Photosensitive conductive structure and touch sensor

A conductive structure, photosensitive technology, applied in the direction of instrument, electrical digital data processing, data processing input/output process, etc., can solve problems such as unstable contact impedance, and achieve the effect of overcoming high contact impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

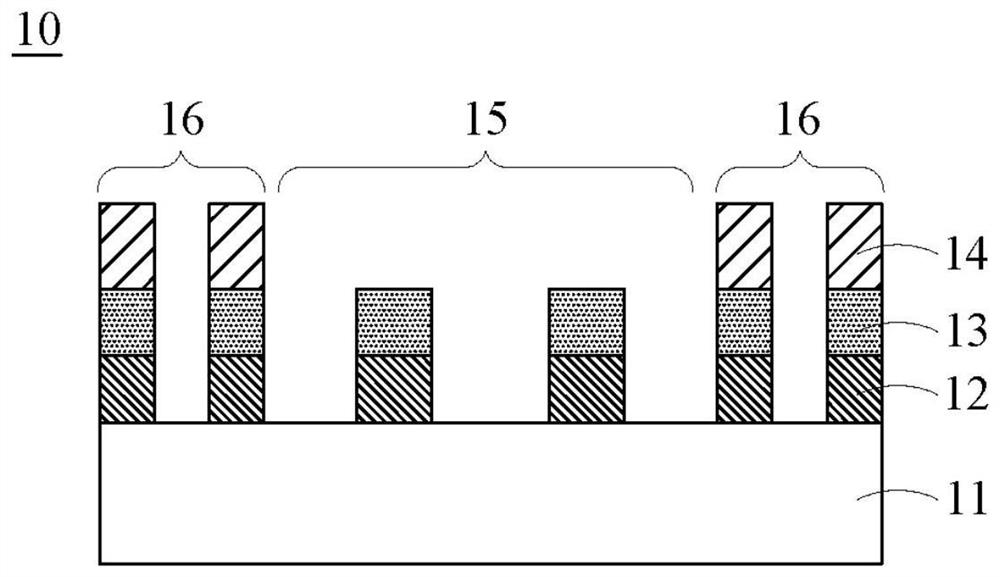

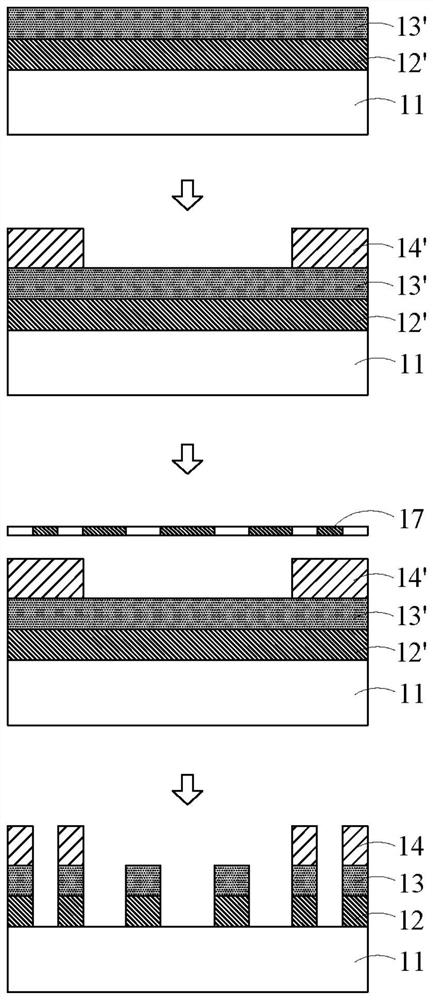

[0086] figure 1 It is a schematic diagram of the photosensitive conductive structure of Embodiment 1 of the present invention. Such as figure 1 As shown, the photosensitive conductive structure 10 of Embodiment 1 of the present invention includes: a substrate 11; a lift-off photosensitive resin layer 12, which is arranged on the substrate 11; a nano-silver layer 13, which is arranged on On the lift-off type photosensitive resin layer 12; and a photosensitive conductive layer 14, which is arranged on the edge of the nano-silver layer 13, so as to define that the nano-silver layer 13 is not covered by the photosensitive conductive structure 10 A visible area 15 covered by the photosensitive conductive layer 14 , and a peripheral circuit area 16 covered by the photosensitive conductive layer 14 of the nano-silver layer 13 . Wherein, the average molecular weight (Mn) of the lift-off photosensitive resin layer 12 is greater than 3,000 and less than 100,000. Wherein, the photosen...

Embodiment 2

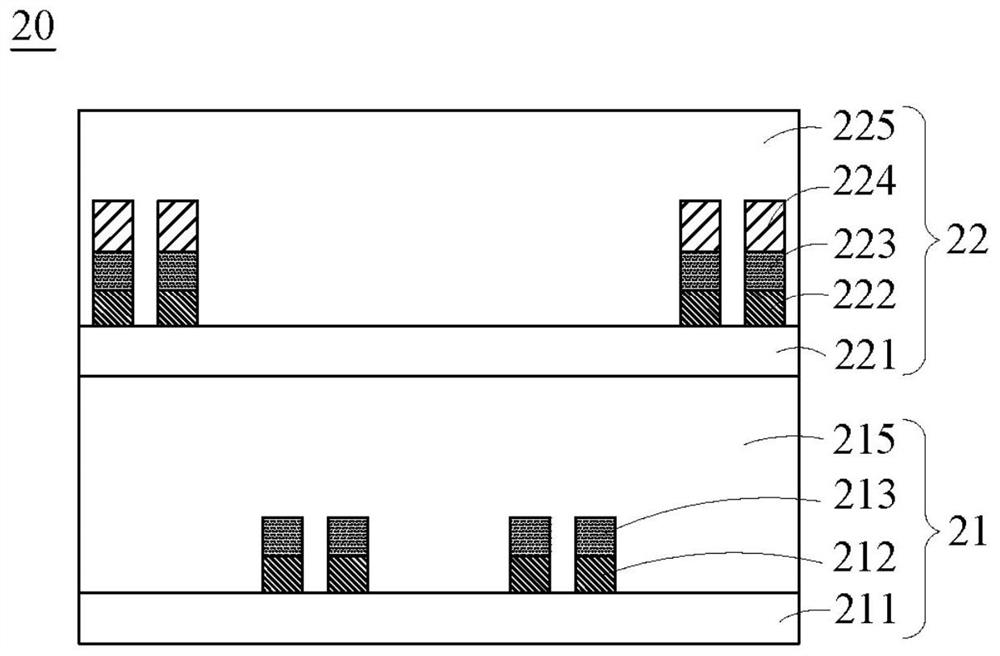

[0103] image 3 It is a schematic diagram of the touch sensor according to Embodiment 2 of the present invention. Such as image 3 As shown, the touch sensor 20 of this embodiment includes: a first photosensitive conductive structure 21 ; and a second photosensitive conductive structure 22 disposed on the first photosensitive conductive structure 21 . Wherein, the first photosensitive conductive structure 21 includes: a first substrate 211; a first lift-off photosensitive resin layer 212, which is arranged on the first substrate 211; a first nano-silver layer 213, which disposed on the first lift-off photosensitive resin layer 212 ; and a first optical adhesive 215 (Optically Clear Adhesive, OCA), disposed on the first nano-silver layer 213 . Wherein, the second photosensitive conductive structure 22 includes: a second substrate 221; a second lift-off photosensitive resin layer 222, which is arranged on the second substrate 221; a second nano silver layer 223, which Set on ...

Embodiment 3

[0108] Figure 4 It is a schematic diagram of a touch sensor according to Embodiment 3 of the present invention. Such as Figure 4 As shown, the photosensitive conductive structure 30 of this embodiment includes: a substrate 31; a first lift-off photosensitive resin layer 312, which is arranged on the substrate 31; a first nano-silver layer 313, which is arranged On the first lift-off photosensitive resin layer 312; a first photosensitive conductive layer 314, which is arranged on the edge of the first nano-silver layer 313, to define the first photosensitive conductive structure 30 A visible region 315 where a silver nanometer layer 313 is not covered by the first photosensitive conductive layer 314, and a peripheral circuit region 316 where the first nanosilver layer 313 is covered by the first photosensitive conductive layer 314; Two lift-off photosensitive resin layers 322, which are arranged under the substrate 31; a second nano-silver layer 323, which is arranged under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com