Flexible flat cable fitting device and fitting method based on Internet of Things

A technology of flexible wiring and laminating devices, which is applied in the direction of assembling printed circuits with electrical components, electrical components, and printed circuit manufacturing. , to achieve the effect of not easy to deviate and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

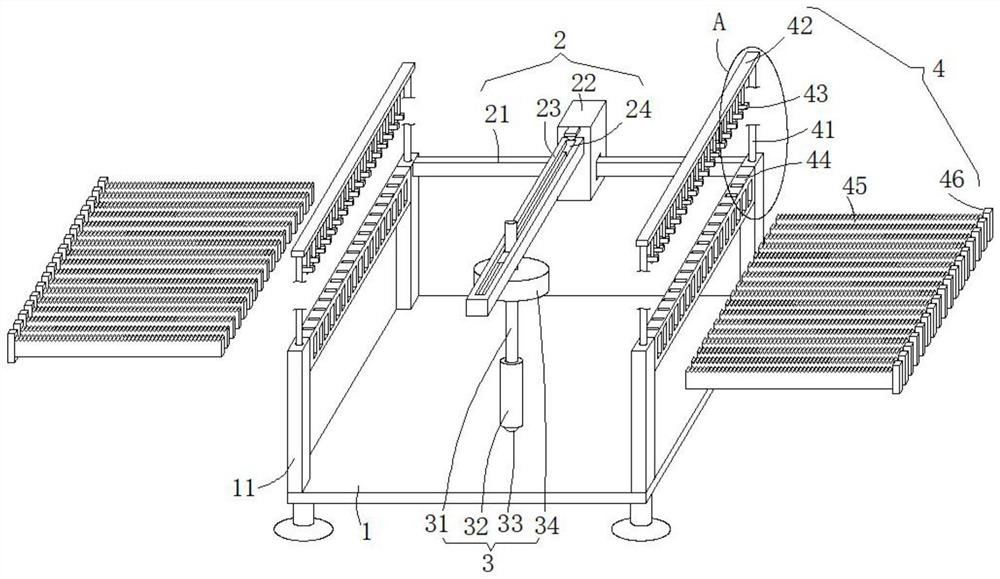

[0030] see Figure 1-3 , this embodiment provides a flexible cable lamination device and lamination method based on the Internet of Things, including a base 1, an adjustment mechanism 2 and a lamination mechanism 3, and the four corners of the upper end of the base 1 are vertically fixed with support columns 11. The adjustment mechanism 2 includes a crossbeam 21, and the axial ends of the crossbeam 21 are fixedly connected to the top positions of the two rear support columns 11 opposite to the side walls. The adjustment mechanism 2 adjusts the position of the fitting mechanism 3 to achieve the purpose of precisely fitting the flexible circuit board.

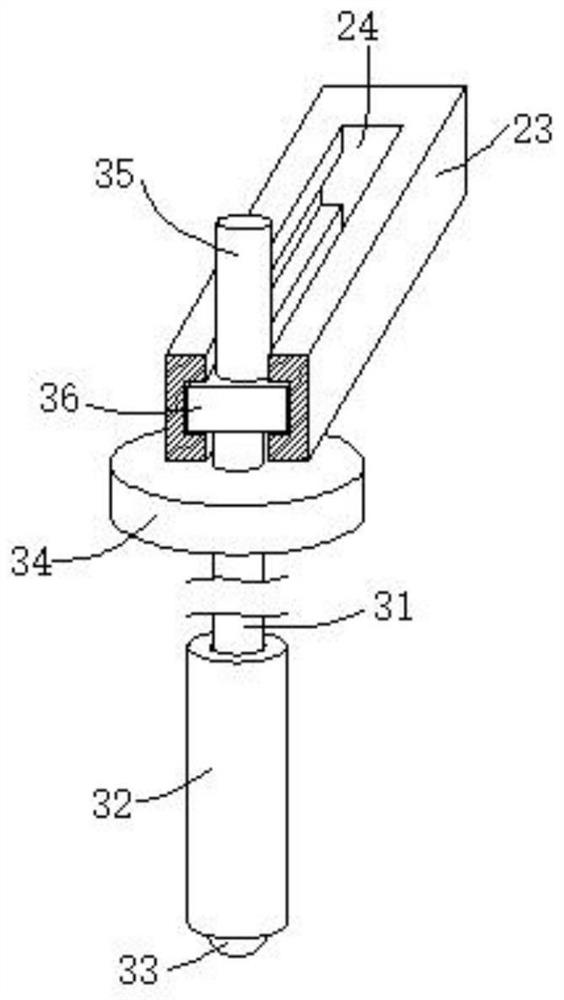

[0031] An adjustment seat 22 is slid on the crossbeam 21, and the top position of the front end of the adjustment seat 22 is hinged with an adjustment hoisting plate 23. The adjustment seat 22 can drive the adjustment hoisting plate 23 to freely adjust its position along the horizontal direction of the beam 21. The hinge with th...

Embodiment 2

[0038] see Figure 1-3 , made further improvement on the basis of embodiment 1:

[0039] In order to adjust the position of the fitting mechanism 3 with bare hands, a handle 35 that slides through the opening above the adjustment hole 24 is vertically fixed on the upper end of the rectangular slider 36. Holding the handle 35 with bare hands is convenient for applying force, and the rectangular slider can be slid along the adjustment hole 24. The block 36 uses the freely sliding rectangular slider 36 to drive the whole fitting mechanism 3 to slide and adjust the fitting position.

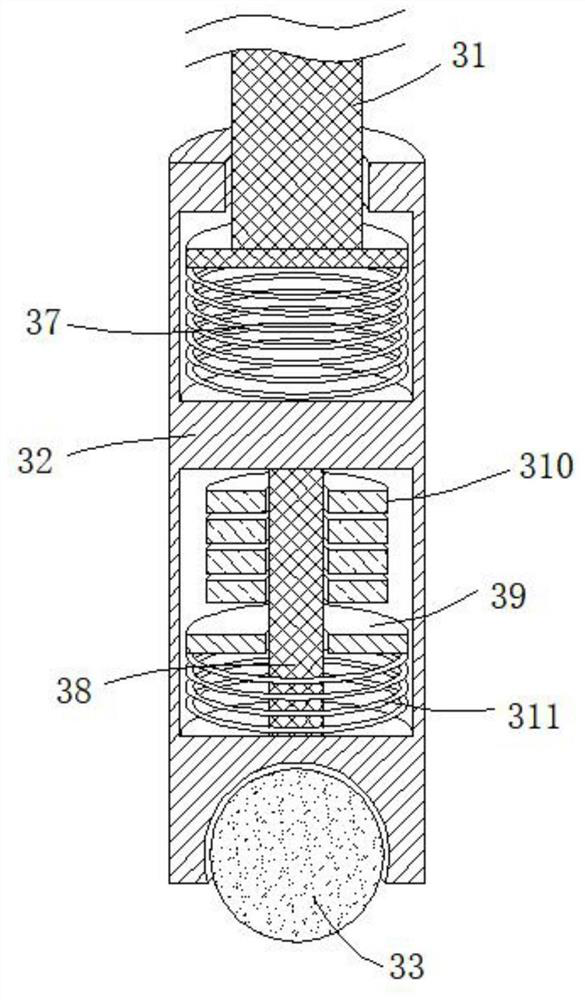

[0040] In order to improve the compactness of the iron pressing ball 33 when rolling and bonding, a buffer cavity located above the iron pressing ball 33 is provided inside the hoisting column 32. A slide bar 38 is fixedly installed, and the outer wall of the slide bar 38 is slidingly sleeved with a support plate 39 that can slide up and down according to the interior of the buffer cavity. The suppo...

Embodiment 3

[0044] see figure 1 and Figure 4 , made further improvement on the basis of embodiment 2:

[0045] The bonding mechanism 3 can be adjusted at any position on the upper end of the base 1, and it is impossible to carry out the rolling bonding operation according to the specific wiring position of the flexible circuit board. The guide plate 34 with the lower opening is provided with a guide mechanism 4 that can be used to limit the running track of the guide plate 34 between the two support columns 11 distributed front and back, and the guide mechanism 4 located on both sides of the guide plate 34 is used to limit the operation of the guide plate 34 track, so as to determine the position of the bonding mechanism 3 according to the wiring track of the flexible circuit board, so as to facilitate the precise rolling and bonding operation, and it is not easy to deviate.

[0046] The guide mechanism 4 includes an installation backing plate 44, and the front and rear ends of the ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com