Jig saw

A curve saw and body technology, applied in the field of curve saws, can solve problems such as the breakage of the bottom plate and the gearbox, achieve simple and fast adjustment methods, and prevent the effect of breaking and falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

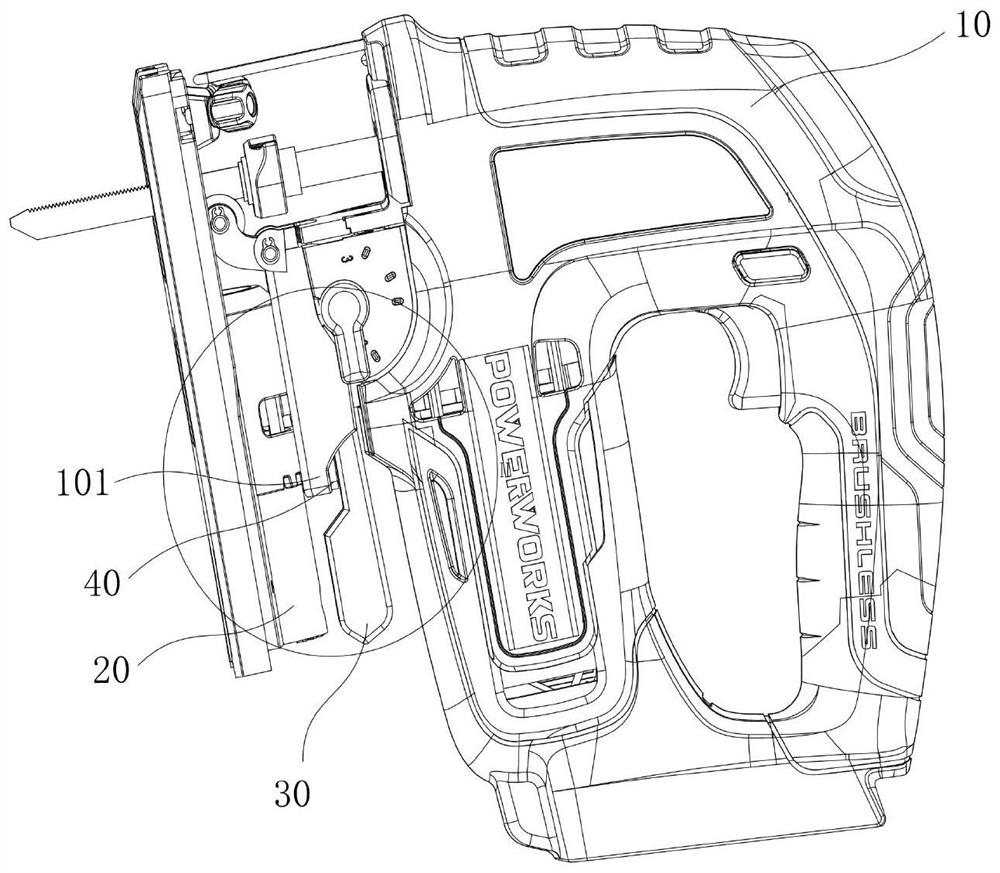

[0036] see figure 1 , the present invention provides a jigsaw, comprising: a jigsaw body 10, a base plate 20, the base plate 20 is connected to the jigsaw body 10; The tension of the connection between the adjusting rod 30 and the base plate 20 ;

[0037] Specifically, when the jigsaw is performing a cutting operation, the gear box inside the jigsaw body 10 will drive the saw blade to reciprocate, thereby enabling the jigsaw to have a cutting function. When the jigsaw is performing a cutting operation, the bottom plate 20 can enable the jigsaw to Attached to the material being cut, it assists the jigsaw in cutting operations and improves the stability of the jigsaw during cutting.

[0038] Furthermore, the jigsaw body 10 is connected to the bottom plate 20 through the adjustment rod 30, and by rotating the adjustment rod 30, a small gap can be formed between the bottom plate 20 and the adjustment rod 30, and at this time, the bottom plate 20 can be driven to adjust the angle....

Embodiment 2

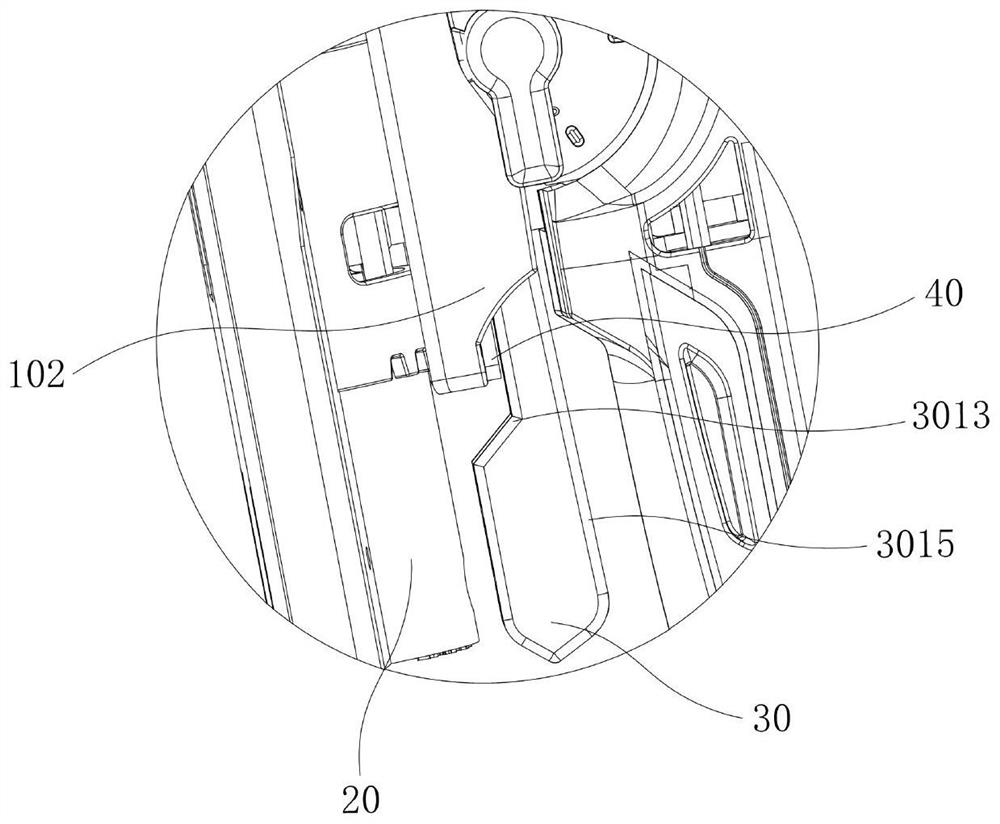

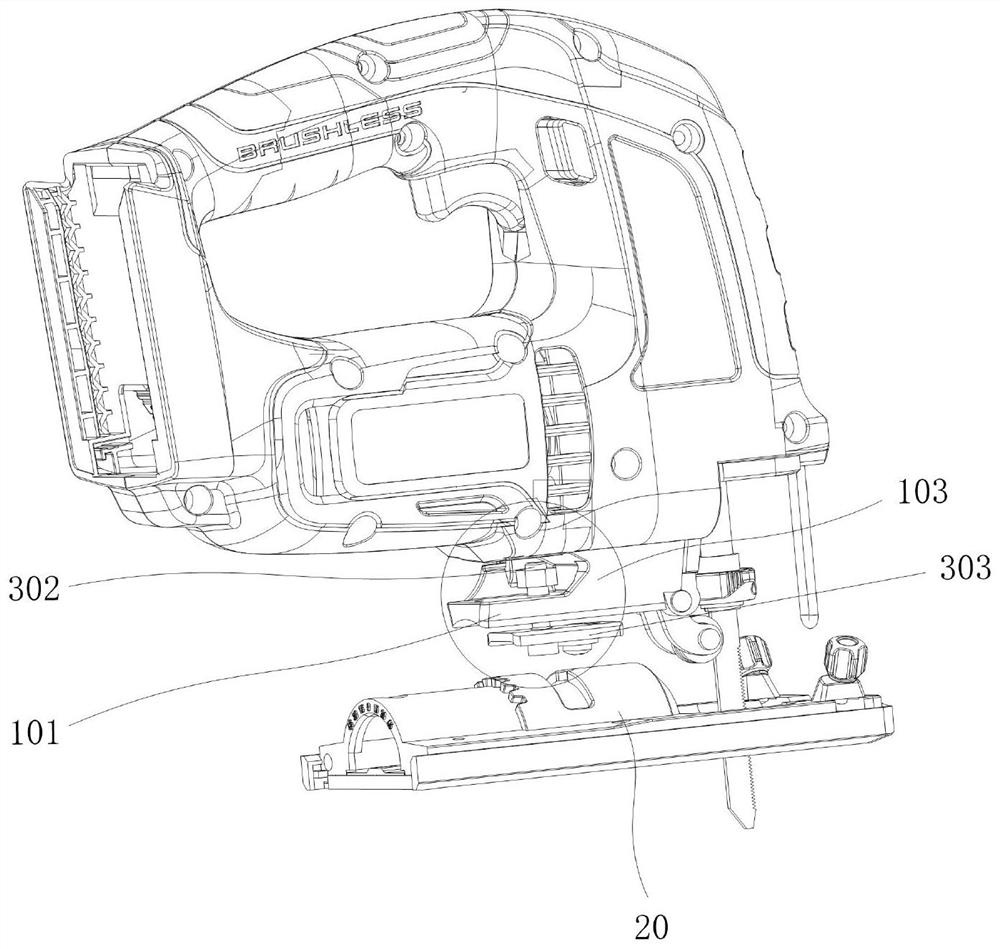

[0042] see Figure 1 to Figure 4 , the adjusting rod 30 includes: an adjusting handle 301, and the adjusting handle 301 is provided with a first through hole 3016;

[0043]Wherein, the first through hole 3016 provided at the end of the adjusting handle 301 is connected with the nut provided on the connecting rod 302, and generally cannot be disassembled, and the hexagonal structure of the nut can make the adjusting handle 301 and the connecting rod 302 The connection stability is high enough, and the strength is high enough. At the same time, the connecting rod 302 can be rotated, lifted or lowered. The engaging plate 303 is closely attached to the bottom plate 20 during use, and the tightness between the engaging plate 303 and the bottom plate 20 Fitting can prevent the bottom plate 20 from loosening or falling off during use.

[0044] Specifically, when it is necessary to adjust the angle of use of the base plate 20, since the engaging plate 303 and the base plate 20 are in...

Embodiment 3

[0046] see Figure 3 to Figure 4 , the jigsaw body 10 includes: a connection plane 101, the connection plane 101 is provided with a second through hole 1011, the second through hole 1011 can pass through the connecting rod 302; the first baffle plate 102, the first baffle plate 102 and the connection plane 101 connected, and the space formed by the first baffle plate 102 and the outside defines the rotation range of the adjustment handle 301 .

[0047] Wherein, the connection plane 101 is a part of the jigsaw body 10, specifically, the connection plane 101 is a part of the gear box, and at the same viewing angle, if the first baffle plate 102 is arranged on the left side of the connection plane 101, it can limit Adjust the angle of rotation of the handle 301 clockwise. On the contrary, if the first baffle plate 102 is arranged on the right side of the connection plane 101, it can limit the angle of rotation of the adjustment handle 301 counterclockwise, preventing the rotation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com