Large-breadth laser hole cutting method for glass

A large-format, laser cutting technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problem that laser cutting holes cannot meet the needs of large-format

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The method is described in detail through Embodiment 1 in conjunction with the accompanying drawings.

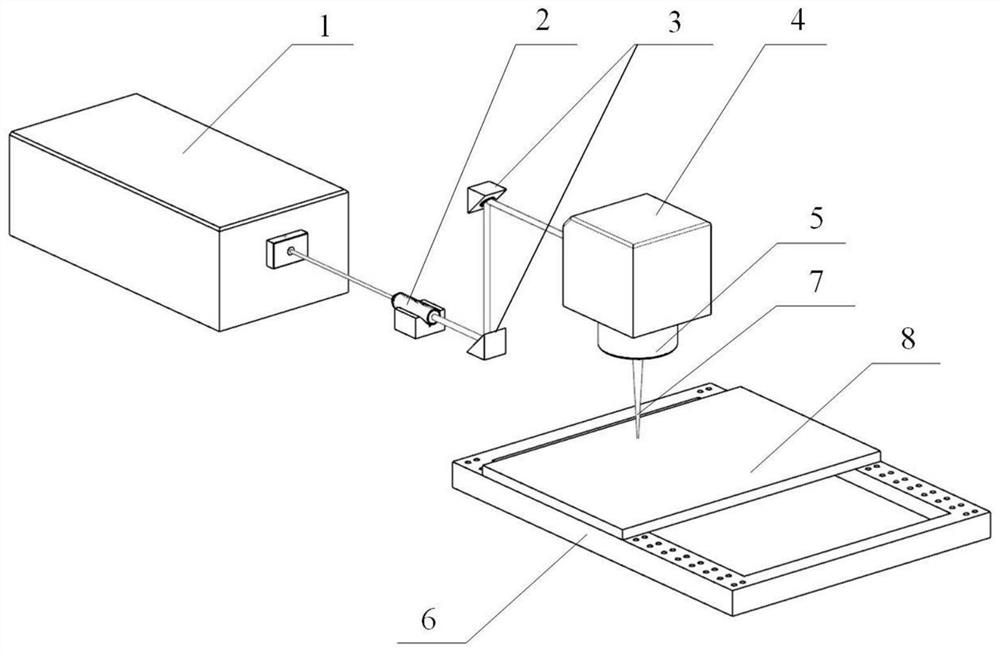

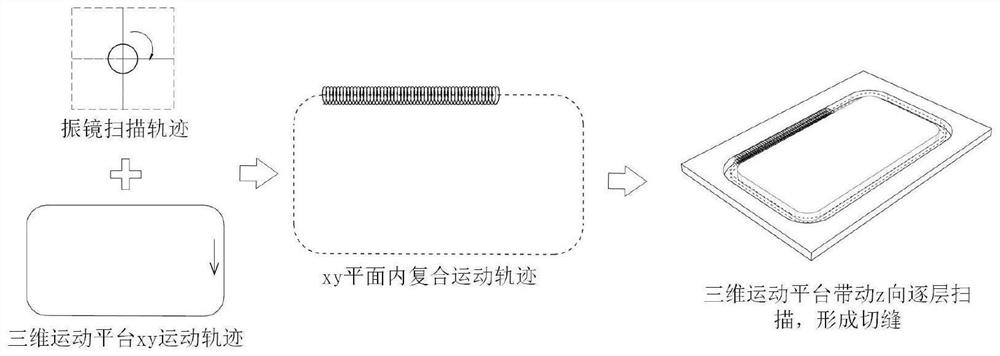

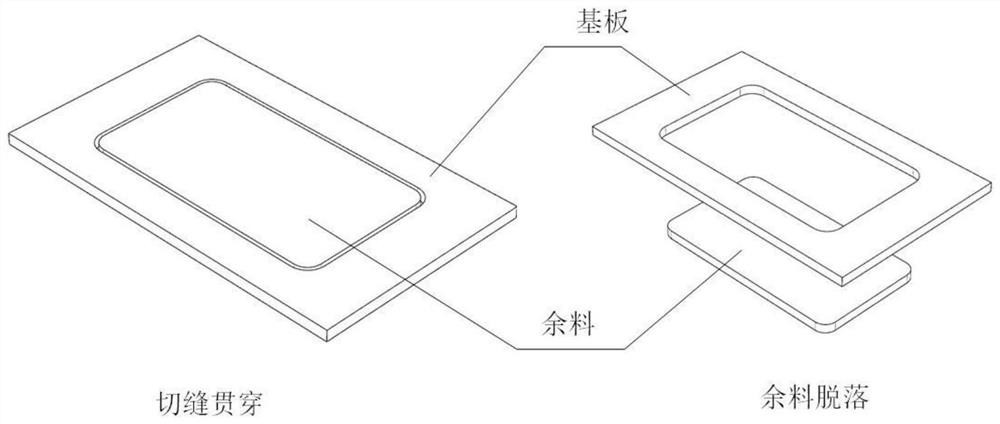

[0043] Such as figure 1 Shown is a three-dimensional schematic diagram of an embodiment of large-format laser cutting of glass according to the present invention. The main equipment of the glass large-format laser cutting process is composed of a laser 1, a beam expander 2, a reflector 3, a digital galvanometer 4, a focusing field mirror 5 and a three-dimensional motion platform 6. The laser beam 7 emitted by the laser 1 passes through the beam expander 2 The beam expander and mirror 3 are reflected and transmitted into the digital vibrating mirror 4, and the digital vibrating mirror 4 scans the laser beam 7 along the set track under software control, and the scanning laser beam output by the digital vibrating mirror 4 is focused by the focusing field mirror 5 Form a focused spot with a peak power density higher than the damage threshold of the glass workpiece 8. The...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap