Automatic reinforcement distribution algorithm for three kinds of load-bearing steel bars on single side of underground diaphragm wall

A technology for underground diaphragm walls and stressed steel bars, applied in calculation, sheet pile walls, marketing, etc., can solve the problems of uncertainty in layout results and lack of uniform standards, and achieve the effect of improving design efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

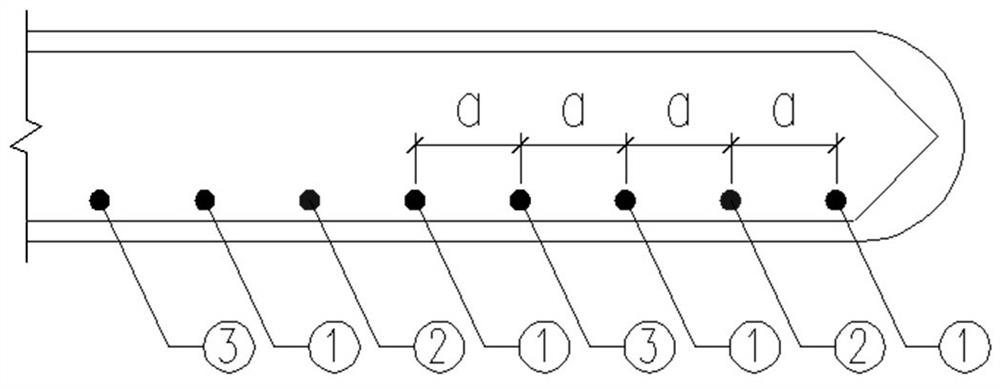

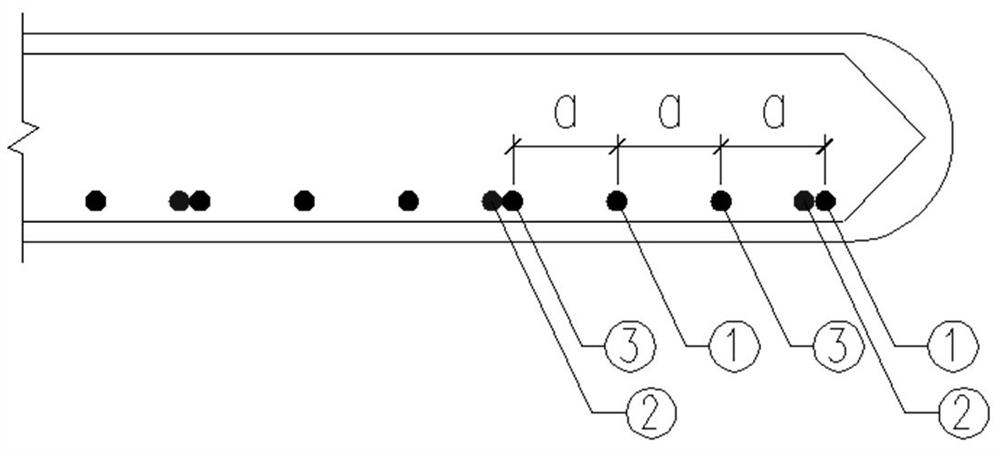

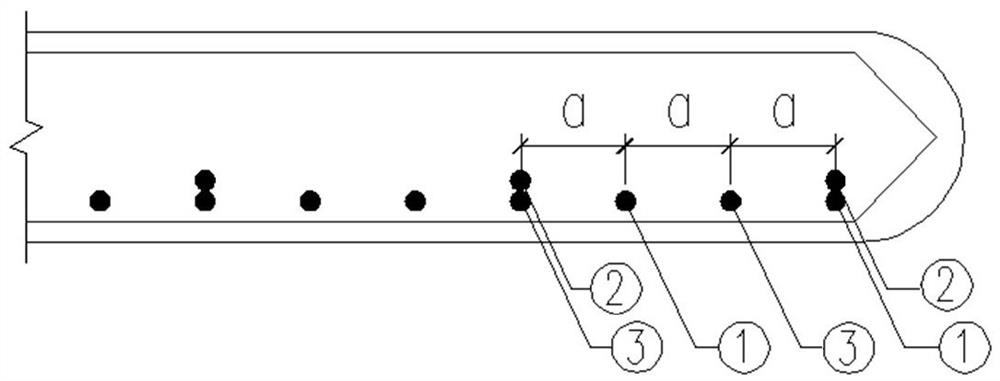

[0148] Example: such as Figure 1-24 As shown, this embodiment relates to an automatic reinforcement algorithm for three kinds of stressed steel bars on one side of an underground diaphragm wall. The algorithm includes the following steps:

[0149] (1) Preset eleven types of stress reinforcement arrangement schemes for three kinds of reinforcement (No. 1 reinforcement, No. 2 reinforcement and No. 3 reinforcement) in the underground diaphragm wall;

[0150] (2) The diameter D of the preset No. 1 steel bar 1 Same as the thickness h of the underground diaphragm wall and the spacing a of No. 1 steel bar 1 The associated default value table;

[0151] (3) Preset the cut-off sequence table of the steel bar type for the first time, the type of steel bar for the second time cut-off and the type of the layout scheme of the stressed steel bar;

[0152] (4) According to the default value table in step (2), input the thickness h of the underground diaphragm wall and the spacing a of No. 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com