Shear flattening and cleaning device for cans

A technology for cleaning devices and cans, which is applied to the removal of solid waste, etc. It can solve the problems of machine jamming, feeding roller slippage, and difficulty in popularization, and achieve the effects of low machine failure rate, high conveying accuracy, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

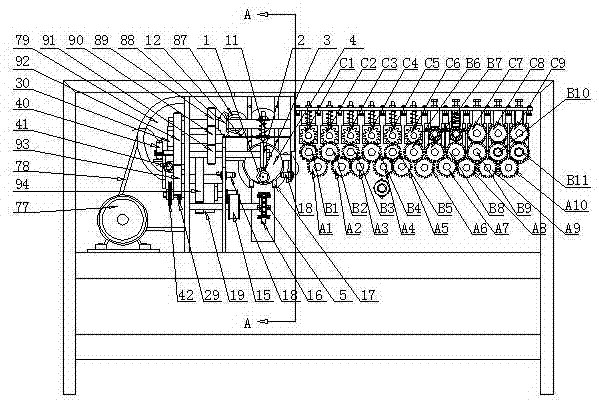

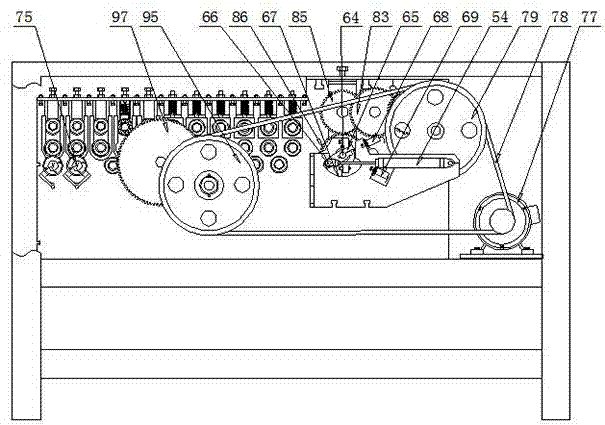

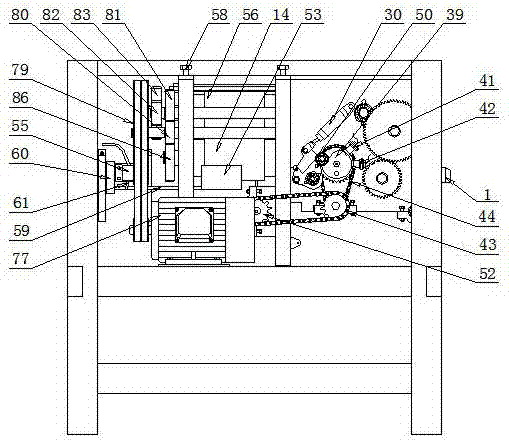

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 and Figure 11 As shown, this embodiment includes a frame, a shearing and conveying device, a feeding mechanism and a flattening device, a washing, squeezing and drying device, a transmission device and a control system.

[0027] The shearing and conveying device includes a feed shaft 1 fixed on the front end of the frame to match the tank body, an upper knife 2, a lower knife 3 fixed on the upper end of the feed shaft, a conical expansion shaft 4, a conveying chain 5, and a driving chain The operation control device of wheel 6, passive sprocket 7 and driving sprocket. The upper knife 2 is inlaid on the upper knife rest 8, and the upper knife rest 8 is fixed on the upper knife shaft 9, and the upper knif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com