Engineering illuminating lamp with remote monitoring system

A remote monitoring system and lighting technology, applied in lighting devices, lighting devices, with built-in batteries, etc., can solve the problem that engineering lighting cannot be remotely monitored, the service life of the lamp is greatly affected, and the engineering lighting is inconvenient to move, etc. problems, to achieve the effect of increasing practicability, increasing the scope of application, and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

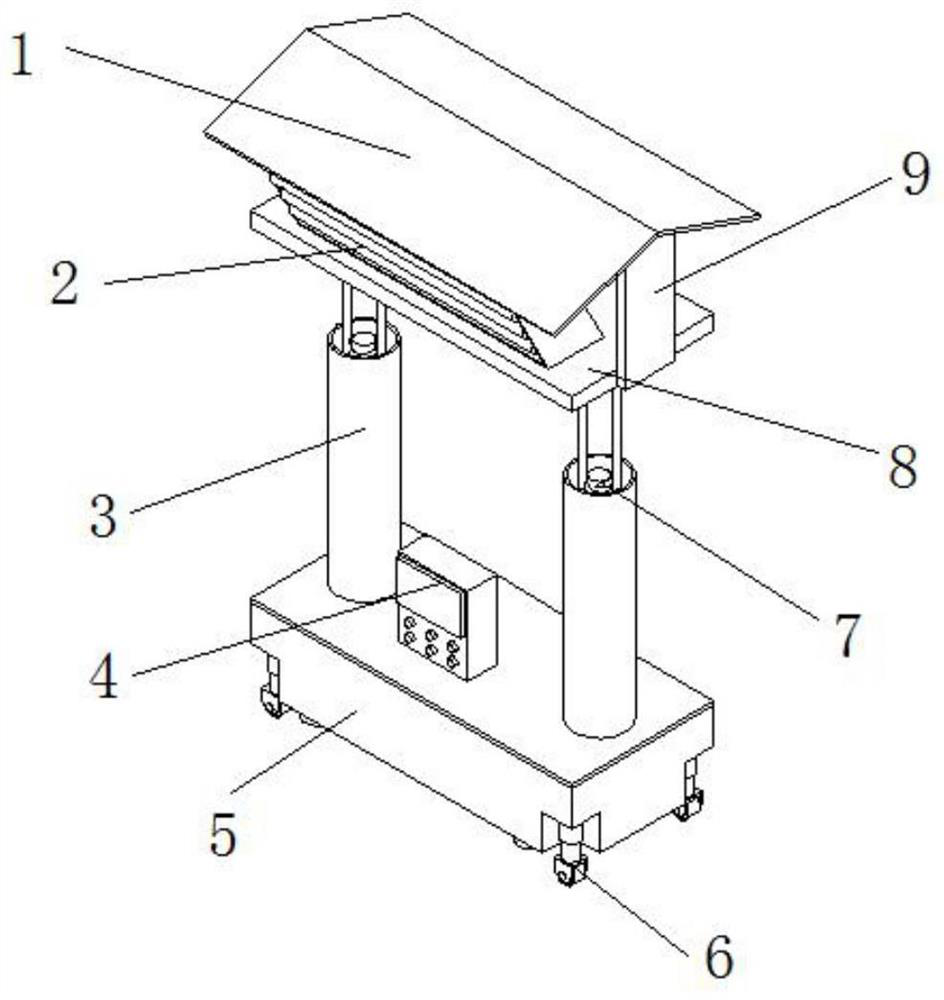

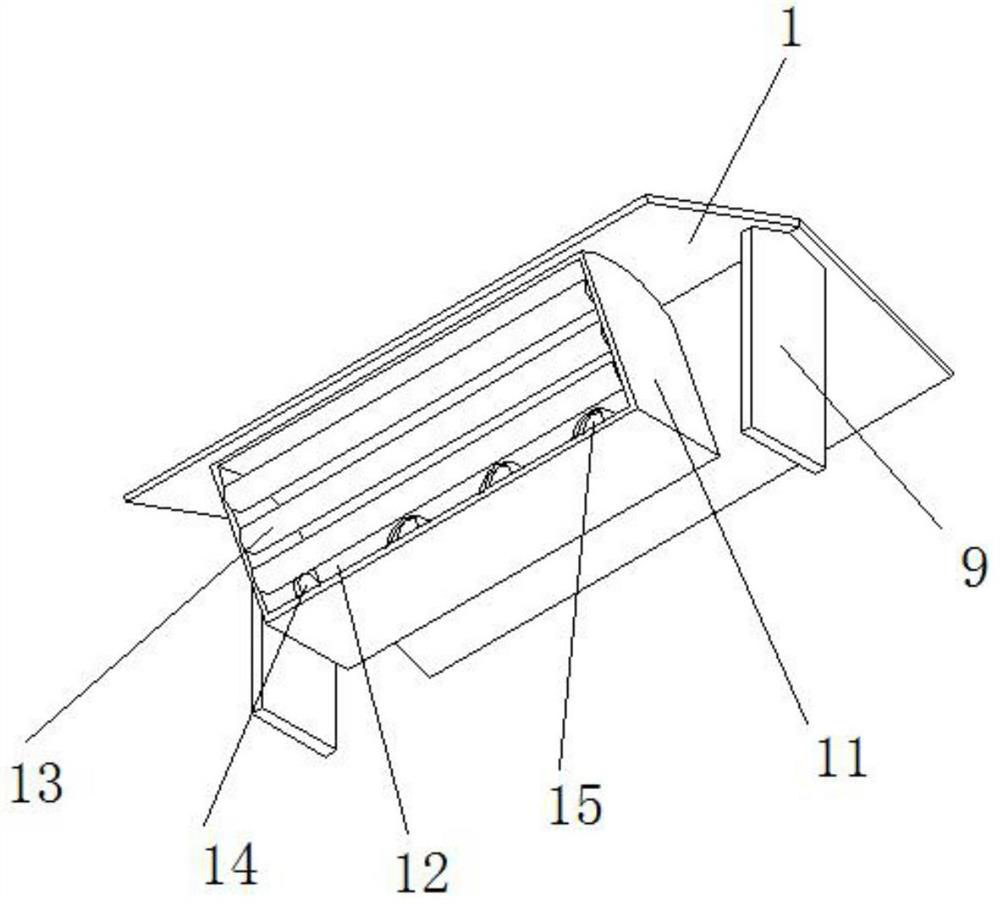

[0025] refer to Figure 1-4 As shown, an engineering lighting lamp with a remote monitoring system includes a lighting mechanism 2, a controller 4, a moving mechanism 6, an adjusting mechanism 7, and a cooling mechanism 15. The lighting mechanism 2 is composed of a mounting plate 8 and a mounting block 11. Block 11 is welded on the top of mounting plate 8, mounting block 11 side outer wall is provided with mounting groove 12, mounting groove 12 both sides inner walls are equipped with lighting tubes 13 equidistantly distributed, cooling mechanism 15 is composed of cooling fan 16, cooling box 17, The semiconductor refrigerating sheet 18 and the heat dissipation pipe 19 are formed, and the inner wall on one side of the installation groove 12 is provided with installation openings distributed equidistantly. The cooling fan 16 is installed on the inner wall of the installation opening. The side outer wall is provided with equidistantly distributed connecting ports, the semiconduct...

Embodiment 2

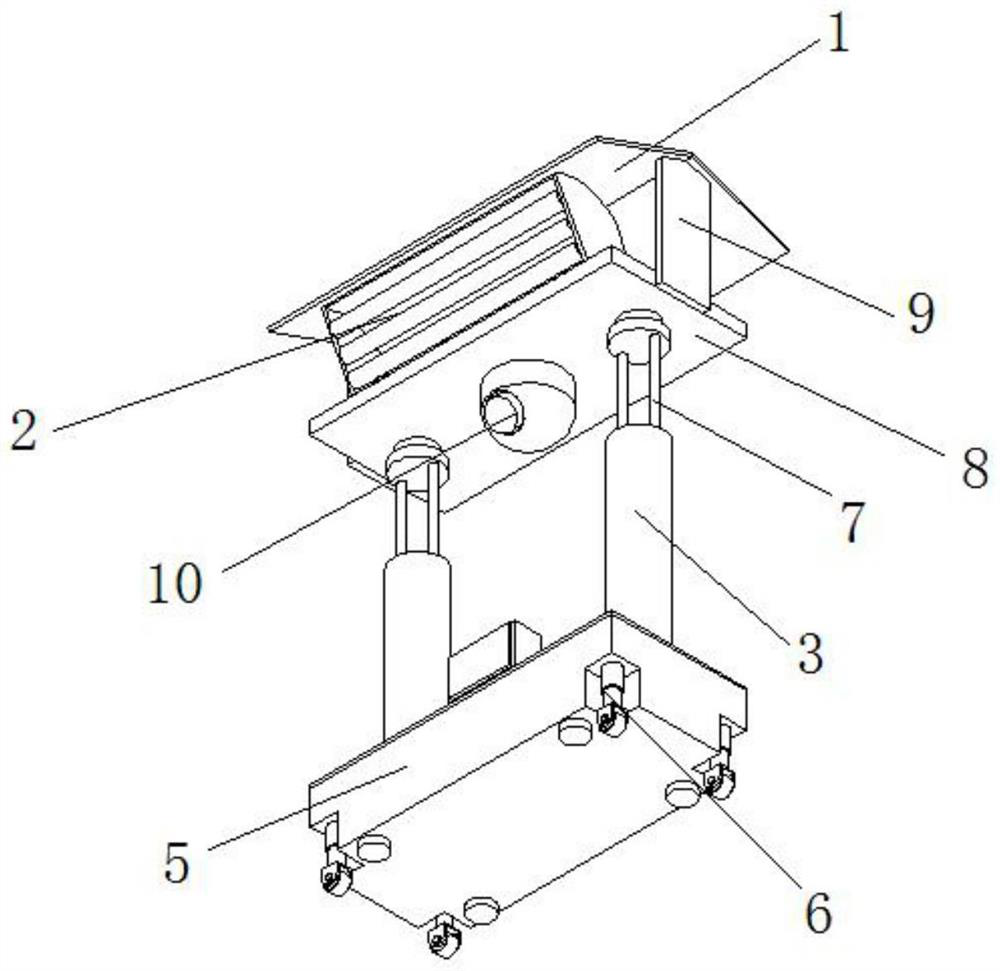

[0027] refer to Figure 5-6 As shown, the adjustment mechanism 7 is composed of a counterweight 5, a bearing 21, a threaded rod 24, a low-speed motor 25 and a fixing ring 28. Both ends of the top of the counterweight 5 are provided with fixing grooves 27, and the low-speed motor 25 is welded to the fixing groove 27. The inner wall of the bottom, the threaded rod 24 is connected to the output end of the low-speed motor 25, the fixing ring 28 is screwed to the outer wall of the threaded rod 24, the two ends of the top of the fixing ring 28 are welded with guide rods 23, the top of the guide rod 23 is welded with a top plate 22, and the bearing 21 It is welded to the top of the top plate 22, and the top of the bearing 21 is welded to the bottom of the mounting plate 8. A cover plate 26 is installed on the top of the counterweight 5, and two guide tubes 3 are welded on the top of the cover plate 26. The guide tube 3 and the outer wall of the fixed ring 28 form Slip fit.

Embodiment 3

[0029] refer to Figure 7 As shown, the moving mechanism 6 is composed of an electric push rod 30 and a universal wheel 21. The four corners of the bottom of the counterweight 5 are provided with connecting grooves 29, the electric push rod 30 is welded to the inner wall of the top of the connecting groove 29, and the universal wheel 21 is welded to the electric The bottom of the push rod 30, the four corners of the bottom of the counterweight 5 are bonded with rubber contact blocks 32, the outer walls of both sides of the mounting plate 8 are welded with a vertical plate 9, and the top of the vertical plate 9 is welded with a rain shelter 1, the lighting mechanism 2, the mobile The mechanism 6, the regulating mechanism 7, the monitor 10 and the cooling mechanism 15 are all connected to the output end of the controller 4 through wires, and the controller 4 is connected to the power line.

[0030] Through the operation of the low-speed motor 25 arranged inside the fixing groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com