Reverse steel guardrail and construction method thereof

A guardrail and reverse technology, applied in the direction of fences, building types, buildings, etc., can solve the problems of reducing work efficiency and achieve the effect of convenient installation, simple and efficient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following is attached Figure 1-5 The application is described in further detail.

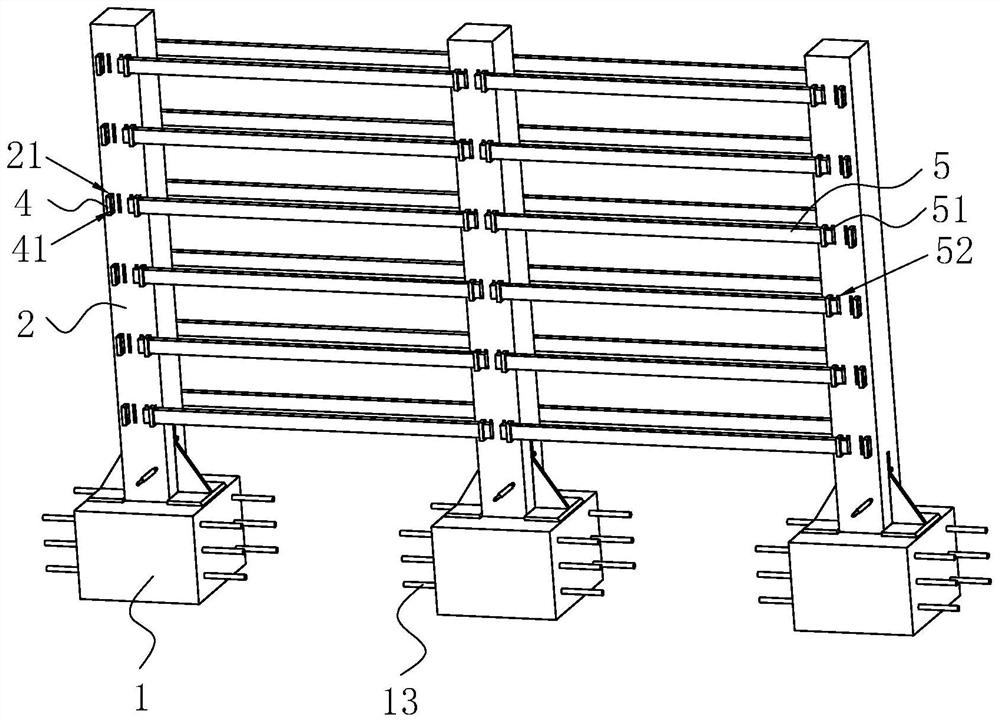

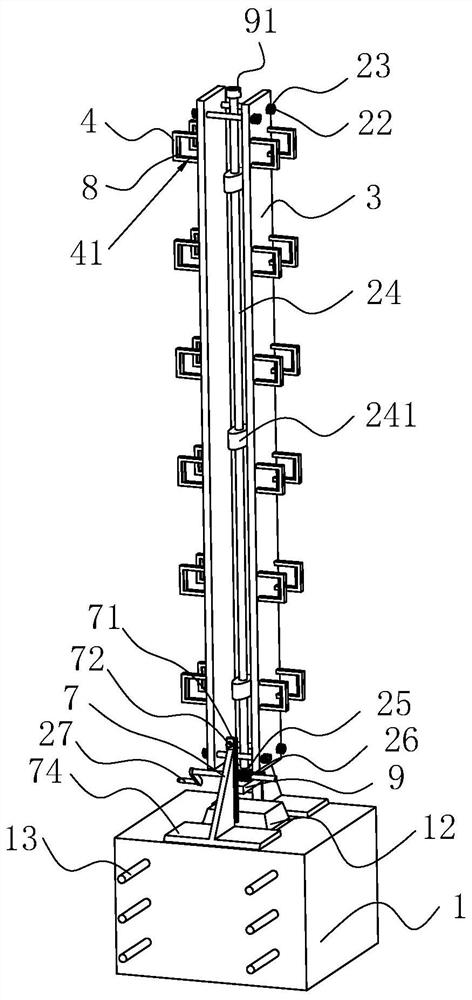

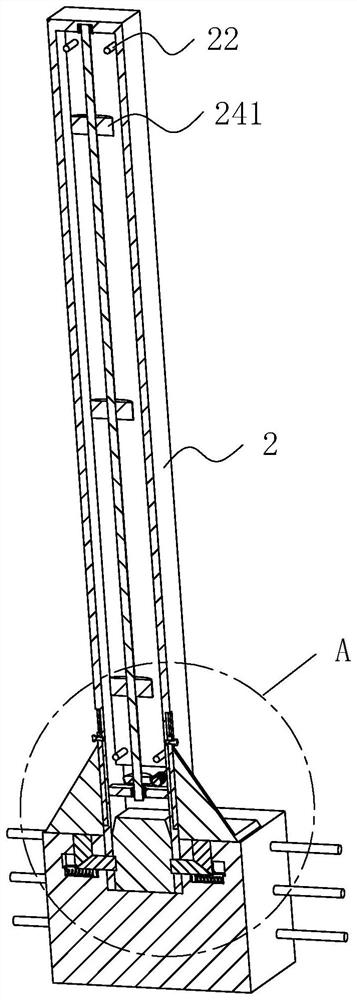

[0040] The embodiment of the present application discloses an upside-down steel guardrail. refer to figure 1 and figure 2 As shown, a reverse steel guardrail includes a plurality of prefabricated blocks 1 for pouring on the ground, and a plurality of steel bars 13 are poured on the prefabricated block 1, and the steel bars 13 can increase the strength of the prefabricated block 1 and the ground, And each prefabricated block 1 is all provided with column 2, and column 2 is hollow setting, in column 2 and is positioned at the both sides of column 2 sliding and is provided with fixed plate 3, the sliding direction of fixed plate 3 and the length direction of column 2 mutually Vertically, the two fixed plates 3 are fixedly provided with positioning plates 4 on the faces far away from each other. The through hole 21 passed by the positioning plate 4 is provided with a plurality of cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com