Automobile wire harness connector

A technology for automotive wiring harnesses and connectors, applied to vehicle components, circuits or fluid pipelines, transportation and packaging, etc., can solve problems such as foreign matter entry, needle withdrawal, crooked needles, etc., to prevent foreign matter entry and improve connection stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

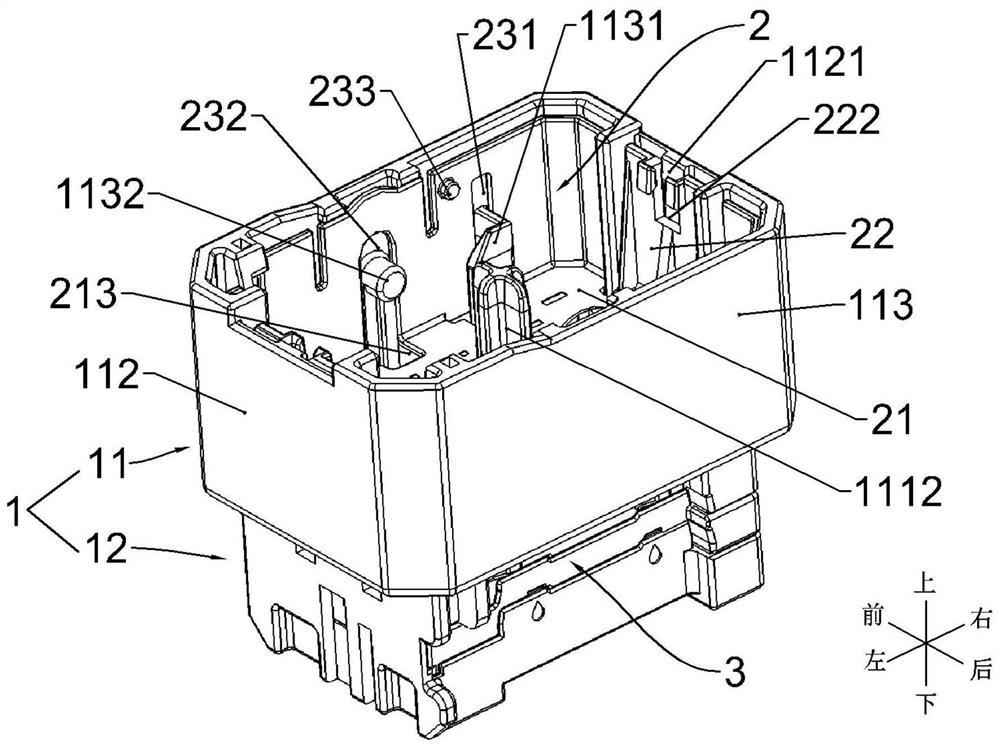

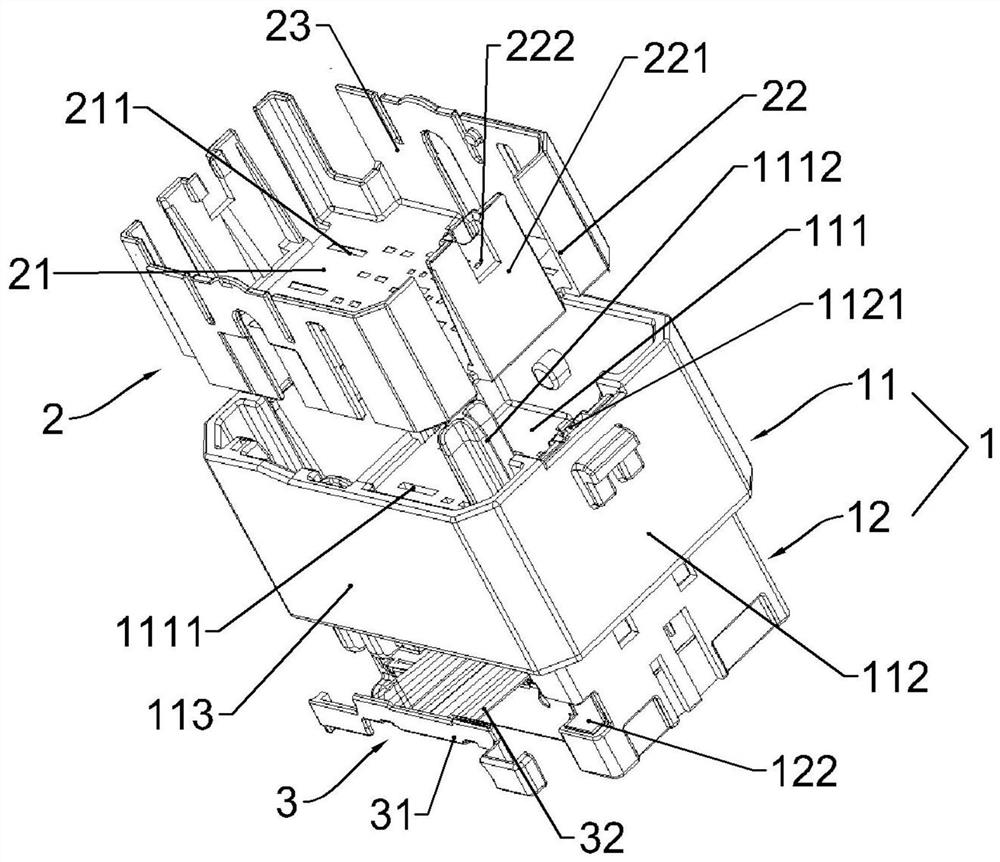

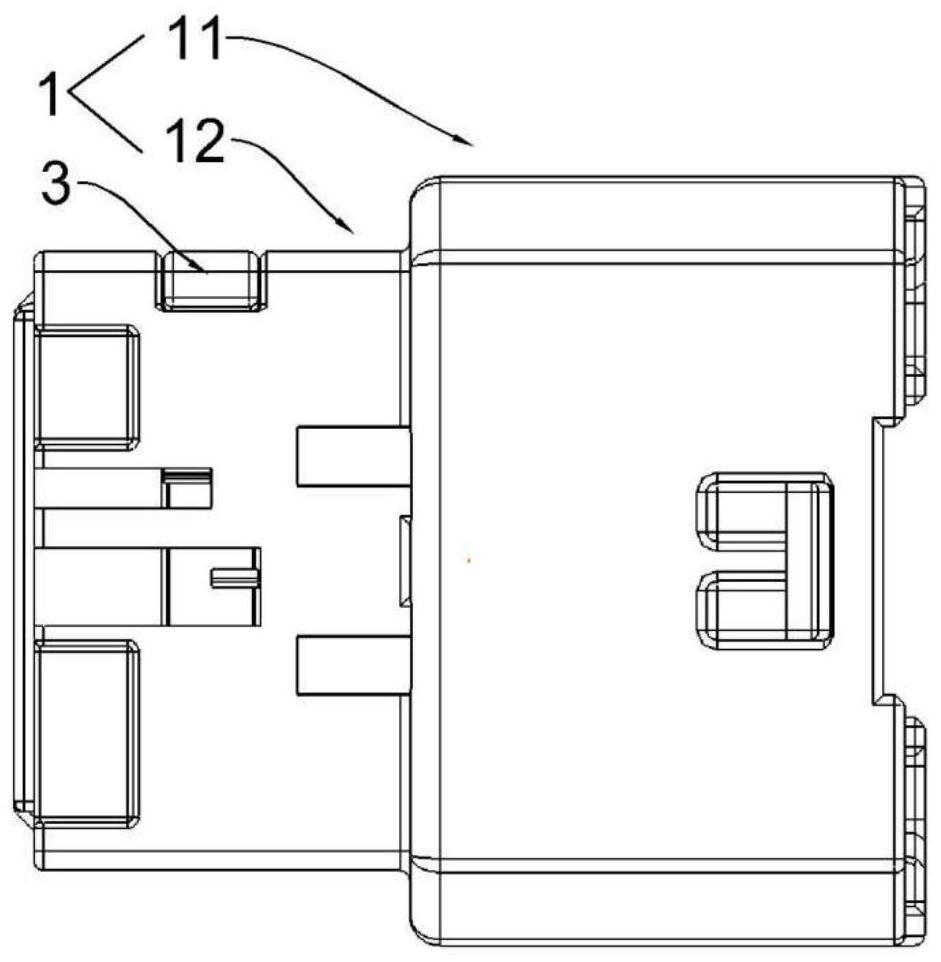

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0033] Such as Figure 1-Figure 8 As shown, a kind of automobile wiring harness connector in this embodiment includes a connector main body 1, and the connector main body 1 includes a connector upper body 11 and a connector lower body 12, and the connector upper body 11 is provided with a first opening facing upwards. Accommodating cavity, the first accommodating cavity has a first bottom wall 111, the lower body 12 of the connector is arranged below the first bottom wall 111, and the interior of the lower body 12 of the connector is provided with a terminal installation cavity, and the terminal installation cavity has a terminal installation bottom wall 121 , the terminal installation bottom wall 121 is provided with a plurality of terminal installation holes for installing wiring harness terminals, and the positions corresponding to the plurality of terminal instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com