MARK3 liquid dome material hole plug manufacturing auxiliary device, manufacturing method and plug

A technology of auxiliary devices and material holes, applied in the direction of material gluing, connecting components, household components, etc., can solve the problems of high precision requirements, achieve the effect of firm installation and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention is further described below in conjunction with specific embodiments:

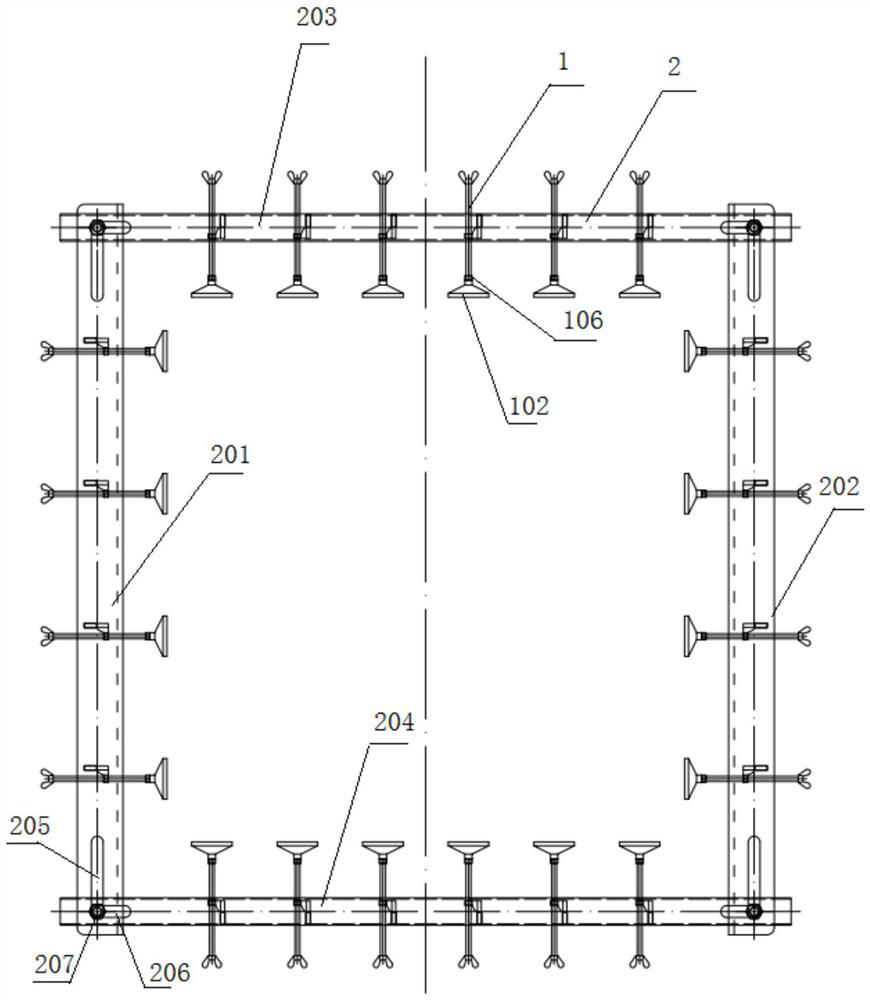

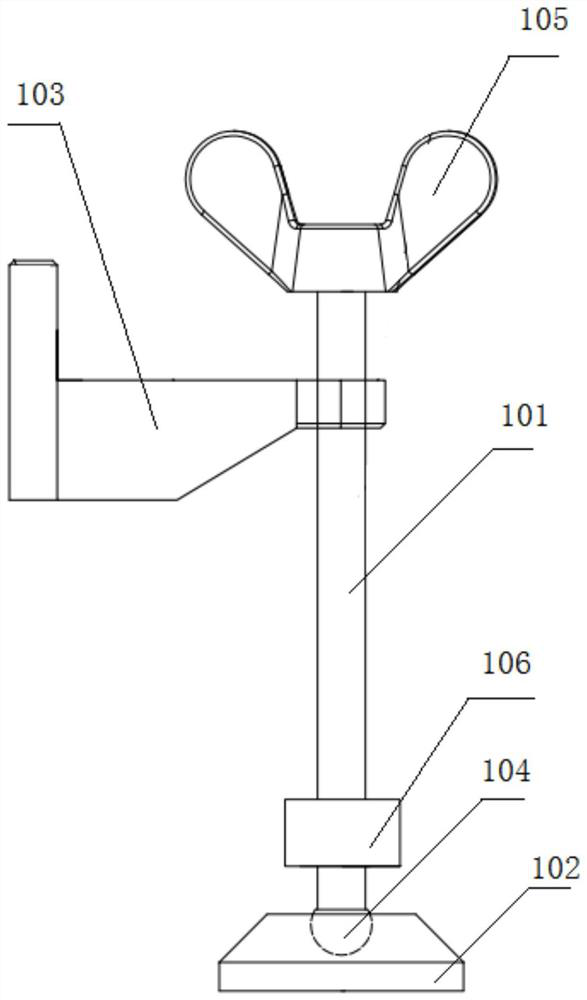

[0027] An auxiliary device for making a MARK3 liquid dome material hole plug, such as figure 1 As shown, its structure includes a rectangular frame body 2, several spider legs 1 symmetrically distributed along the four sides of the rectangular frame body, the spider leg 1 includes an adjustment screw 101, a leg 102, the leg 102 is installed on one end of the adjustment screw 101, and the adjustment screw 101 is vertical On one side of the rectangular frame where it is located, the adjusting screw 101 is parallel to the surface formed by the four sides of the rectangular frame; the legs 102 are located in the rectangular frame; the adjusting screw 101 is threadedly installed with the rectangular frame.

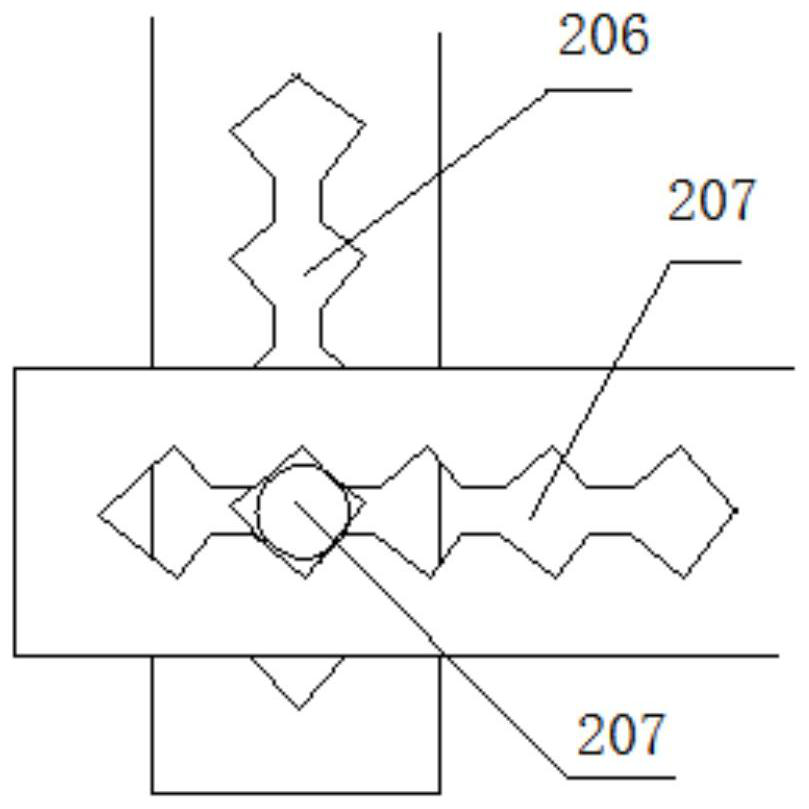

[0028] In this embodiment, the mounting block 103 is welded on the rectangular frame, and the mounting block 103 is provided with an internally threaded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com