Movable lifting stair special for stainless steel tank machining

A technology of stainless steel and stairs, which is applied in the direction of lifting devices, etc., can solve the problems that the height adjustment distance is in a limited state and cannot be adjusted in multiple levels, and achieve the effect of expanding the lifting range, facilitating assembly and disassembly, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be described in further detail below with reference to the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

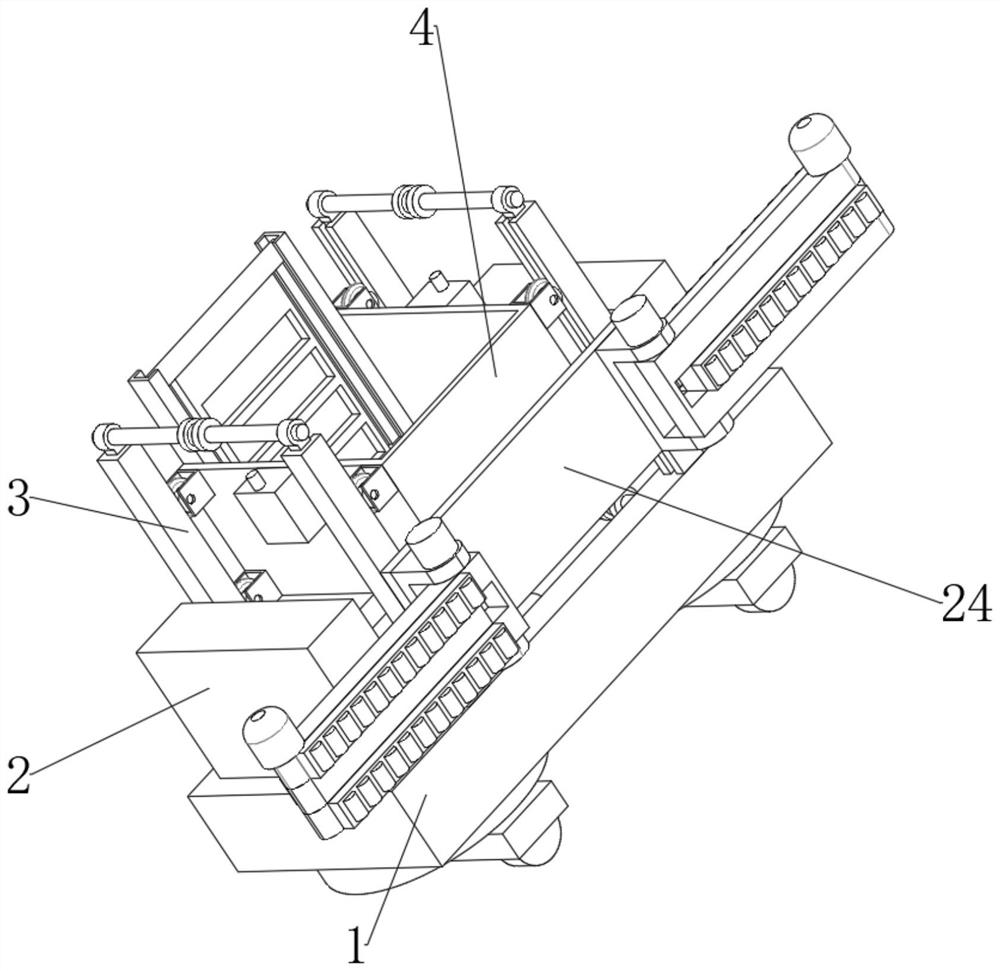

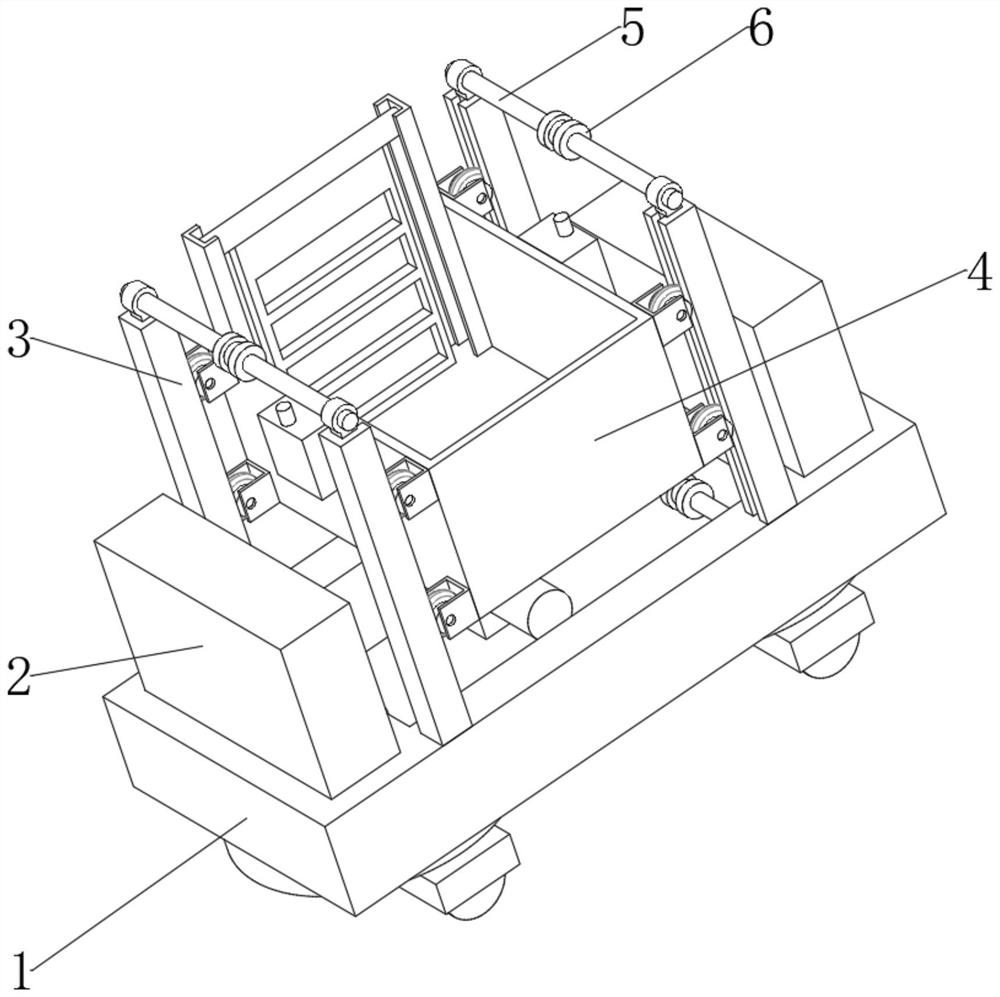

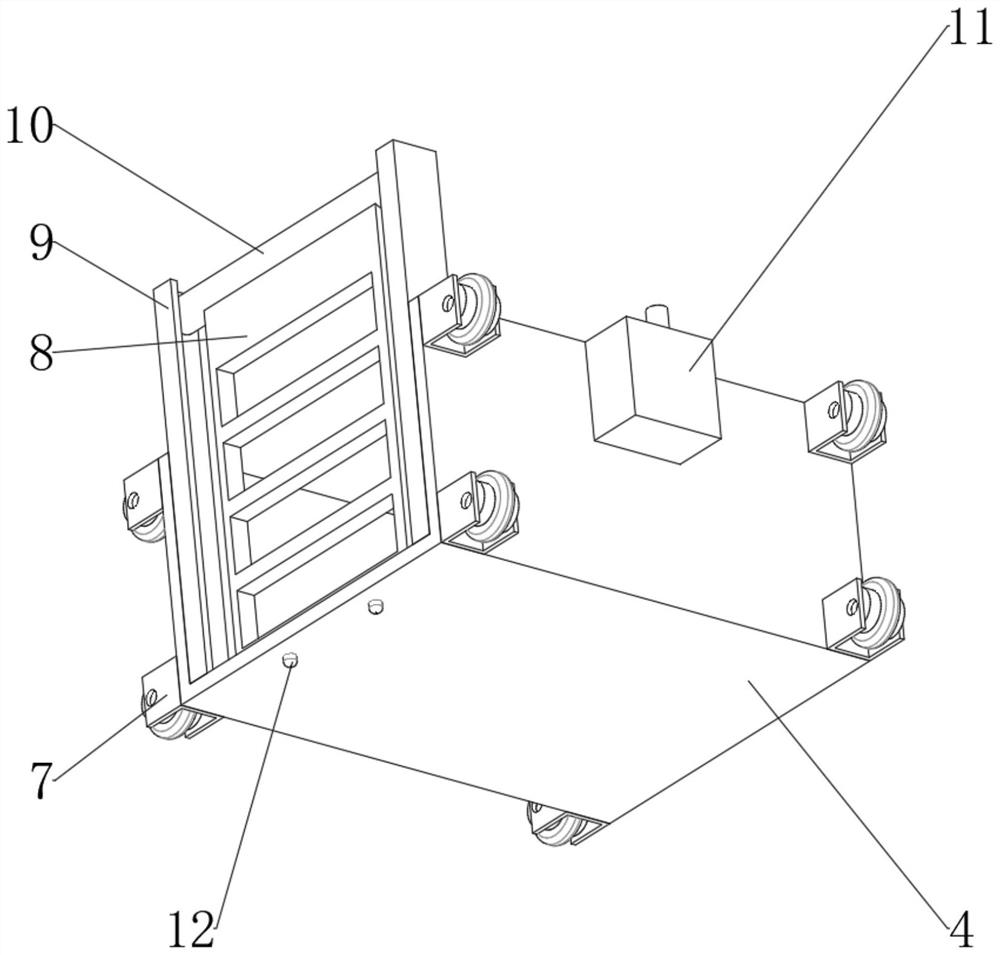

[0029] like Figure 1-Figure 9 As shown, the movable lift stairs specially provided for the processing of stainless steel tanks provided in this embodiment include a base plate 1 and a frame assembly arranged on the top thereof, a riding assembly is arranged inside the frame assembly, and the frame assembly includes four fixedly connected to the top of the base plate 1. The upright column 3 and the sliding sleeve 17 arranged on its inner wall, the top of the base plate 1 is provided with a telescopic cylinder 18, the piston rod of the telescopic cylinder 18 is fixedly connected with the sliding sleeve 17, the top of the sliding sleeve 17 is provided with a ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com