Adjustable diameter multi-axis drill

A drill, adjustable technology, applied in the direction of boring/drilling, drilling/drilling equipment, boring machine/drilling machine parts, etc., can solve the problems of small cutting aperture, small adjustment range, small cutting force, etc. Achieve the effects of improving cutting force, expanding range, increasing the number of axes for cutting and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

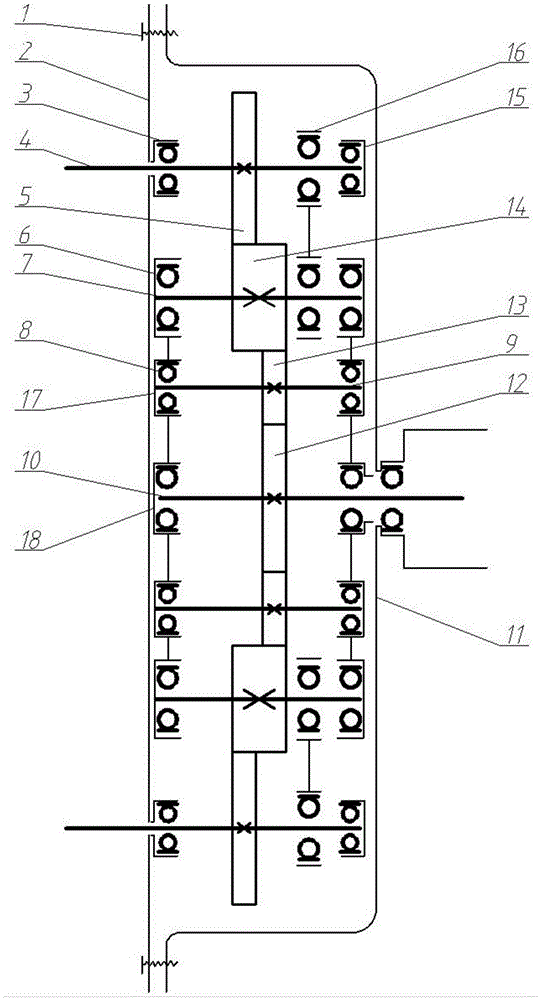

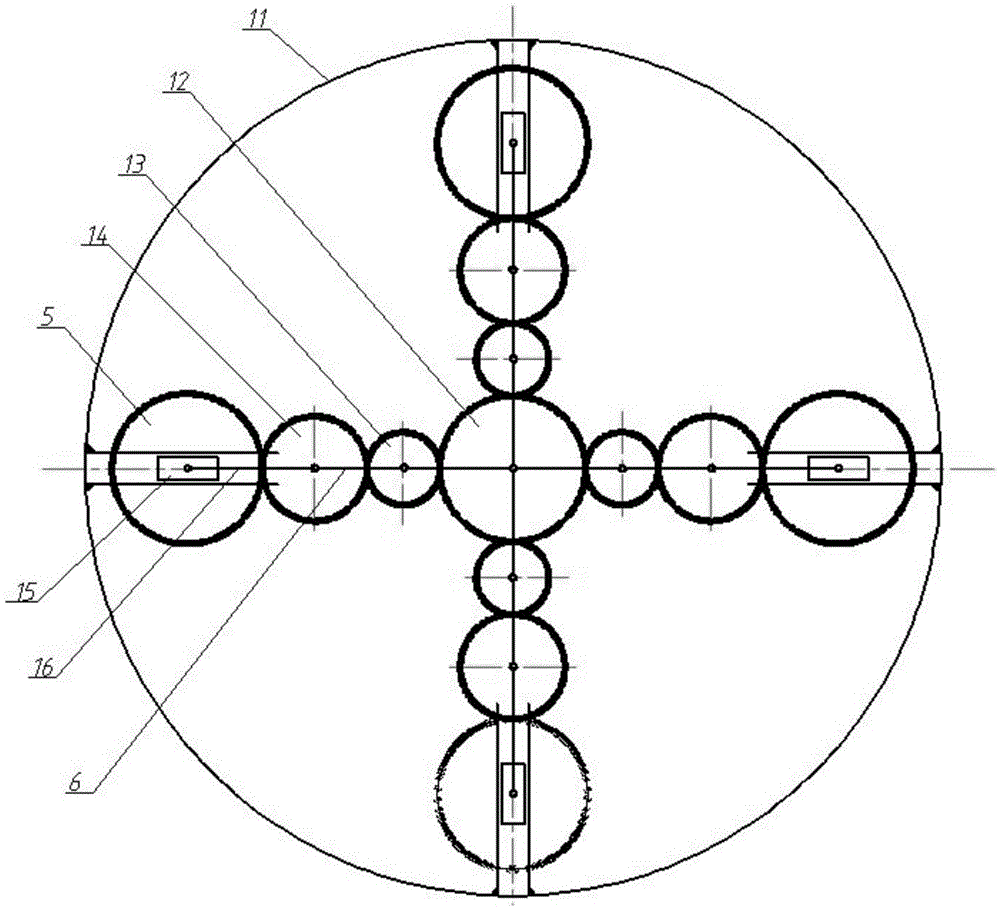

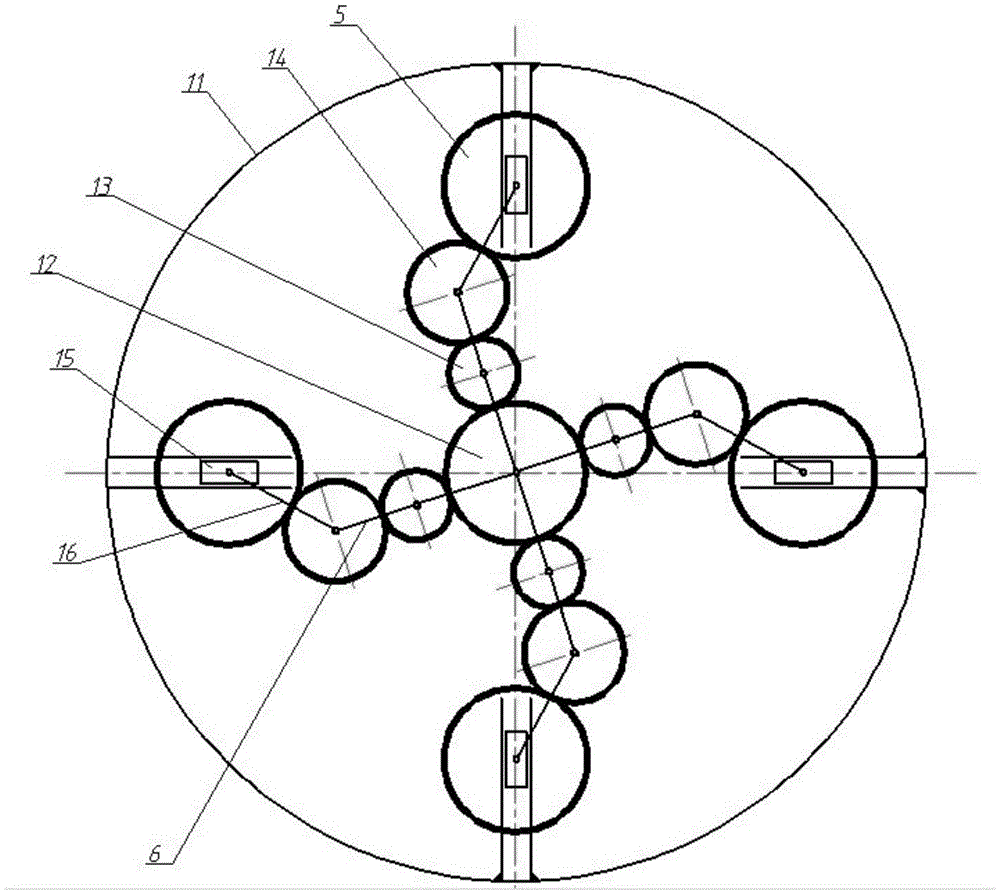

[0025] The radial distance adjustable multi-axis drill of the present invention has a structure such as figure 1 As shown, the drill housing is included, and the drill housing includes a cylindrical upper shell 11 and a circular lower cover 2, and a plurality of fastening screws 1 are passed between the cylindrical upper shell 11 and the circular lower cover 2. Threaded connection; the center in the drill housing is vertically provided with a one-axis 10, and four radial distance adjustment devices are symmetrically arranged in the drill housing according to the direction from the first axis 10 to the inner wall of the drill housing.

[0026] A plurality of holes are evenly arranged on the edge of the circular lower cover 2 , and a plurality of fastening screws 1 pass through the holes provided on the circular lower cover 2 and threadedly con...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap