNG ELECTRONICS CO LTD

Transparent flexible ruler

The invention discloses a transparent flexible ruler which includes a shell, a graduation ruler and a bending stop block. The shell is provided with an opening. The graduation ruler is wound in the shell and can be pulled from the opening. The graduation ruler is provided with an end part. The bending stop block is arranged at the end part and capable of being clamped at the opening. The graduation scale is transparent. The transparent flexible ruler uses a transparent material to make the graduation ruler. During scale reading, the scale can coincide accurately with the edge of a measured object and the number can be read accurately so that a condition that when an object, which is narrower in width, is measured, the graduation ruler is incapable of accurate alignment is prevented.

Owner:陈少华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com