A stamping equipment for the production of generator stator steel sheets

A technology of generator stator and stamping equipment, applied in the field of stamping equipment, can solve the problem of not having the function of positioning the steel sheet of the generator stator, and achieve the effects of convenient replacement, improved processing accuracy and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

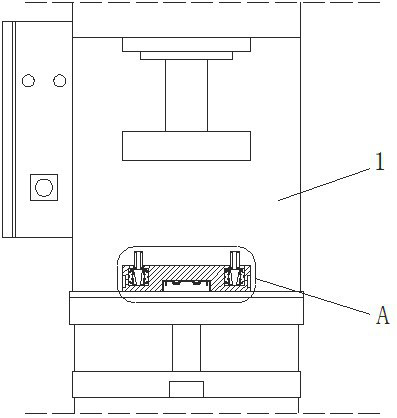

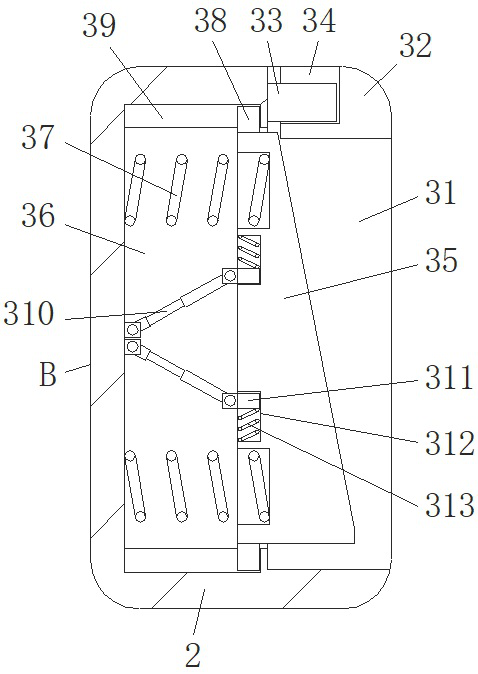

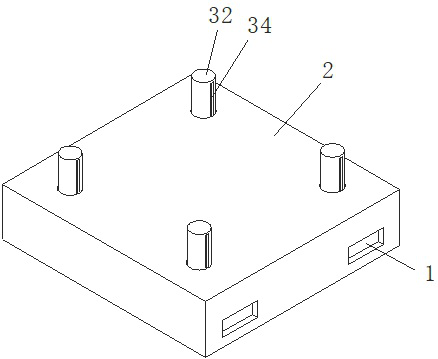

[0025] see Figure 1-5 As shown, a stamping equipment for the production of generator stator steel sheets includes a main body 1 and a stamping table 2; the main body 1 of the equipment is provided with a stamping table 2, and a positioning mechanism is provided inside the stamping table 2; The positioning mechanism includes a storage chamber 31, a positioning column 32, a limit assembly, an abutment block 35, a movable chamber 36, a return spring 37, a sliding assembly and an auxiliary reset assembly. The positioning column 32 is sleeved inside the storage cavity 31 , the limiting components are arranged on both sides of the positioning column 32 , one side of the abutment block 35 is arranged inside the storage cavity 31 , and the abutment block 35 The other side of the spring is sleeved inside the movable cavity 36, and the movable cavity 36 is provided on both sides of the storage cavity 31. The side of the return spring 37 close to the abutting block 35 is fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com