A rock test sample cutting device and cutting method in a fidelity environment

A rock test and cutting device technology, applied in the preparation of test samples, measuring devices, sampling, etc., can solve the problems of low processing efficiency, less available quantity, and core distortion, so as to reduce the scrap rate and avoid pollution damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

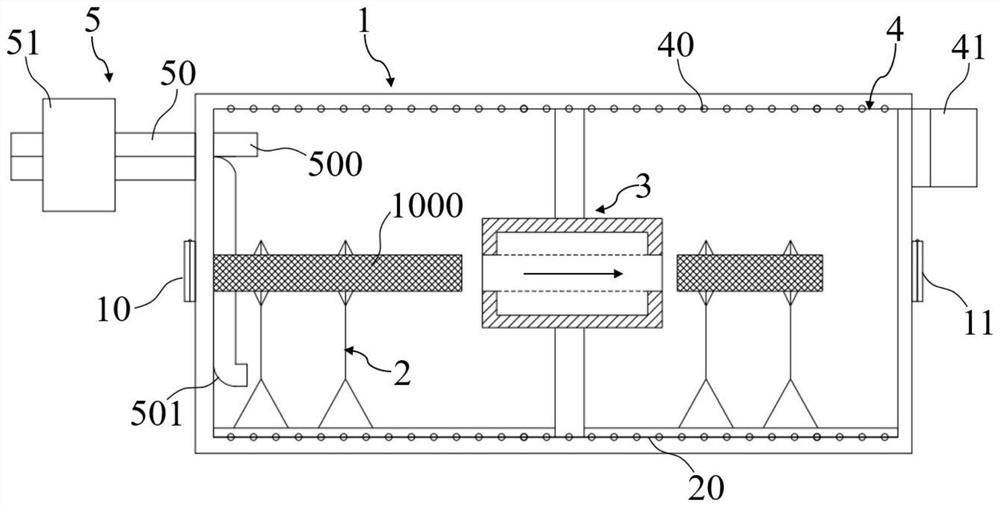

[0060] The rock test sample cutting device under the fidelity environment of this embodiment includes:

[0061] The fidelity cabin 1 is a closed structure, and the left and right ends are respectively provided with a feeding port 10 and a discharging port 11;

[0062] The displacement unit 2 is arranged in the fidelity cabin 1 and transports the core 1000 in the fidelity cabin 1;

[0063] The cutting unit 3, which is arranged in the fidelity cabin 1, cuts the core 1000;

[0064] The temperature control unit 4, which is connected to the fidelity cabin 1, controls the temperature in the fidelity cabin 1;

[0065] The pressurizing unit 5, which is connected to the fidelity cabin 1, controls the pressure in the fidelity cabin 1.

[0066] like figure 1 As shown in the figure, the fidelity chamber 1 of this embodiment is in the shape of a hollow cylinder, and a feeding port 10 and a discharging port 11 are respectively formed on both ends of the fidelity chamber 1, which are respec...

Embodiment 2

[0070] The rock test sample cutting device in the fidelity environment of this embodiment is further improved on the basis of Embodiment 1, and the displacement unit 2 includes:

[0071] The track 20 is laid on the bottom of the fidelity capsule 1 along the length direction of the fidelity capsule 1;

[0072] One end of the manipulator is slidably connected to the track 20, and the other end holds the core 1000.

[0073] like figure 1 As shown, in this embodiment, there are three manipulators, one manipulator, No. 2 manipulator and No. 3 manipulator from left to right, wherein the No. 1 manipulator and No. 2 manipulator are located on the left side of the cutting unit 3, close to the feeding Port 10, the No. 1 manipulator and No. 2 manipulator are separated by 30cm, which are used to hold and move the core 1000 to be cut. The No. 3 manipulator is located on the right side of the cutting unit 3, close to the discharge port 11, used for holding and transporting after cutting r...

Embodiment 3

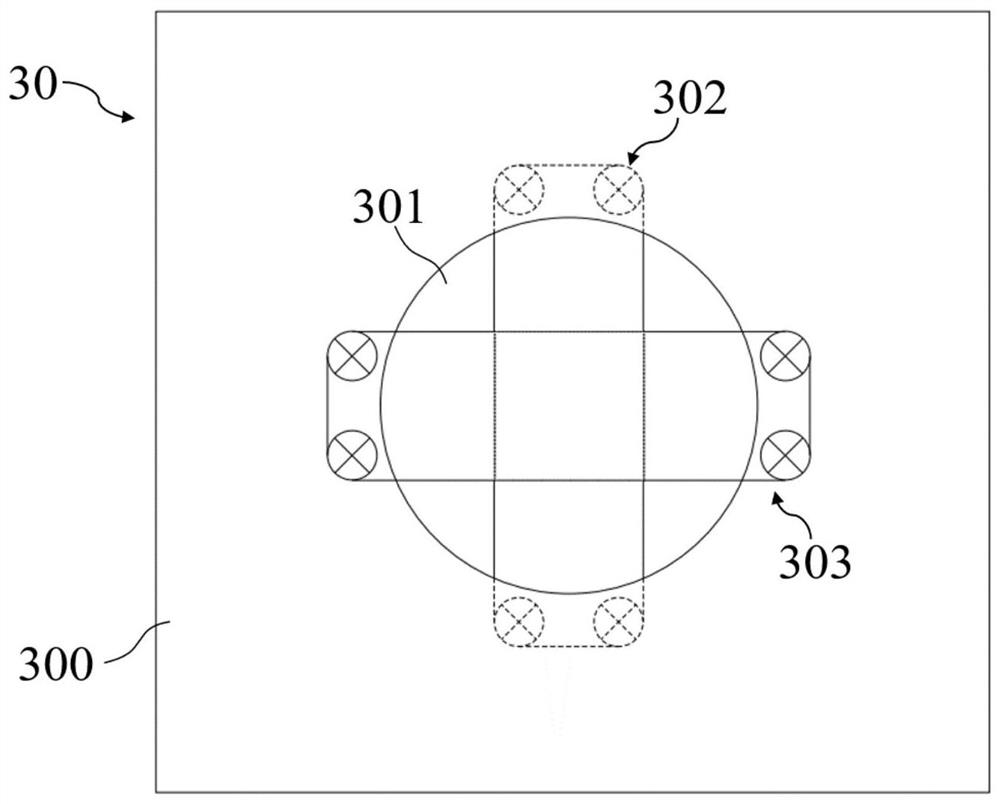

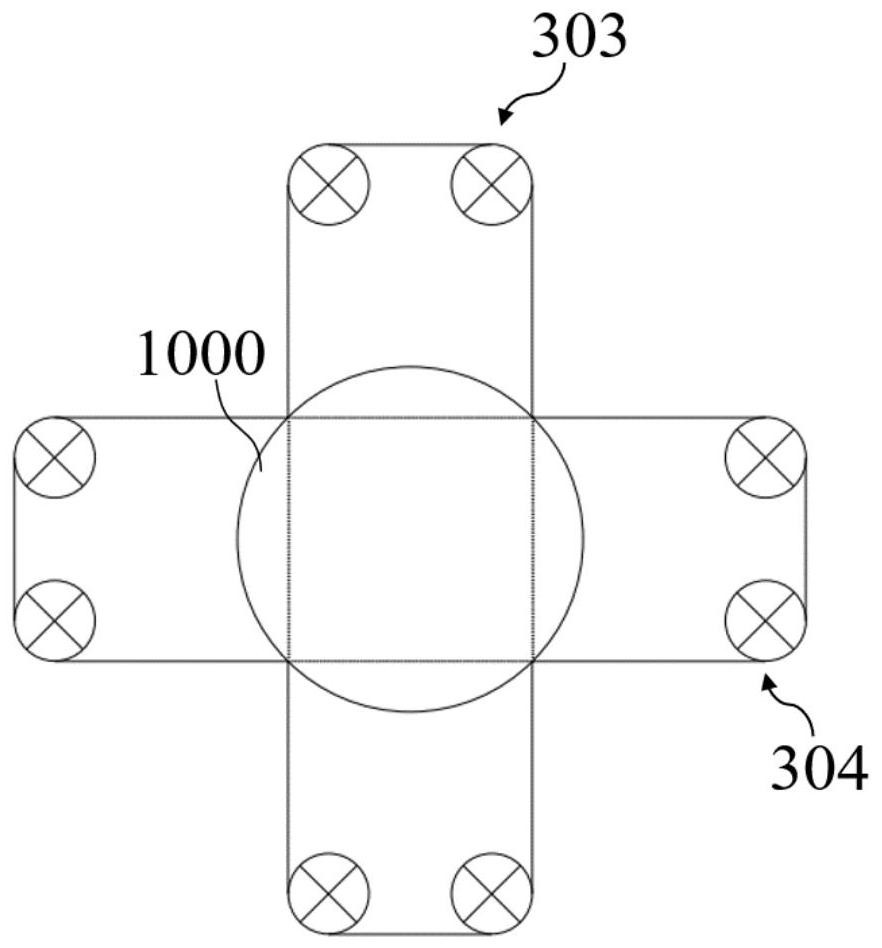

[0075] The rock test sample cutting device in the fidelity environment of this embodiment is further improved on the basis of Embodiment 2. The cutting unit 3 includes a square cutting part 30, which includes:

[0076] Mounting seat one 300, which is movably connected with the inner wall of the fidelity cabin 1;

[0077] A sample port one 301, which runs through the mounting seat one 300, for the core 1000 to pass through;

[0078] The longitudinal cutting member 302 includes four driving wheels and an emery wire, the driving wheels are distributed on the upper and lower sides of the sample port one 301 in two, and the emery wire surrounds each driving wheel to form a longitudinal rectangle in the longitudinal direction;

[0079] The transverse cutting member 303 also includes four driving wheels and a diamond wire. The driving wheels are distributed on the left and right sides of the sample port 1 301. The diamond wire surrounds each driving wheel to form a rectangle whose le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com