Driven compression roller assembly and AOI detection device applying same

A pressure roller component and detection device technology, which is applied in the direction of optical testing for flaws/defects, sorting, etc., can solve problems such as easy out of focus of the camera, affecting the quality and efficiency of inspection, up and down of the material belt, and left and right deviation, etc., to reduce The effect of misjudgment stoppage and unqualified product rejection stoppage, improvement of inspection quality and work efficiency, and improvement of feeding stability and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

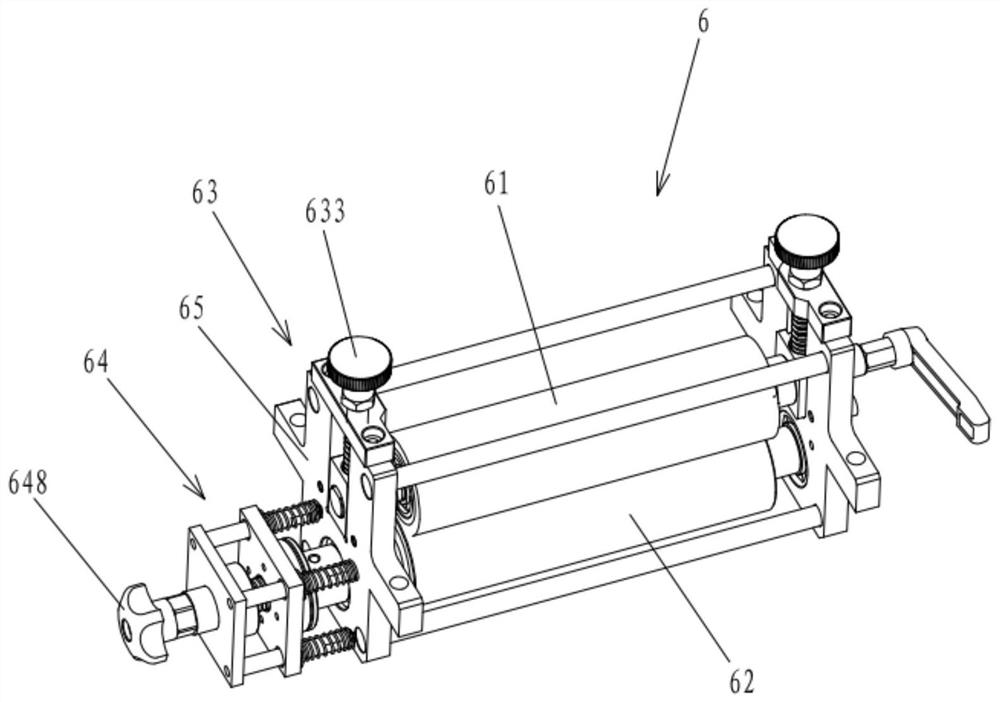

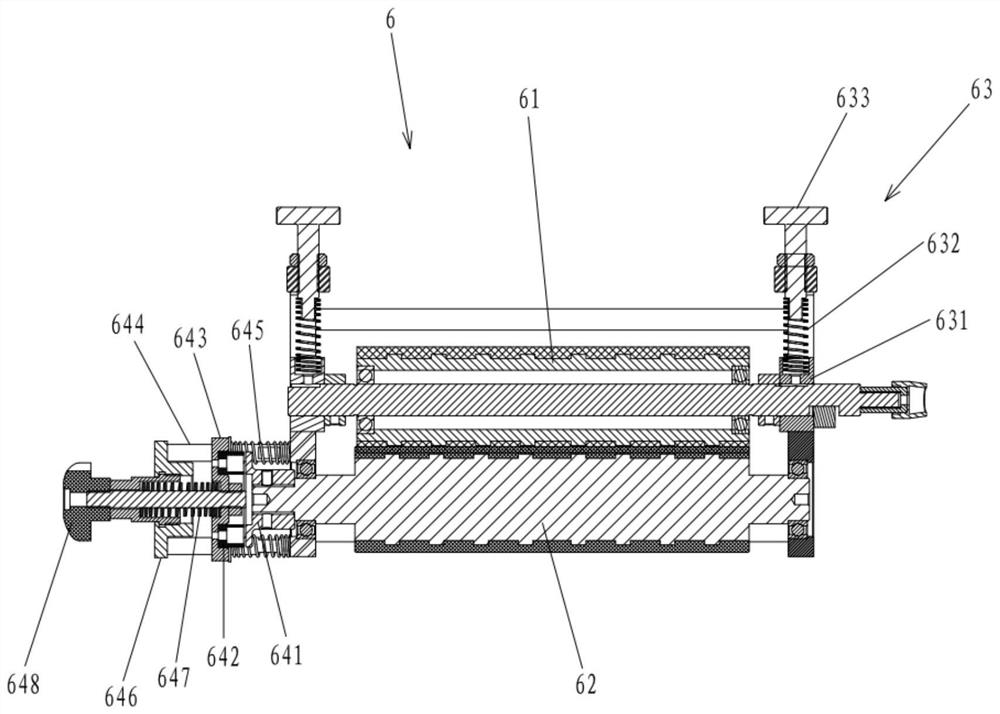

[0032] refer to Figure 1 to Figure 3 , a driven pressure roller assembly, including a first roller body 61, a second roller body 62 and a bracket 65, the first roller body 61 and the second roller body 62 are rotatably connected to the bracket 65;

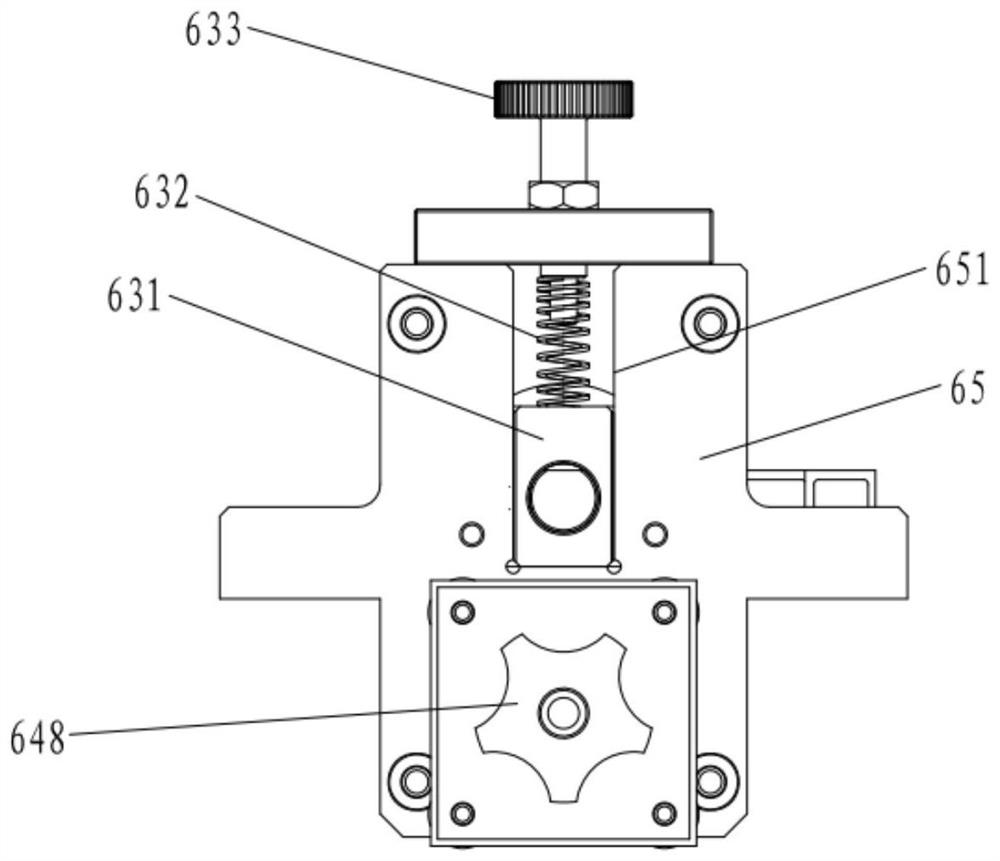

[0033] It also includes a compression adjustment structure 63 and a damping adjustment structure 64, the compression adjustment structure 63 can adjust the compression force between the first roller body 61 and the second roller body 62;

[0034] The damping adjustment structure 64 can adjust the torque of the second roller body 62 .

[0035] The driven pressure roller assembly 6 is used to compress the material belt, so that the material belt is not easy to shift left and right when it moves, and also makes the material belt maintain a certain tension when it moves, preventing the material belt from loosening a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com