Shaft neck roundness tester

A detector and roundness technology, which is applied in the field of wind turbine rotor shaft outer circle journal roundness detector, can solve the problems of inconvenience, impact on bearing life, and large instrument volume, and achieve portability, ease of operation, and low cost. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

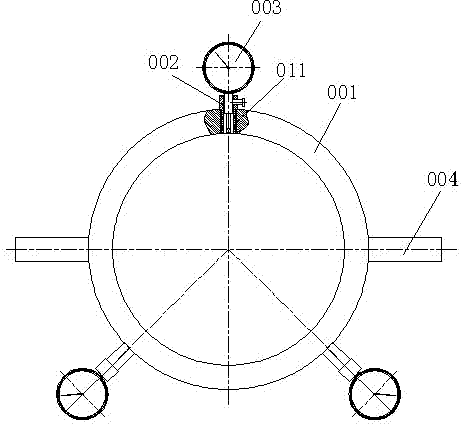

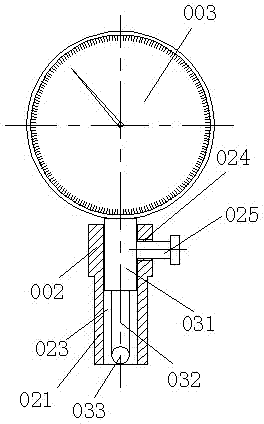

[0012] The journal roundness detector includes a detection ring 001, three dial indicator supports 002 arranged in three equal parts around the detection ring 001 axis, a dial indicator 003 installed in the dial indicator support 002 and a setting The protruding handle 004 on the outer surface of the detection ring 001, the dial indicator support 002 is in the shape of a sleeve, the bottom connection part 021 is connected with the through hole 011 opened on the outer surface of the detection ring 001, and the upper end 002 is exposed for detection On the outer surface of the ring 001, there is a threaded hole 024 communicating with the inner hole 023 on the side wall. The threaded hole 024 is screwed with a bolt 025, and the bottom sleeve 031 of the dial indicator 003 extends into the dial indicator support. In the inner hole 023 of the seat 002, the side measuring head 033 at the end of the measuring rod 032 in the sleeve 031 is flush with the inner surface of the detection ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com