Solid state imaging device and manufacturing method thereof

A technology of solid-state imaging and manufacturing methods, which is applied in the direction of electric solid-state devices, radiation control devices, semiconductor devices, etc., and can solve problems such as performance degradation of optical sensors, reduction of conduction current, and degradation of transistor characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach )

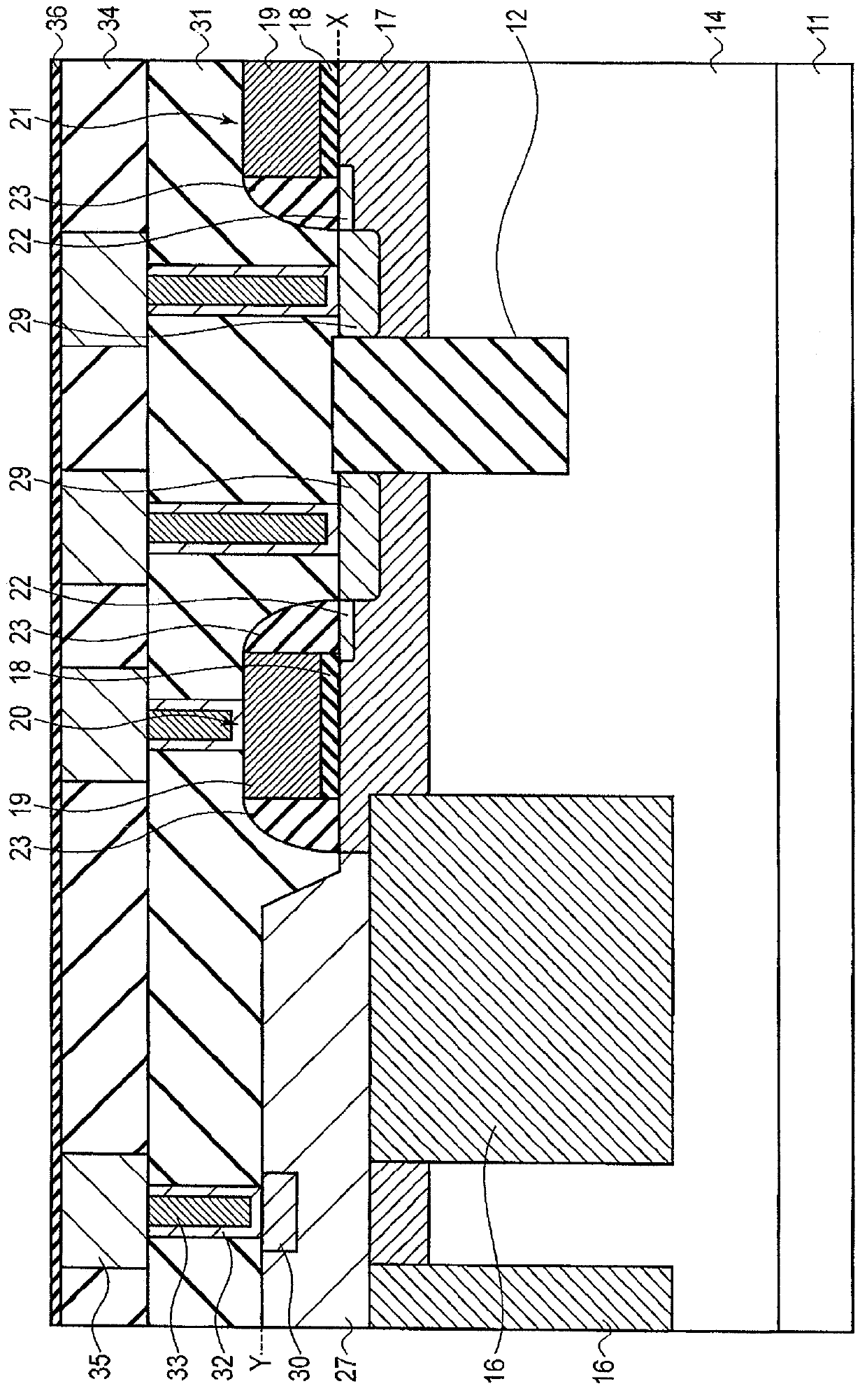

[0035] The solid-state imaging device according to the first embodiment includes a CMOS sensor. figure 1 It is a cross-sectional view of the solid-state imaging device according to the first embodiment.

[0036] A solid-state imaging device includes a pixel array including a plurality of pixels. Each pixel includes: a photoelectric conversion element (photodiode) 16 that converts incident light into charges; a transfer transistor 20 that transfers the charges accumulated in the photodiode 16 to the floating diffusion layer 29; and a voltage of the floating diffusion layer 29 as a signal. Level output amplifier transistor 21 and so on.

[0037] figure 1 , the symbol “X” represents the position of the top surface of the semiconductor substrate (eg silicon substrate) 11 . Inside the silicon substrate 11 , a separation layer 14 is provided for electrically separating adjacent photodiodes 16 . The separation layer 14 includes a P-type semiconductor layer. In the surface region...

no. 2 Embodiment approach )

[0068] In the second embodiment, as the semiconductor layer constituting the shield layer, the same semiconductor material as that of the semiconductor layer constituting the gate electrode of the MOSFET is used. Furthermore, simultaneously with the step of forming the semiconductor layer for the gate electrode, the semiconductor layer for the shield layer is formed.

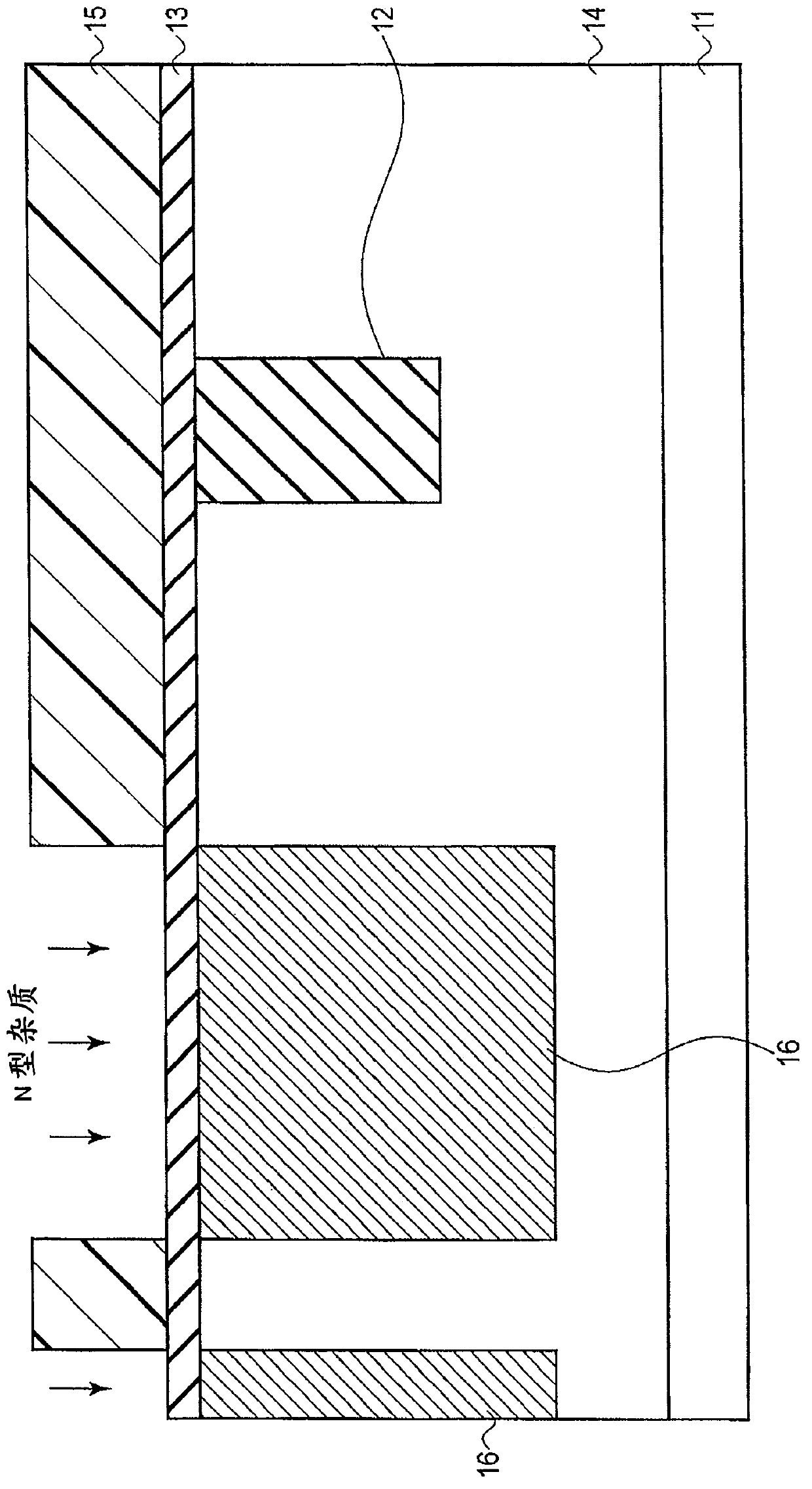

[0069] Figure 14 It is a cross-sectional view of the solid-state imaging device of the second embodiment. Similar to the first embodiment, an embedded photodiode 16 is provided in the silicon substrate 11 . That is, the top surface of the photodiode 16 is lower than the top surface X of the silicon substrate 11 . A shielding layer 27 is provided on the photodiode 16 . The top surface Y of the shield layer 27 is higher than the top surface X of the silicon substrate 11 . In addition, as the semiconductor layer constituting the shield layer 27 , the same semiconductor material as the semiconductor layer const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com