Tool for measuring angle of tapered hole at bottom of deep groove cavity

A technology of tapered holes and deep grooves, which is applied in the field of instruments for quickly measuring the angle of tapered holes at the bottom of deep grooves. It can solve the problems of high cost, difficulty in observing the scale line of plug gauges, and inability to read the specific value of hole taper.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

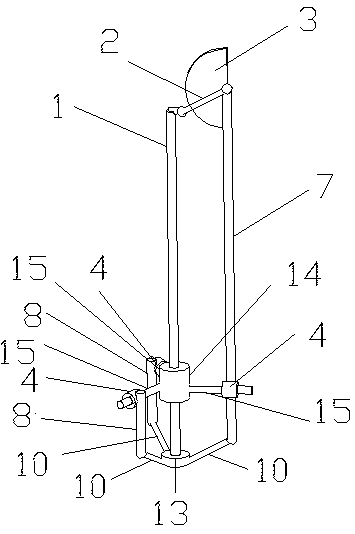

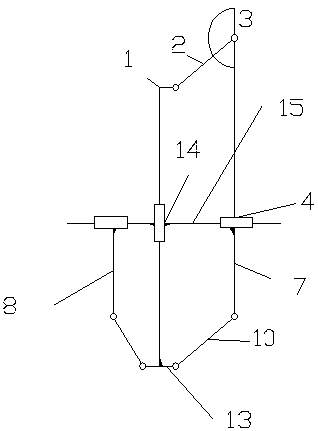

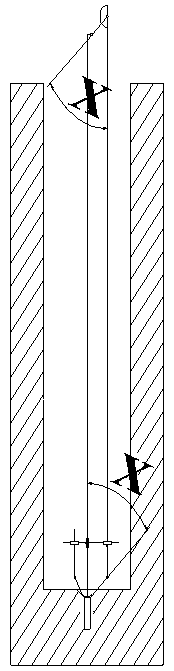

[0023] A tool for measuring the angle of a tapered hole at the bottom of a deep groove cavity includes a central rod 1, the top of which is connected to one end of a connecting rod 2, and the other end of the connecting rod 2 is connected to a protractor 3, and the protractor 3 is arranged on the auxiliary measuring rod 7, and the lower part of the central rod 1 is provided with a vertical sliding connection block 14, and the vertical sliding connection block 14 is connected with three cross bars 15, and one of the cross bars 15 is connected by lateral sliding The block 4 is connected with the auxiliary measuring rod 7, and the remaining two cross bars 15 are respectively connected with an end-stop connecting rod 8 through the laterally sliding connecting block 4, and the bottom of the central rod 1 is connected with a stop-end cylinder 13, and the stop-stop cylinder 13 is connected to the bottom of the central rod 1. The end cylinder 13 is respectively connected with the two e...

Embodiment 2

[0025] A tool for measuring the angle of a taper hole at the bottom of a deep groove cavity includes a central rod 1, the top of which is connected to one end of a connecting rod 2, and the other end of the connecting rod 2 is connected to a protractor 3, and the protractor 3 is arranged on the auxiliary measuring rod 7, and the lower part of the central rod 1 is provided with a vertical sliding connection block 14, and the vertical sliding connection block 14 is connected with three cross bars 15, and one of the cross bars 15 is connected by a horizontal sliding The block 4 is connected with the auxiliary measuring rod 7, and the remaining two cross bars 15 are respectively connected with an end-stop connecting rod 8 through the laterally sliding connecting block 4, and the bottom of the central rod 1 is connected with a stop-end cylinder 13, and the stop-stop cylinder 13 is connected to the bottom of the central rod 1. The end cylinder 13 is respectively connected with the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com