Reducing clamp for damping bushing

A diameter reducing and clamping technology, which is applied in the field of reducing clamps for shock absorbing bushes, can solve the problems of large or small size, low pass rate, poor appearance quality, etc., and achieve the effect of avoiding small size and increasing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

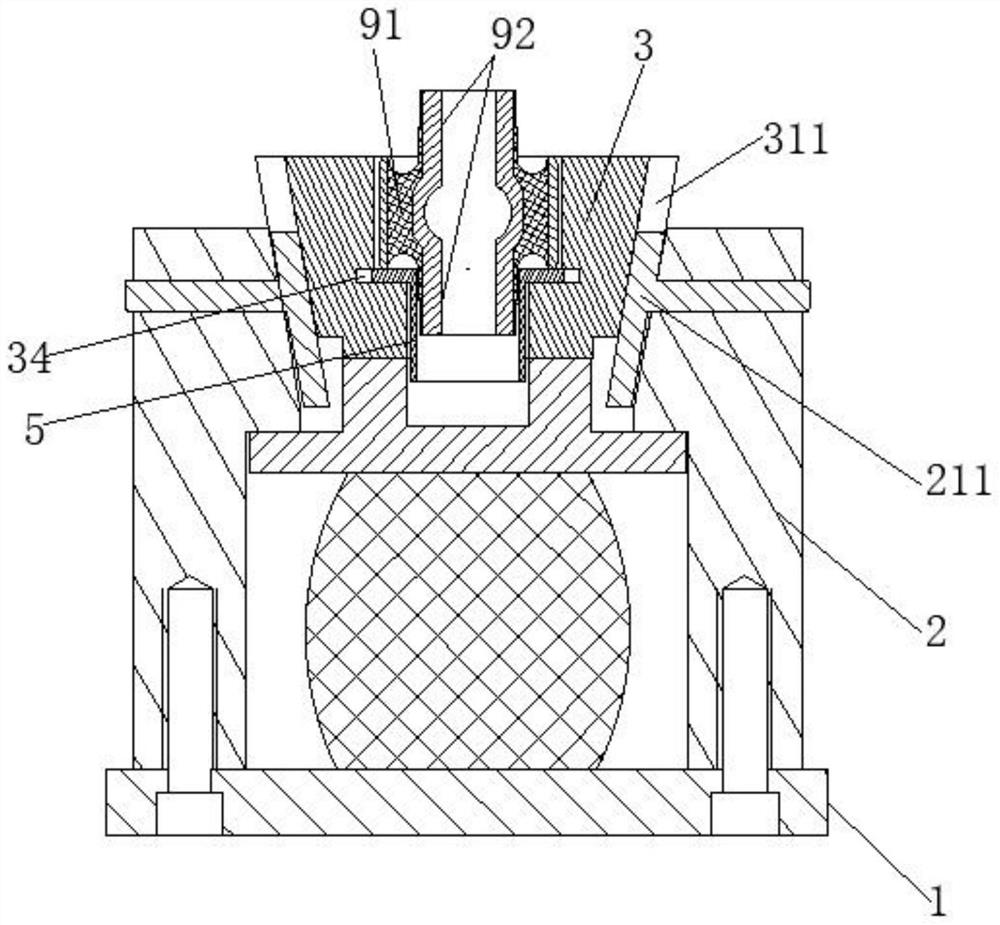

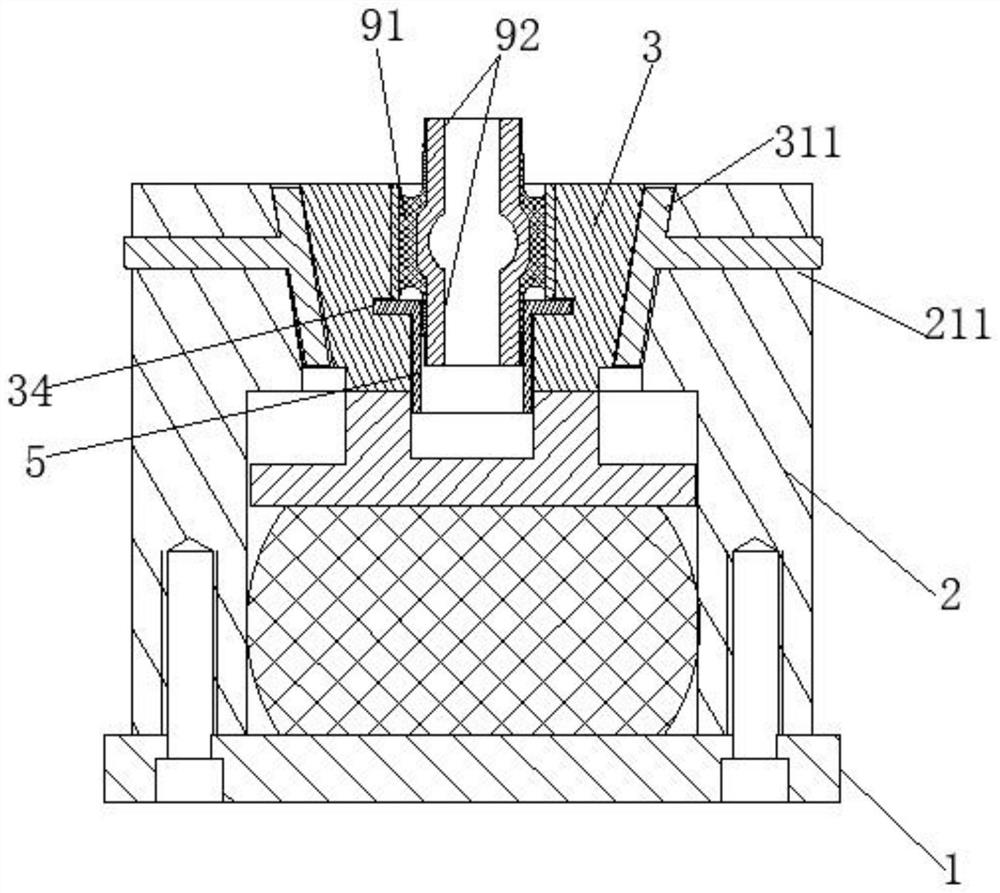

[0029] like Figure 1 - Figure 7 As shown in this embodiment, the damping bush jig with a reduced diameter, for the liner is reduced in diameter, the liner comprising a reduced diameter section 91 and the non-reduced diameter section 92, the reduced diameter section 92 is located non-condensing diameter section 91 at both ends, comprises a base 1, a clamp 2, 3 and a plurality of Hough ram; the clamp 2 is fixed to the base 1, the clamp 2 is arranged in a cylindrical shape, arranged for placement intermediate Hough 3 of shrinkage holes 21, shrinkage of the inclined inner wall provided with a hole 21, and the diameter is gradually reduced from top down; Huff inclined outer wall portion 21 of the inner wall 3 is provided with a shrink fit hole 31, the Hough the inner wall 3 is arranged sequentially from top to bottom reduced-diameter portion 32 and a stopper portion 33; a plurality of annular arrays Hough 3 distributed within the shrinkage holes 21, a plurality of the inclined portion ...

Embodiment 2

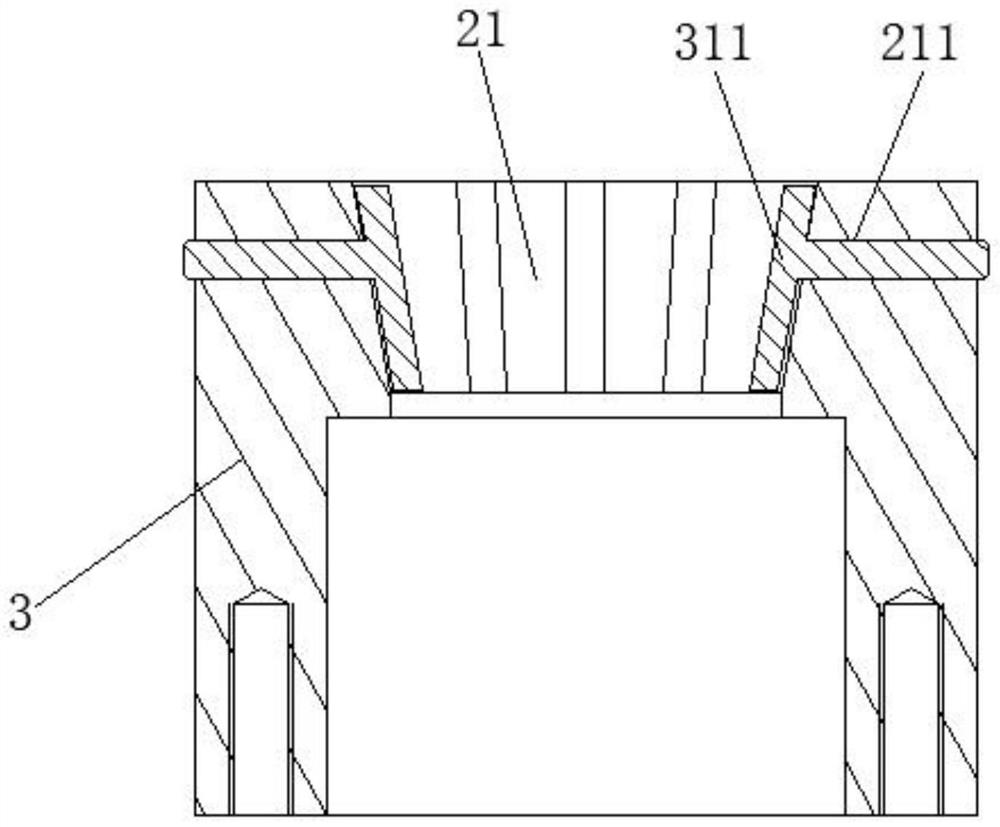

[0037] like Figure 7 , Figure 8As shown, the present embodiment is replaced with the restricted ring 51 of the outer wall of the limit element 5 to the limit column 52 compared to the first embodiment, and the limit slot 34 used in combination with the limit ring 51 is replaced with the limit column. 52 mating column slot 35.

[0038] By setting the finite casing 52 in the outer wall of the limit member 5, the limit seat member 5 is a ring array distribution; a column groove 35 that cooperates with the limit column 52 by the inner wall of the Haf 3; in the diameter, columnar The groove 35 slides along the limit position 52, and several Haf 3 maintain the same lower speed in the vertical direction, so that the diazilizing speed of several Haf 3 is always equal, and the minimum number of column 52 is performed on the tangent Limited, the Kaf 3 is only axially displaced along the limit column 52.

[0039] The limit post 52 is inclined in the horizontal direction; the horizontal heigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com