Imaging device

An imaging device and carrier technology, applied in radiation control devices, etc., can solve problems such as difficulty in miniaturization of imaging devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

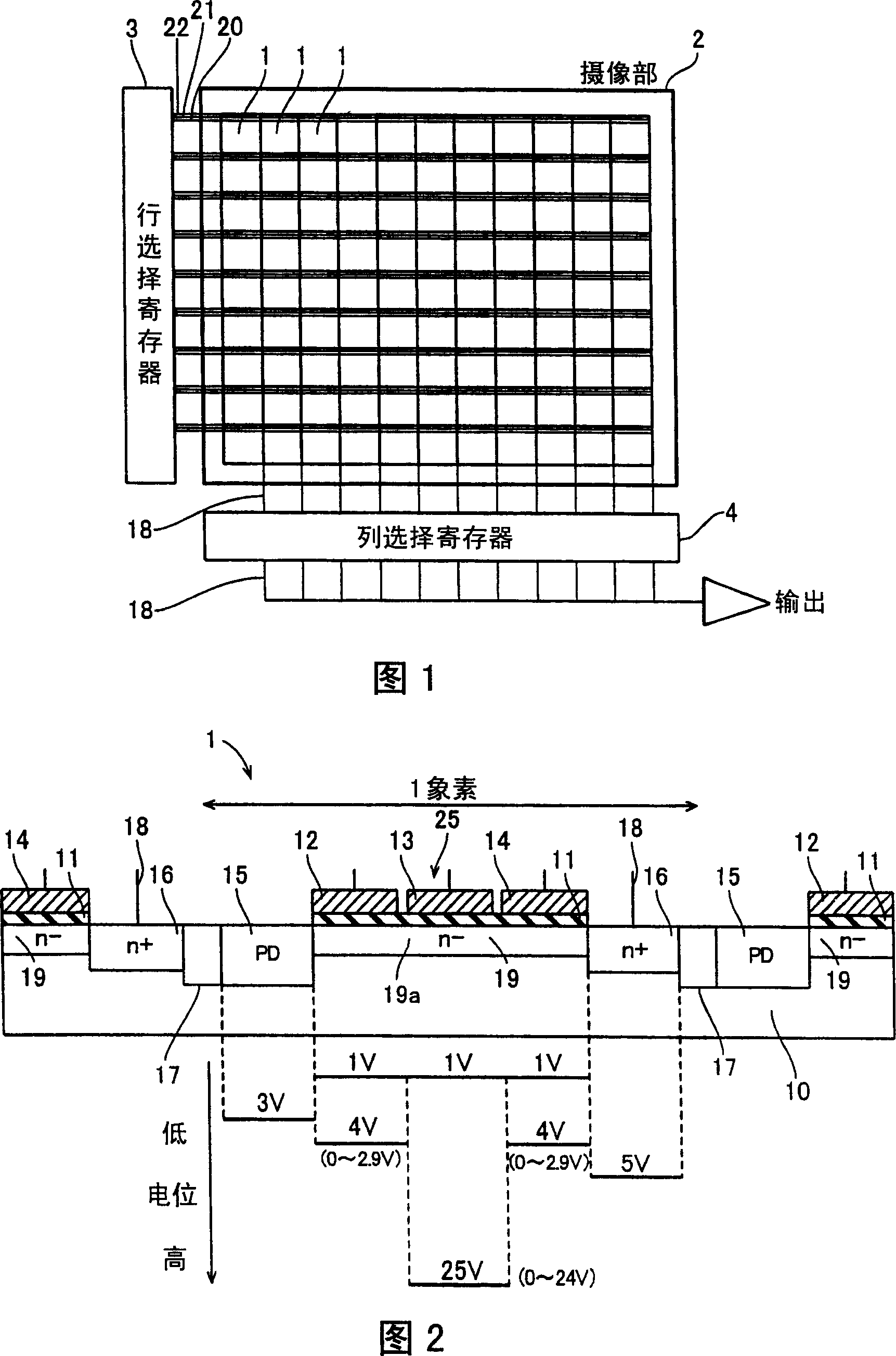

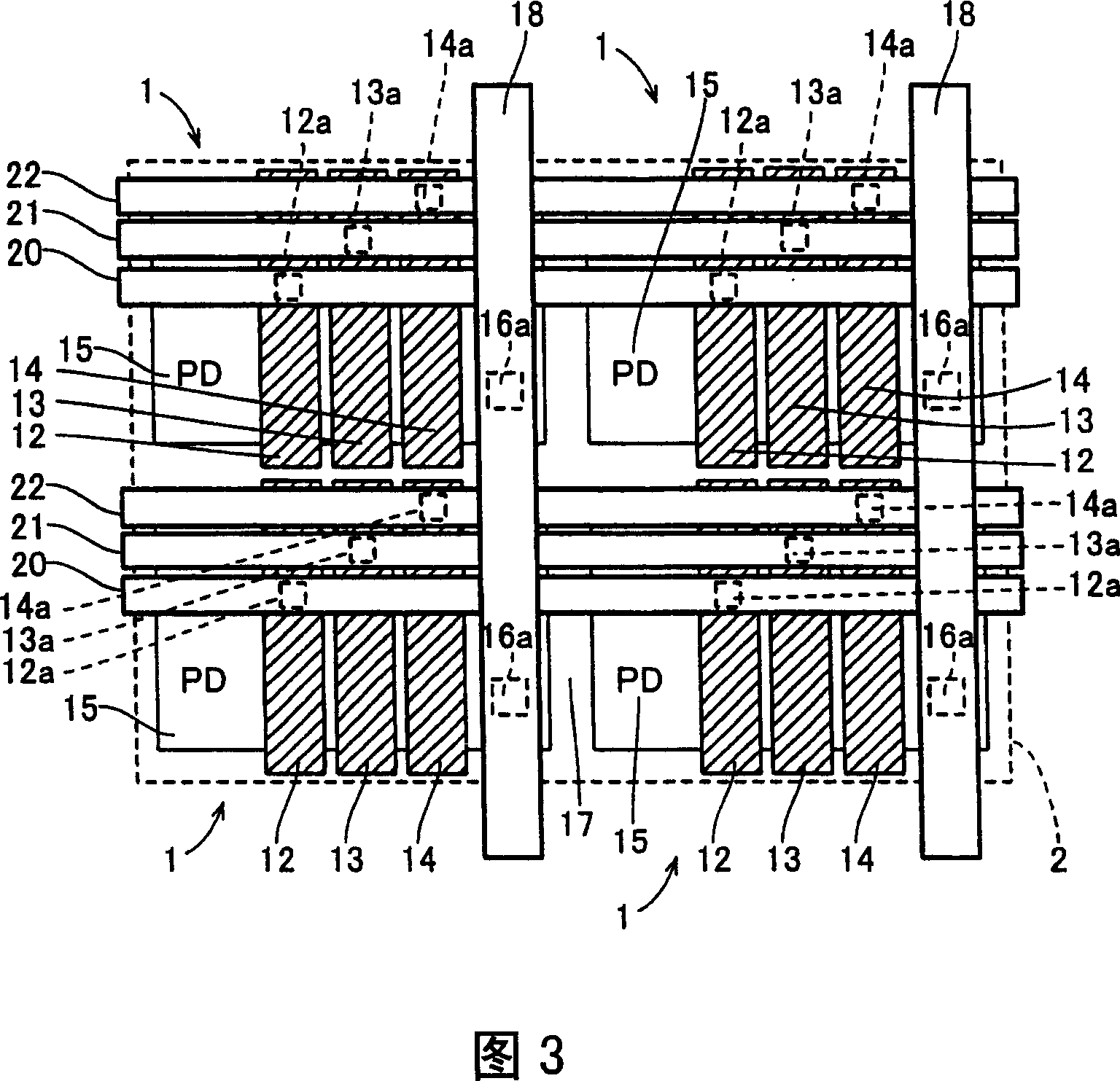

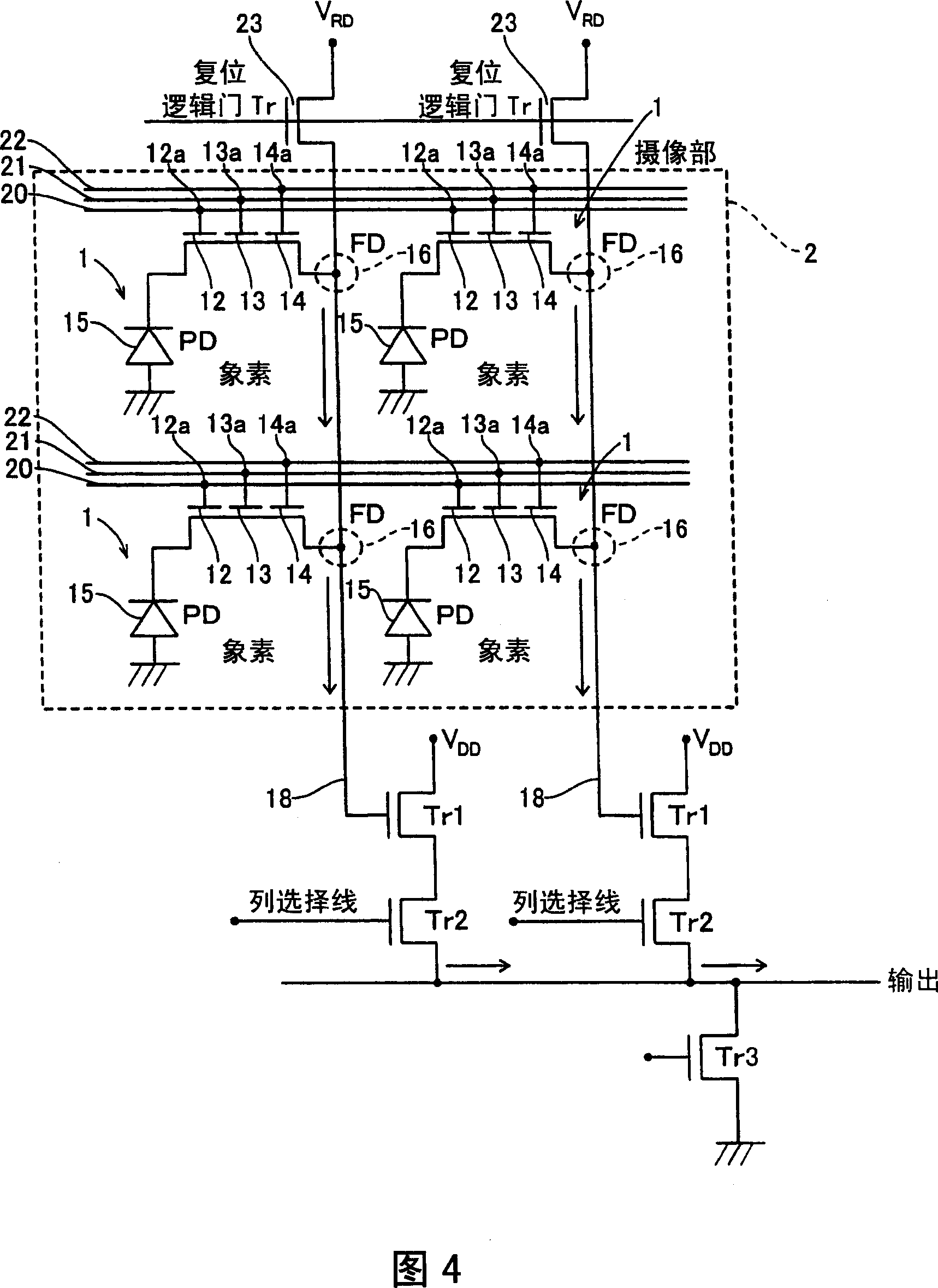

[0046] First, the structure of the CMOS image sensor according to the first embodiment will be described with reference to FIGS. 1 to 4 .

[0047] As shown in FIG. 1 , the CMOS image sensor according to the first embodiment includes an imaging unit 2 including a plurality of pixels 1 , a row selection register 3 , and a column selection register 4 . In addition, as shown in FIG. 2 , the pixel 1 has three gate electrodes: a p-type silicon substrate 10 , a gate insulating film 11 , a transfer gate electrode 12 , a multiplication gate electrode 13 and a readout gate electrode 14 . polar electrode, a photodiode portion (PD) 15 , a floating diffusion region 16 composed of an n-type impurity region, and an element isolation region 17 . In addition, gate insulating film 11 is formed on the surface of p-type silicon substrate 10 at predetermined intervals. In addition, the transfer gate electrode 12 , the doubler gate electrode 13 , and the readout gate electrode 14 are formed in pre...

no. 2 approach

[0069] Referring to FIG. 9 , the configuration of a CMOS image sensor including pixels 30 formed such that photodiode portions 15 are adjacent to readout gate electrodes 14 in the second embodiment, which is different from the first embodiment described above, will be described.

[0070] The cross-sectional structure of the pixel 30 of the CMOS image sensor according to the second embodiment is as shown in FIG. In addition, on the surface of the p-type silicon substrate 10 of each pixel 30 surrounded by the element isolation region 17, a transfer groove composed of an n-type impurity region is sandwiched at a predetermined interval from one side of the element isolation region 17. In the form of the track 31, the photodiode portion 15 is formed. In addition, on the surface of the p-type silicon substrate 10 of each pixel 30, a floating diffusion is formed at a predetermined interval from the photodiode portion 15 so as to sandwich the transfer channel 32 composed of an n-type ...

no. 3 approach

[0083] Referring to FIG. 11 , the structure of a CMOS image sensor including a pixel 40 in which a transfer gate electrode 42 is formed on a photodiode portion 15 in this third embodiment, which is different from the above-mentioned first embodiment, will be described.

[0084]The cross-sectional structure of the pixel 40 of the CMOS image sensor according to the third embodiment, as shown in FIG. Film 41. A transfer gate electrode 42 is formed in a region corresponding to the photodiode portion 15 on the upper surface of the gate insulating film 41 . In addition, the transfer gate electrode 42 is an example of the "second transfer electrode" of this invention. In addition, in a region corresponding to the transfer channel 19 on the upper surface of the gate insulating film 41, the transfer gate electrode 12, the multiplication gate electrode 13, and the readout gate electrode 12 are sequentially formed at predetermined intervals from the photodiode portion 15 side. electrod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com