State recognition method based on time-varying data and multi-scale microscopic vibration data analysis

A technology of time-varying data and vibration data, applied in character and pattern recognition, instruments, calculations, etc., can solve the problems of reciprocating mechanical fault identification and diagnosis, and achieve the goal of avoiding excessive dependence, accurate identification, and improving state identification accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0155] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0156] The state identification method based on time-varying data analysis includes the following steps:

[0157] Step 1. Measurement of working process data

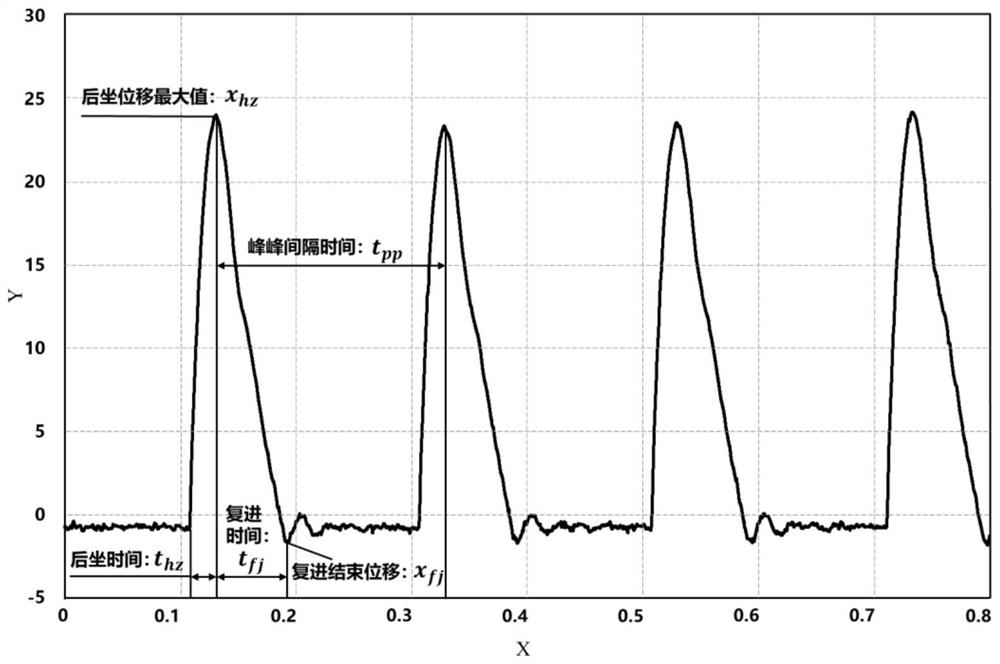

[0158] According to the working mechanism and failure mode analysis of the anti-recoil device, the working process data is collected through multiple sensors. The anti-recoil device is composed of a retreating machine and a re-entrying machine. The common failure modes in the reciprocating motion are too long recoil, too short recoil, insufficient re-entry, and excessive re-entry. Move data, velocity data, and acceleration data back and forth.

[0159] Step 2. Anti-recoil device fault feature recognition method based on time-varying data

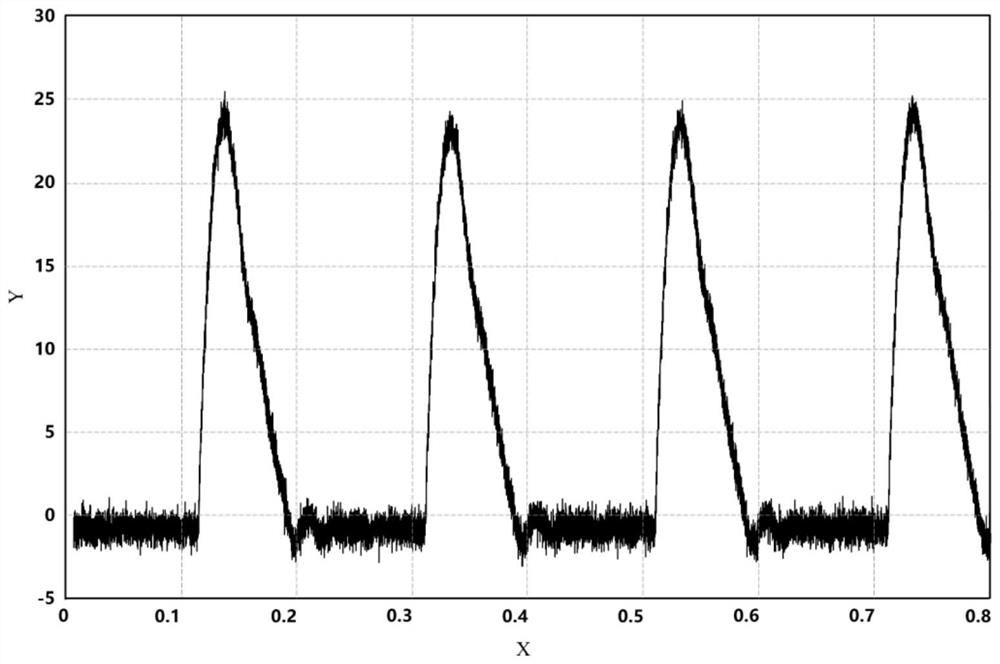

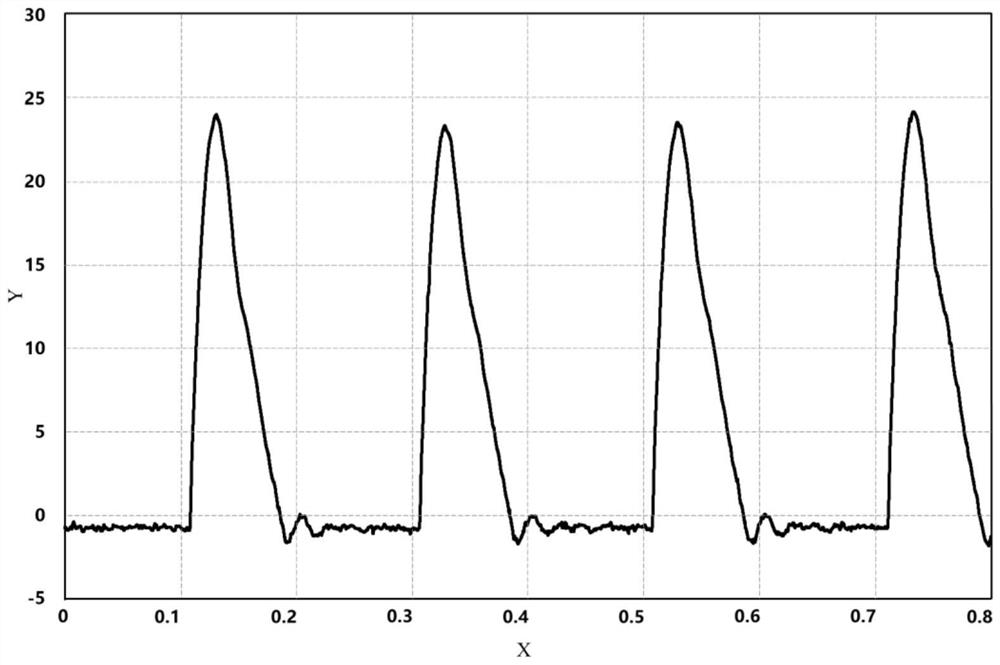

[0160] 2-1 Abnormal data removal

[0161] Remove abnormal data: Abnormal data refers to monitoring values that do not conform to the trend of the entire time s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com