Counter-force device for testing tension sensor

A technology of tension sensor and counter force device, which is applied in measuring devices, calibration/testing of force/torque/power measuring instruments, instruments, etc., can solve the problems of heavy weight, difficulty in sensor detection, inability to directly detect tension sensor, etc., to achieve The effect of improving precision and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

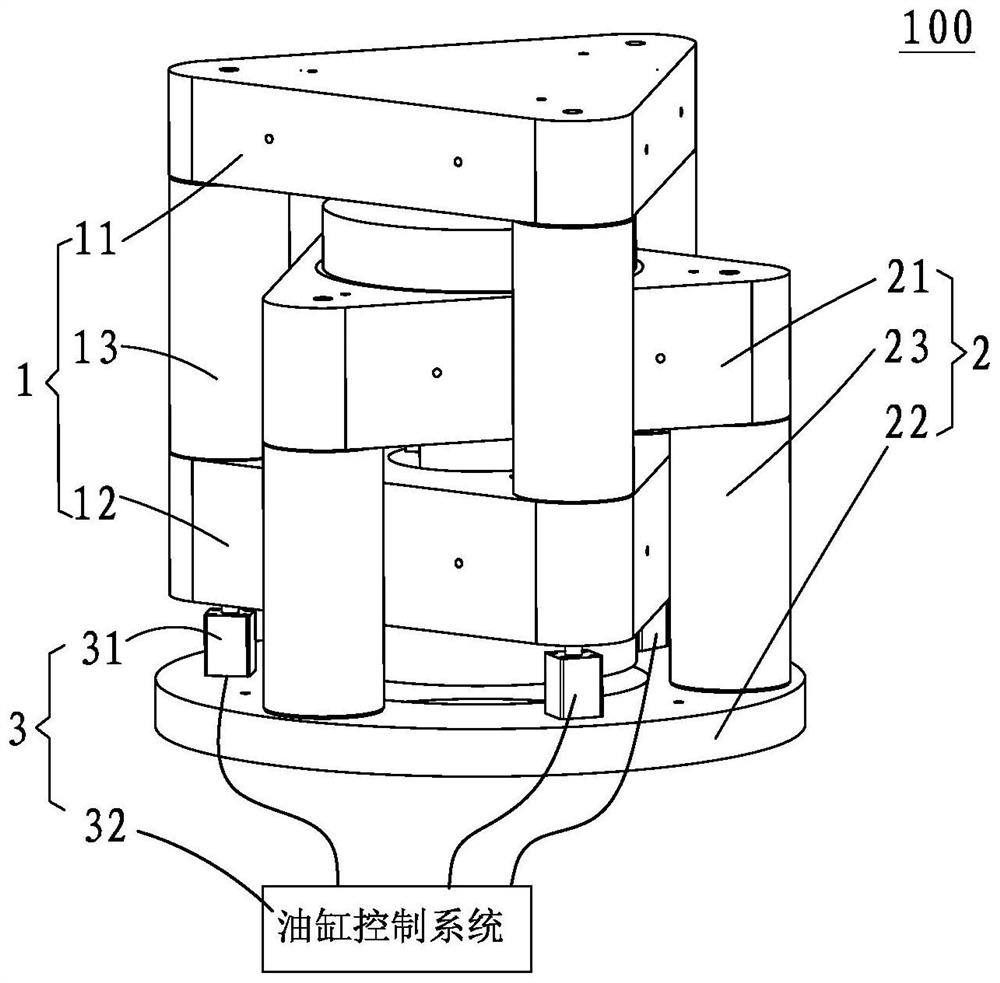

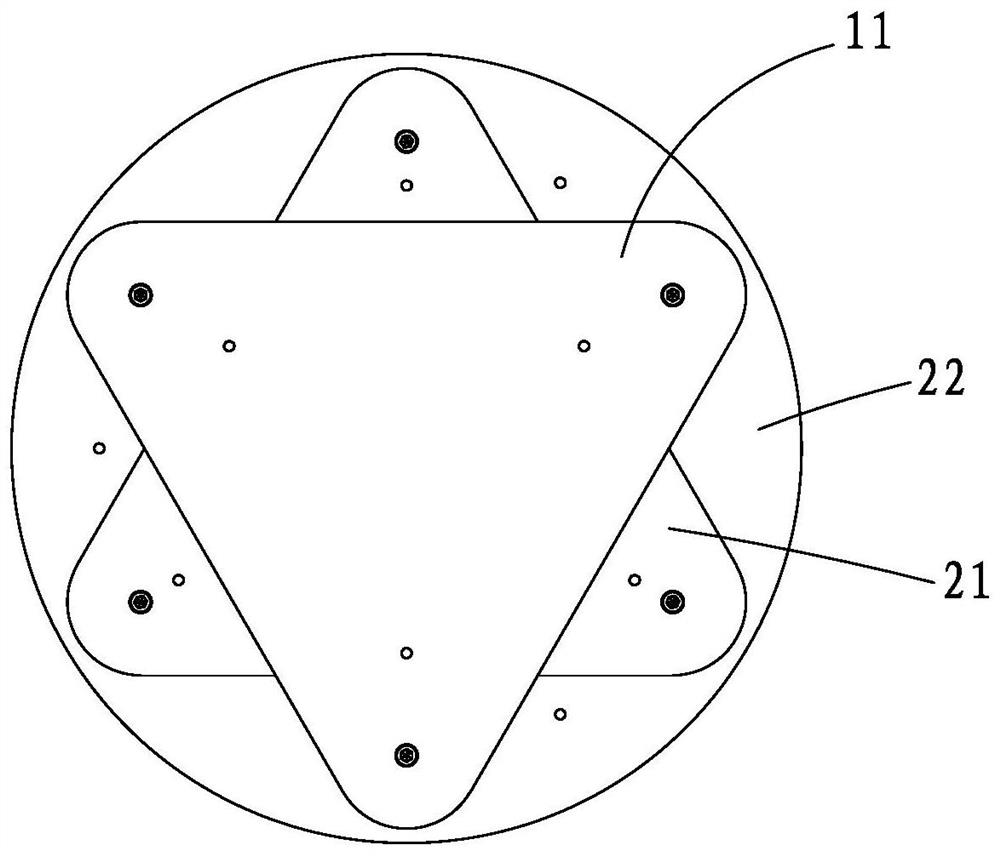

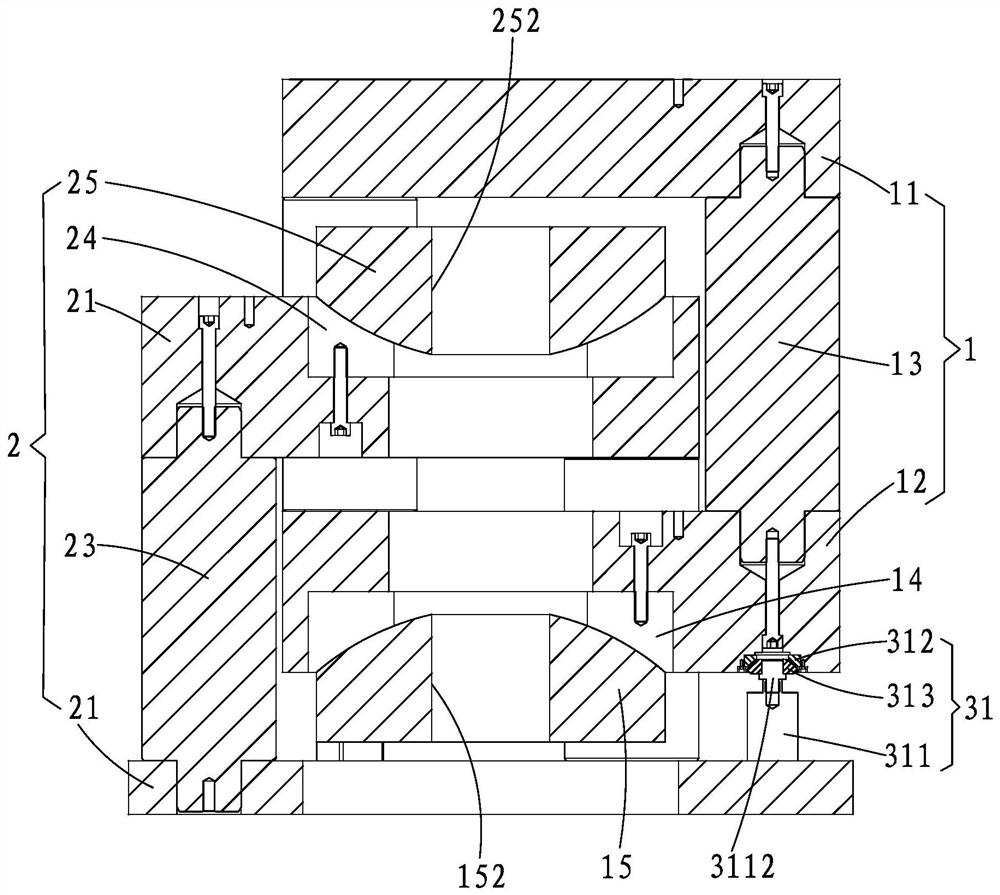

[0019] The embodiment of the present invention provides a counter force device for testing the tension sensor, which can convert the compressive force into the tensile force, and ensure that the direction and magnitude of the force are consistent.

[0020] The technical solution in the embodiments of the present invention is to solve the above problems, the general idea is as follows: the pressure of the pressure testing machine is converted into tension by designing the counter force device, so that the tension test of the tension sensor can be realized through the pressure testing machine. The reaction force device is equipped with lower brackets and upper brackets arranged in a staggered manner. Place the bottom plate of the lower bracket centered on the working platform of the force standard machine or fatigue testing machine, and apply pressure to the top plate of the upper bracket. The upper bracket has an overall downward movement. Trend, because the lower bracket does n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com