Fixed clamping structure of element box

A technology for fixing cards and component boxes, which is applied to electrical components, chassis/cabinet/drawer parts, electrical equipment shells/cabinets/drawers, etc. Inconvenient disassembly and other problems, to achieve the effect of material saving, convenient operation and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Objects, advantages and features of the present invention will be illustrated and explained by the following non-limiting description of preferred embodiments. These embodiments are only typical examples of applying the technical solutions of the present invention, and all technical solutions formed by adopting equivalent replacements or equivalent transformations fall within the protection scope of the present invention.

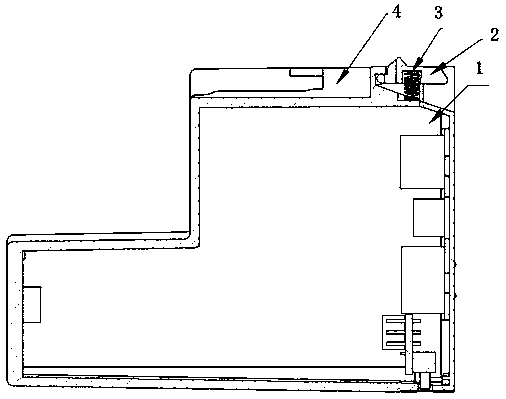

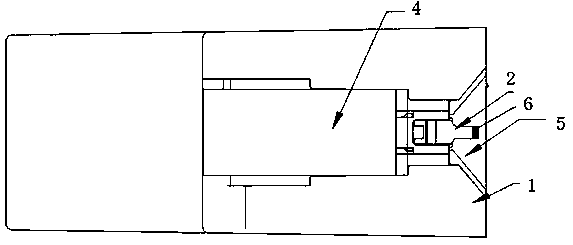

[0015] The invention discloses a fixed clamping structure of a component box, such as figure 1 and figure 2 As shown, the fixed clamping structure is arranged on the component box housing 1, and the fixed clamping structure includes a tongue 2, an elastic member 3, a guide slot 4 and a guide groove 5, the guide slot, the tongue, the guide The grooves are all arranged on the same plane on one side of the component box housing. In this technical solution, the guide slots are preferably C-shaped guide slots, and the guide slots are preferably V-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com