Method for operating ultrasonic flowmeter and ultrasonic flowmeter

An ultrasonic flow and measuring instrument technology, which is applied in the measurement of flow/mass flow, fluid velocity measurement, liquid/fluid solid measurement, etc., can solve the problems of measurement accuracy influence, flow measurement repetition rate limitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

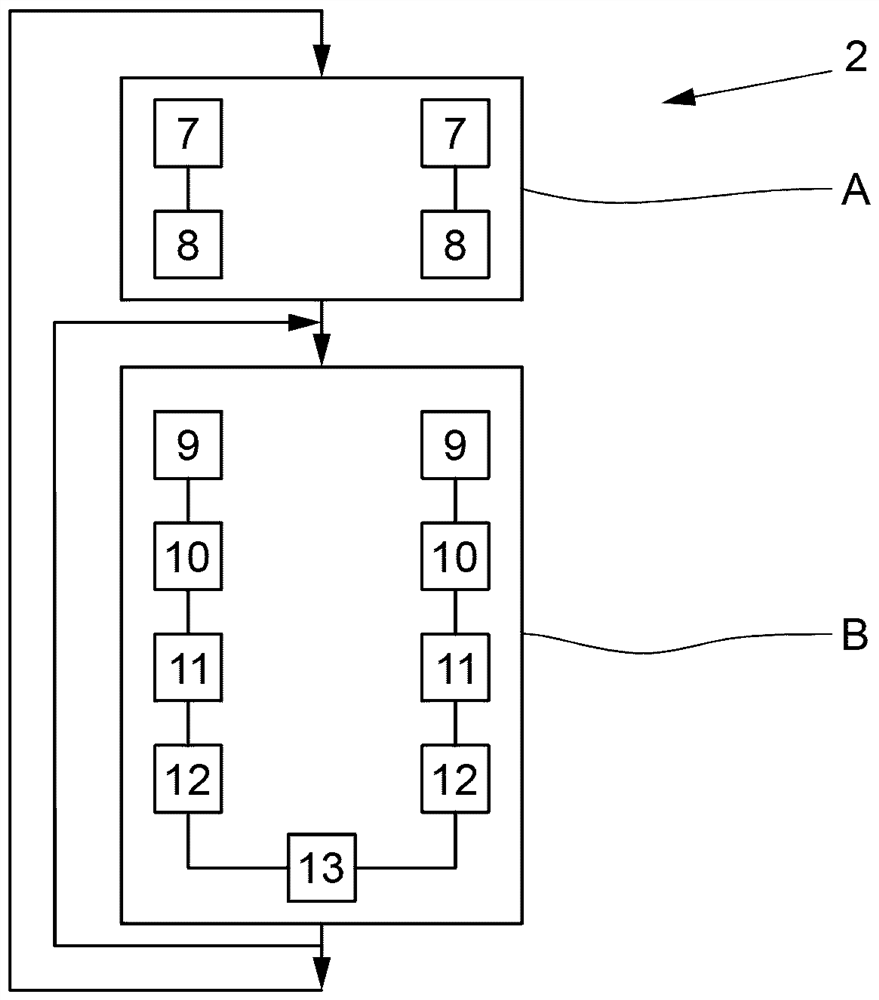

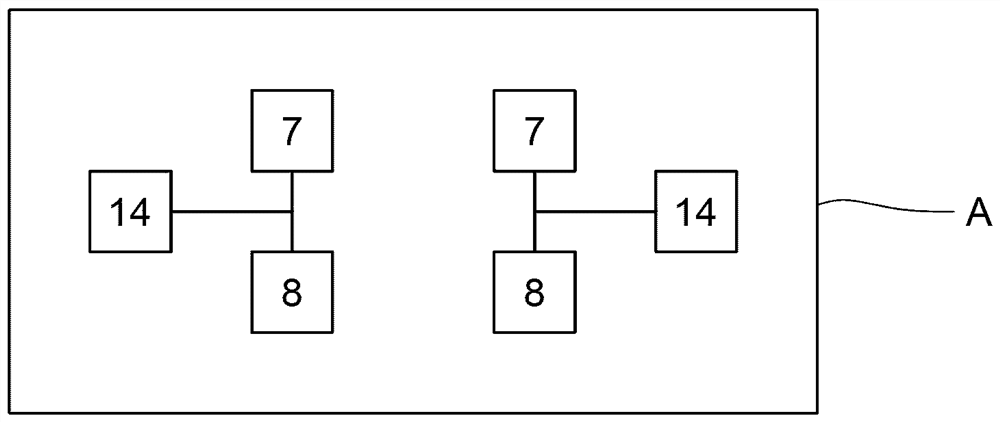

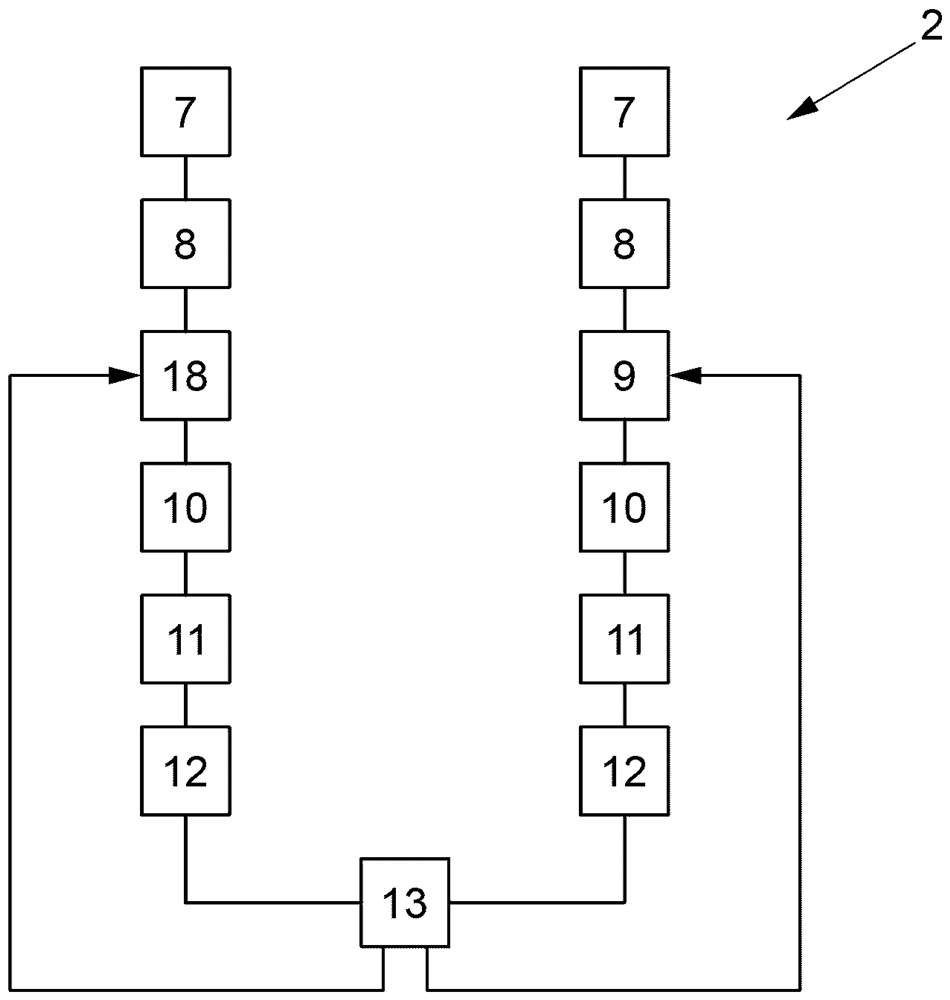

[0084] figure 1 An exemplary embodiment of an ultrasonic flowmeter 1 is shown, wherein the ultrasonic flowmeter 1 has an ultrasonic transducer pair consisting of a first ultrasonic transducer 3 and a second ultrasonic transducer 4 . Ultrasonic transducers 3 and 4 are arranged offset to one another in the flow direction on measuring tube 5 . In the illustrated embodiment, the direction of flow is indicated by arrows.

[0085] The two ultrasonic transducers 3 and 4 are designed not only as a transmitting unit but also as a receiving unit. In operation, the second ultrasonic transducer 4 receives the first measurement signal emitted by the first ultrasonic transducer 3 and the first ultrasonic transducer 3 receives the second measurement signal emitted by the second ultrasonic transducer 4 . Thus, the result is that during operation a measurement signal passes in the direction of flow (verlaufen) and a measurement signal passes opposite to the direction of flow. From the trans...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap