Composite bulletproof flashboard adopting multiple layers of UD and manufacturing device

A technology for making bulletproof boards and devices, which can be used in laminated devices, protective equipment, armor, etc., and can solve problems such as clumsy actions of users, lack of waterproofing, and affecting the use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Body armor, also known as bulletproof vest, bulletproof vest, bulletproof vest, bulletproof clothing, etc., is an individual soldier's body armor, which is used to protect the human body from bullets or shrapnel. Body armor in the past was very heavy, causing the user to move awkwardly in action. Modern bulletproof technology has made great progress, especially after the mass production of bulletproof inserts with light weight and high protection level, it has become more and more common in single standard equipment.

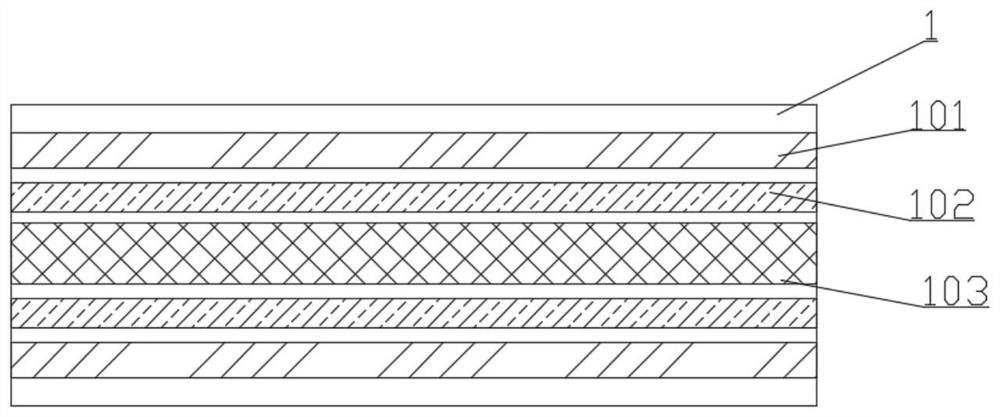

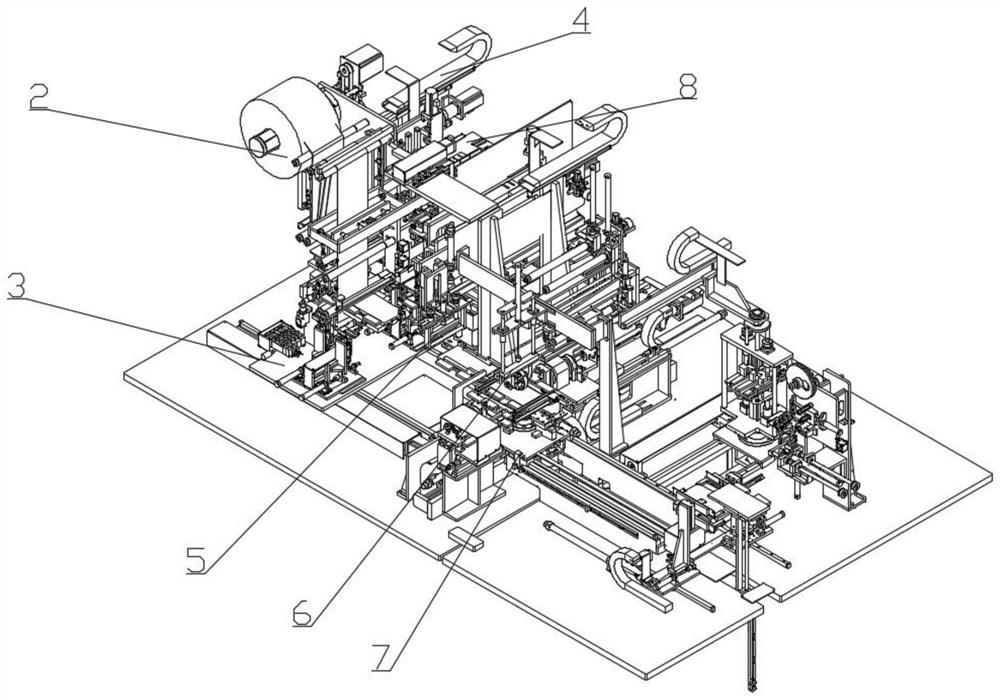

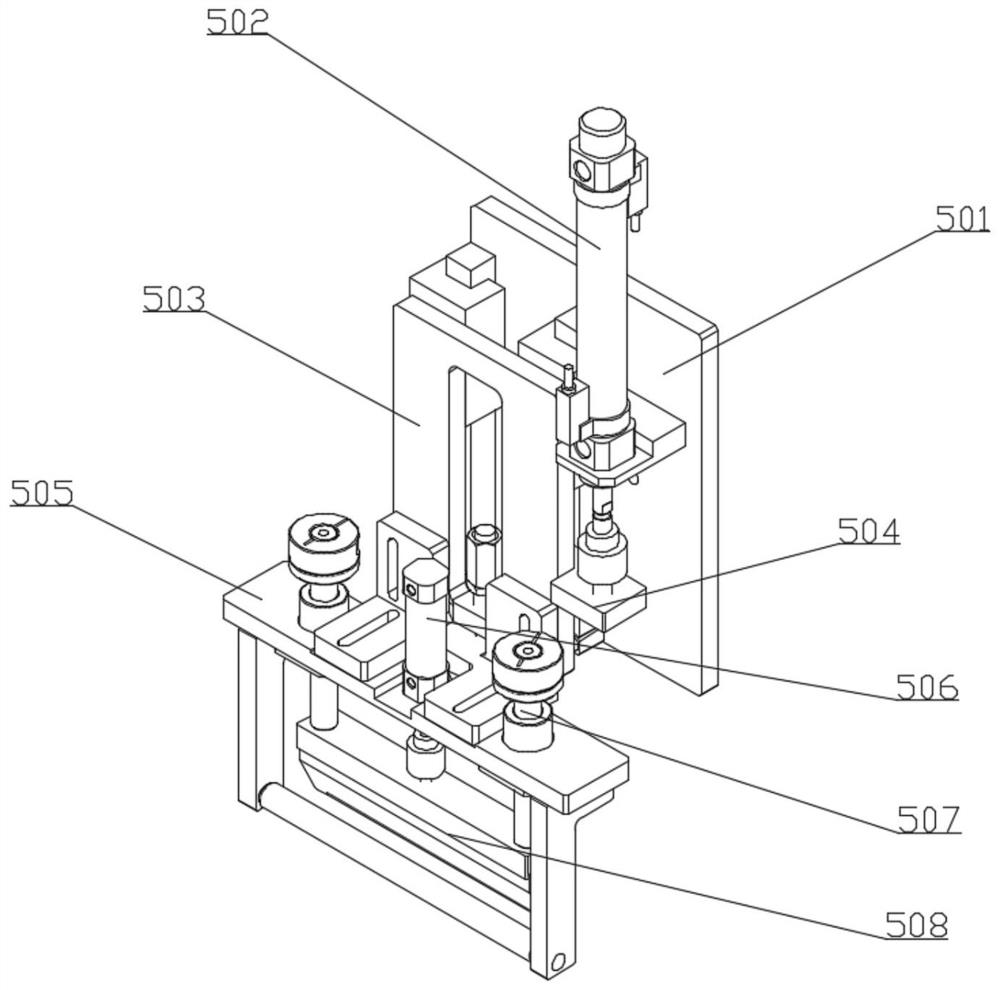

[0044] Such as Figure 1-8 As shown, the present invention provides a composite bulletproof board using multi-layer UD. The bulletproof board is marked as 1 and includes a waterproof layer 101, a buffer layer 102 and a bulletproof layer 103. The buffer layer 102 is placed symmetrically on both sides of the bulletproof layer 103. On the side, the waterproof layer 101 is symmetrically placed on both sides of the buffer layer 102, the waterproof layer 101 i...

Embodiment 2

[0054] Body armor, also known as bulletproof vest, bulletproof vest, bulletproof vest, bulletproof clothing, etc., is an individual soldier's body armor, which is used to protect the human body from bullets or shrapnel. Body armor in the past was very heavy, causing the user to move awkwardly in action. Modern bulletproof technology has made great progress, especially after the mass production of bulletproof inserts with light weight and high protection level, it has become more and more common in single standard equipment.

[0055] Such as Figure 1-8 As shown, the present invention provides a composite bulletproof board using multi-layer UD. The bulletproof board is marked as 1 and includes a waterproof layer 101, a buffer layer 102 and a bulletproof layer 103. The buffer layer 102 is placed symmetrically on both sides of the bulletproof layer 103. On the side, the waterproof layer 101 is symmetrically placed on both sides of the buffer layer 102, the waterproof layer 101 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com