Pre-assembly clamp for automobile welding production

A pre-assembly, automotive technology, applied in auxiliary devices, manufacturing tools, welding equipment, etc., can solve the problems of affecting parts welding, large parts errors, parts not in the same horizontal position, etc., to improve welding accuracy, reduce Adjust the difficulty and save the effect of manual adjustment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

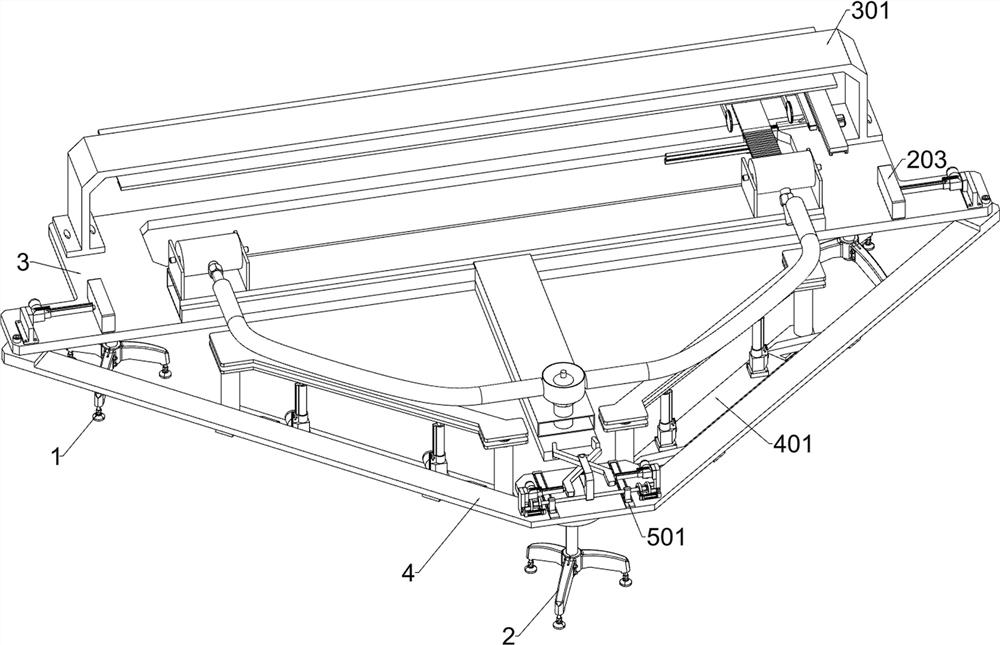

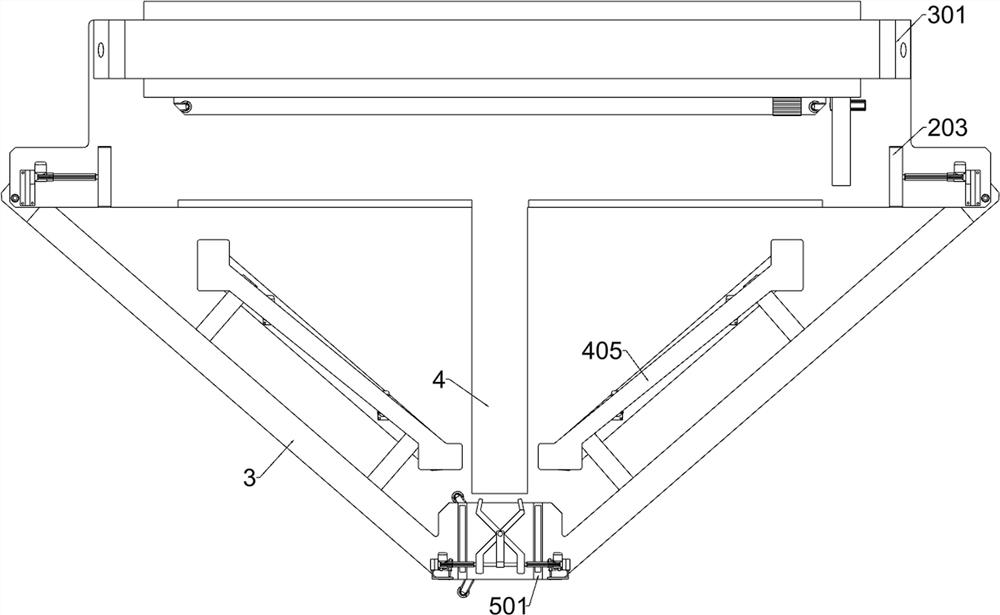

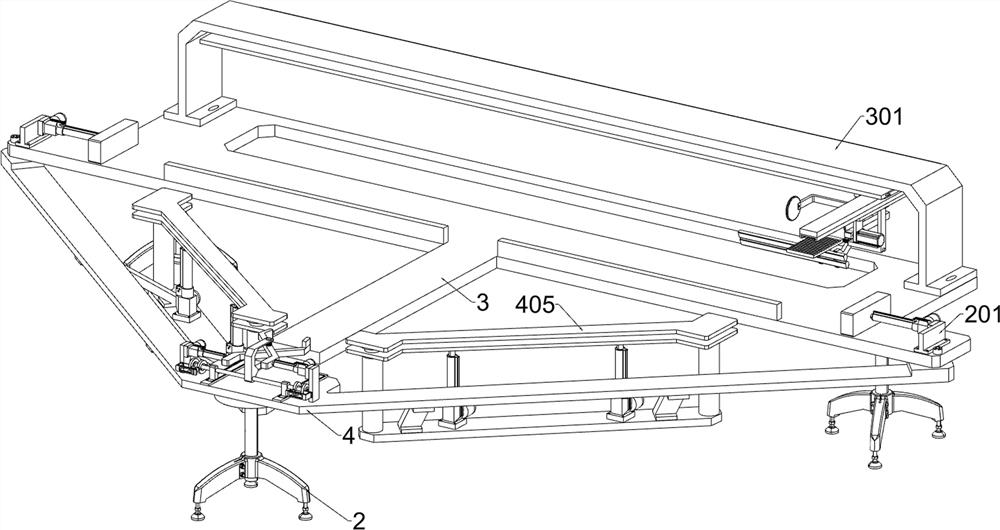

[0032] A pre-assembled fixture for automobile welding production, such as Figure 1-11 As shown, it includes a first foot 1, a second foot 2, a mounting plate 3, a V-shaped mounting plate 4, a positioning unit, an adjustment fixing unit and a height fixing unit; the first foot 1 is provided with two , the two first footings 1 are respectively located on the left and right sides of the lower surface of the mounting plate 3; the upper surface of the second footing 2 is welded with a V-shaped mounting plate 4; the front side of the mounting plate 3 is bolted to the V-shaped mounting plate 4; a positioning unit is installed on the front side of the upper surface of the installation and placement plate 3; an adjustment and fixing unit is installed on the rear side of the upper surface of the installation and placement plate 3; height-fixing units are installed on the left and right sides of the V-shaped installation plate 4.

[0033]The positioning unit includes a first connecting ...

Embodiment 2

[0044] On the basis of Example 1, such as figure 1 , Figure 12-13 As shown, a fine-tuning fixing unit is also included, and the middle part of the upper surface of the V-shaped mounting plate 4 is equipped with a fine-tuning fixing unit. 504, the fifth connecting plate 505, the seventh driving member 506, the clamping plate 507, the third connecting frame 508, the first connecting column 509, the second connecting column 5010, the fixed ring 5011, the fourth sliding rail 5012 and the eighth Drive member 5013; two symmetrical third slide rails 501 are installed in the middle of the upper surface of the V-shaped mounting plate 4; a sixth drive member 502 is slidingly connected within the two third slide rails 501; two sixth drive members 502 The upper side is penetrated and fixed with a second connecting rod 503; the outer surface of the second connecting rod 503 is equipped with two left and right symmetrical microrotators 504; the middle part of the outer surface of the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com