Electro-gas welding method for 42-50 mm high-strength steel plate for ship body

A gas-electric vertical welding, high-strength steel plate technology, applied in arc welding equipment, welding equipment, welding accessories and other directions, can solve the problems of difficult preheating, difficult operation, poor appearance quality of welds, etc., to shorten the welding cycle, The effect of improving weld quality and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

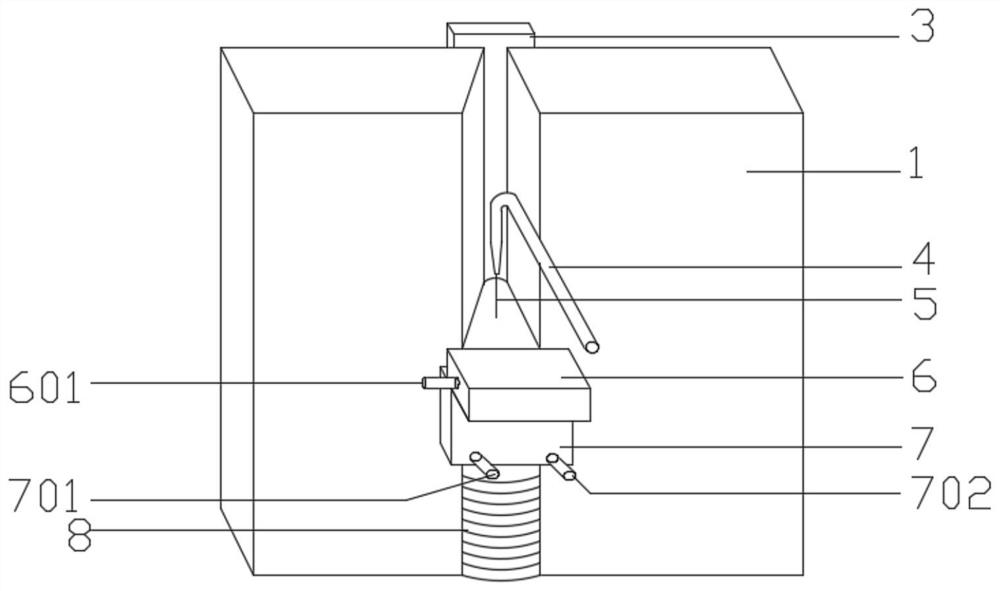

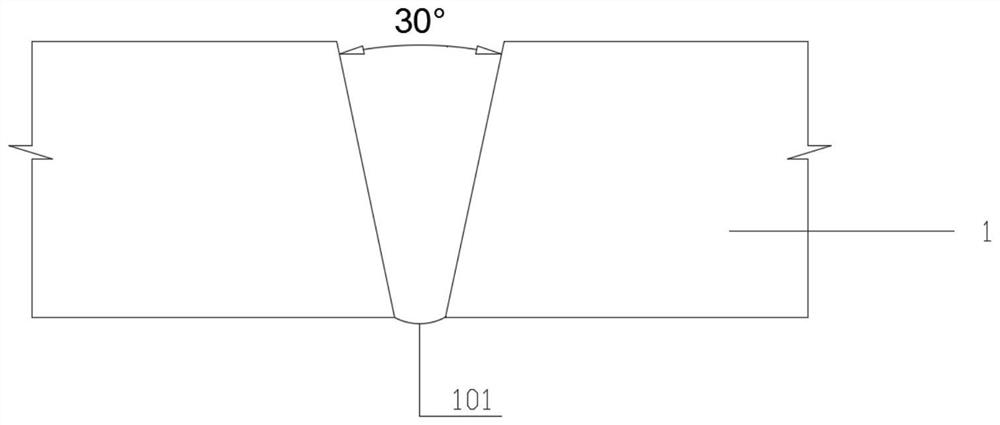

[0026] Such as Figure 1 to Figure 3 As shown, a gas-electric vertical welding method for high-strength steel plates for a 49mm hull includes the following specific steps:

[0027] (1) Set the groove with the test plate, the test plate is made of high-strength steel EH36 for the hull, the thickness is 49mm, the required value of the tensile strength is 490-630 (MPa), the impact energy AKV≥34J at the welded joint -20 ℃, the test piece The specification is 1500mm (length) × 400mm (width) × 49mm (thickness), the welding groove type adopts single-sided V-shaped groove, the groove angle is 19°, the welding groove gap 101 is 10mm, and the welding groove does not leave blunt side;

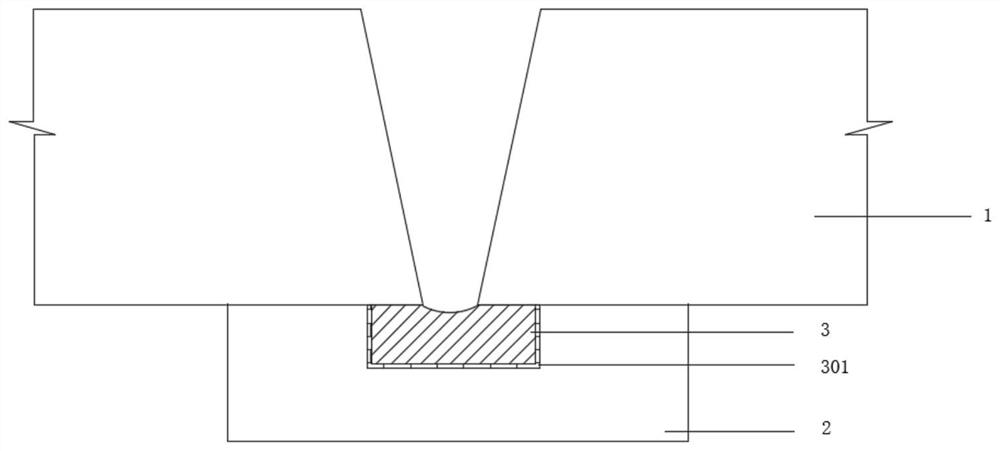

[0028] (2) Assemble the steel plate 2, the back of the weld is welded and fixed by the steel plate 2 and the steel plate 1, and the distance between the steel plate 2 is 400mm;

[0029] (3) Install the liner 3 on the back of the welding groove. When installing the liner 3, you need to use a wooden wedge...

specific Embodiment 2

[0034] Such as Figure 1 to Figure 3 As shown, a gas-electric vertical welding method for high-strength steel plates for a 50mm hull includes the following specific steps:

[0035] (1) Set the groove with the test plate, the test plate is made of high-strength steel EH36 for the hull, the thickness is 50mm, the required value of the tensile strength is 490-630 (MPa), the impact energy AKV ≥ 34J at the welded joint at 0 ° C, the specification of the test piece It is 1500mm (length) × 400mm (width) × 50mm (thickness), the welding groove type adopts single-sided V-shaped groove, the groove angle is 18°, the welding groove gap 101 is 9mm, and the welding groove does not leave blunt edges ;

[0036] (2) Assemble the steel plate 2, the back of the weld is welded and fixed by the steel plate 2 and the steel plate 1, and the distance between the steel plate 2 is 400mm;

[0037] (3) Install the liner 3 on the back of the welding groove. When installing the liner 3, you need to use a ...

specific Embodiment 3

[0042] Such as Figure 1 to Figure 3 As shown, a gas-electric vertical welding method for high-strength steel plates for a 42mm hull includes the following specific steps:

[0043] (1) Set the groove with the test plate. The test plate is made of high-strength steel EH36 for the hull, the thickness is 42mm, the required value of the tensile strength is 490-630 (MPa), the impact energy AKV≥34J at the welded joint -20℃, the test piece The specification is 1500mm (length) × 400mm (width) × 50mm (thickness), the welding groove type adopts single-sided V-shaped groove, the groove angle is 21°, the welding groove gap 101 is 8mm, and the welding groove does not leave blunt side;

[0044] (2) Assemble the steel plate 2, the back of the weld is welded and fixed by the steel plate 2 and the steel plate 1, and the distance between the steel plate 2 is 400mm;

[0045] (3) Install the liner 3 on the back of the welding groove. When installing the liner 3, you need to use a wooden wedge 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com