Musical instrument panel surface spraying and drying system

A surface spraying and drying system technology, which is applied to the surface coating liquid device, pretreatment surface, coating, etc., can solve the problem of different drying degrees, and achieve the effect of preventing foreign matter from entering, stable structure, and uniform drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

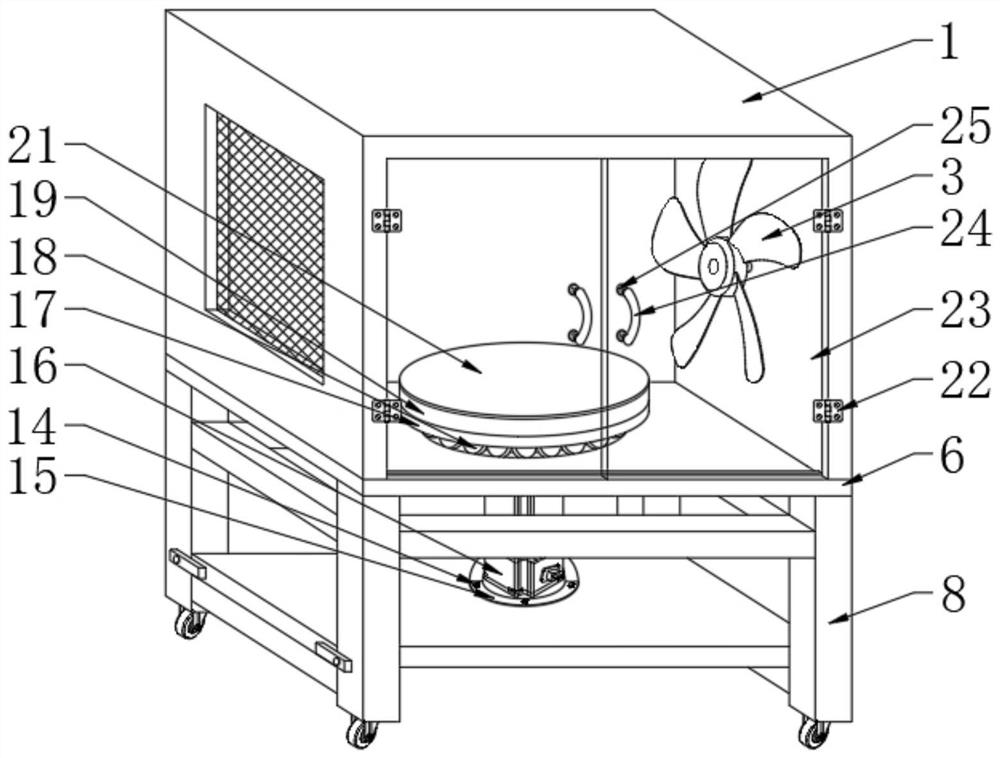

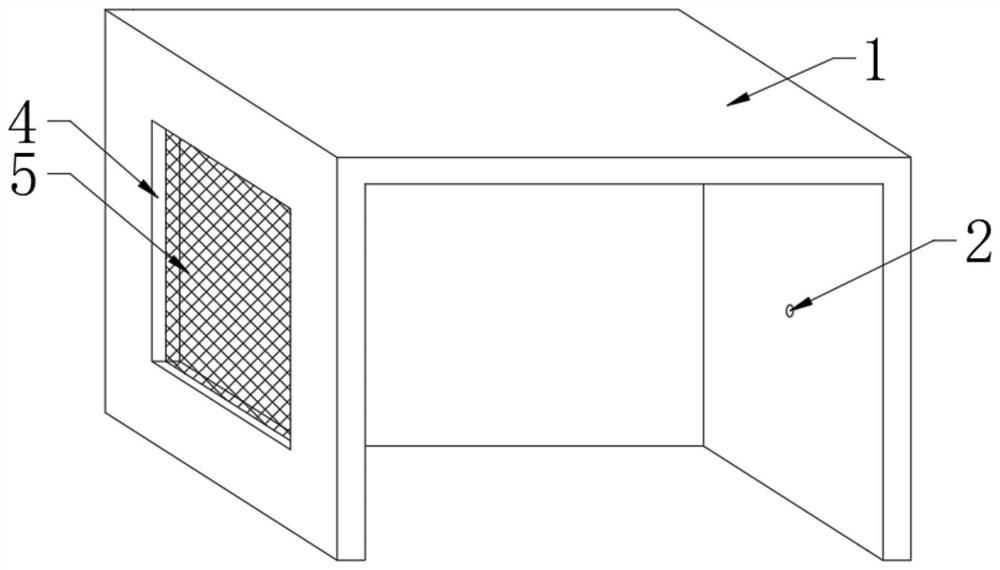

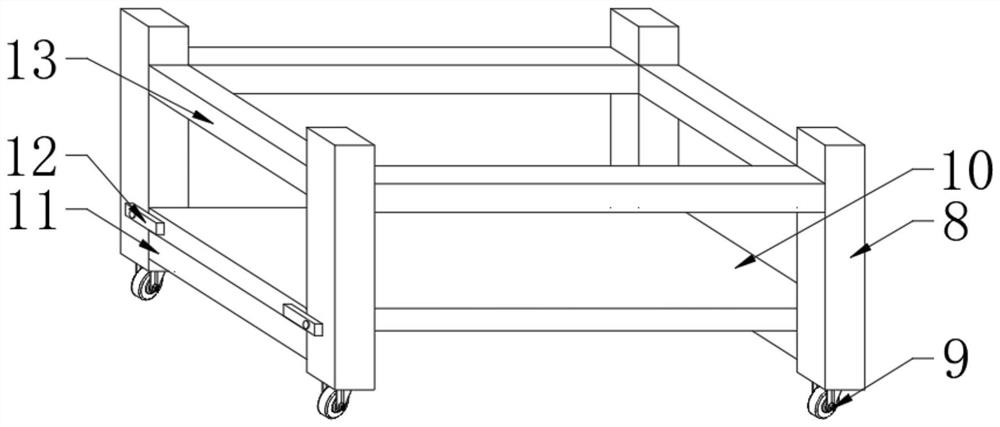

[0031] see Figure 1-6 , a musical instrument panel surface spray drying system, including a protective case 1, the right side wall of the protective case 1 is provided with a first installation hole 2, the inner wall of the first installation hole 2 is movably installed with an exhaust fan 3, the left side wall of the protective case 1 There is a rectangular hole 4, the inner wall of the rectangular hole 4 is fixedly connected with a protective net 5, the bottom of the protective shell 1 is provided with a support plate 6, and the four corners of the lower surface of the support plate 6 are fixedly connected with support legs 8, and the bottom of the support leg 8 is threaded Universal wheels 9 are connected, and the inner wall of the support leg 8 is provided with a mounting plate 10, and the left and right sides of the bottom of the mounting plate 10 are provided with support bars 11, and the front and back sides of the support bar 11 are respectively fixedly connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com