Turbine nanometer sand mill

A sand mill and turbine technology, applied in the field of sand mills, can solve the problem of inability to uniformly convert bulk materials into nano-scale granular materials, unable to increase the output of granular materials of sand mills, and unable to meet the requirements of nano-level Grinding of granular materials and other issues to achieve good rigidity and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

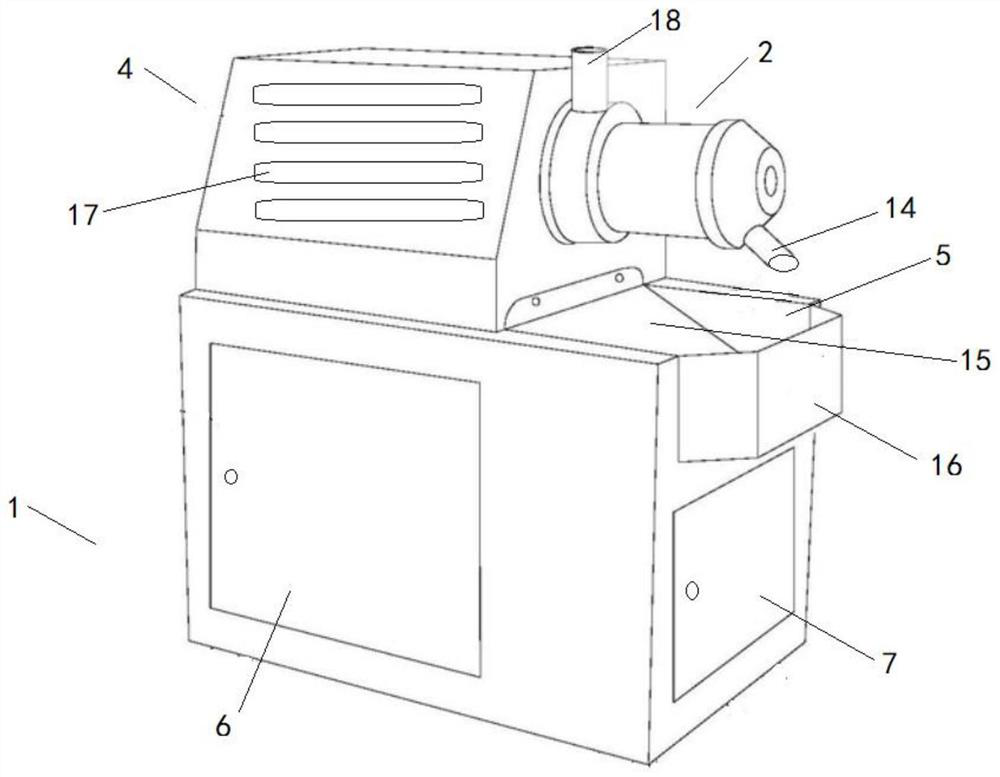

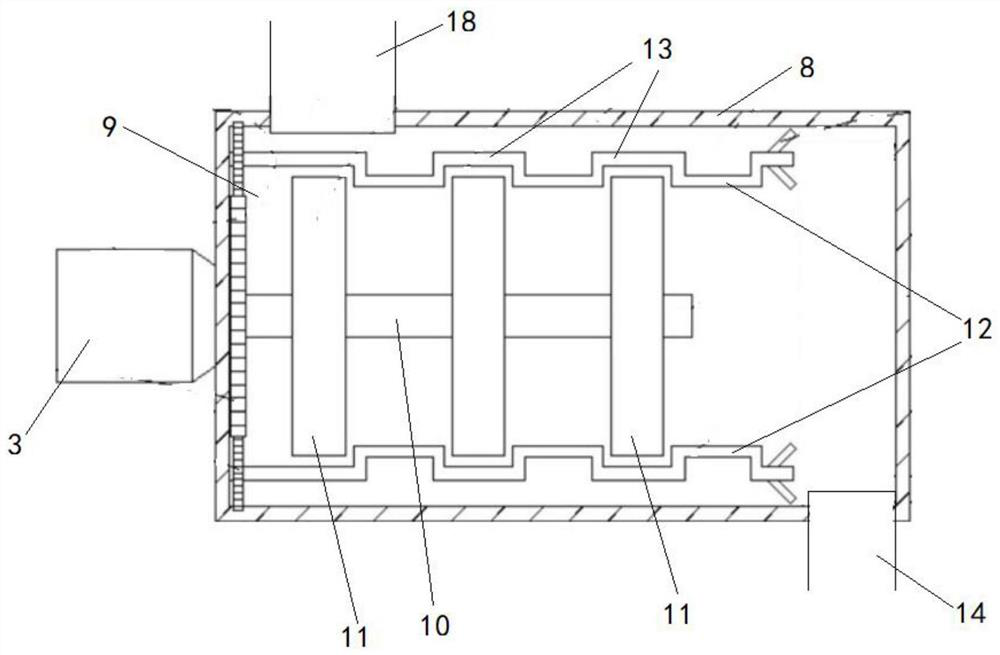

[0022] The turbine nano-sand mill of the present invention will be described in further detail below through specific examples.

[0023] Such as Figure 1 to Figure 2 As shown, it is a schematic diagram of the overall structure of the turbine nano-sand mill and a schematic diagram of the structure of the turbine drum provided by the embodiment of the present invention. The turbine nano-sand mill includes a support box 1, a turbine drum 2, a motor 3, a cooling box 4 and a collection tank 5.

[0024] The support box 1 is in the shape of a hollow cuboid as a whole. A first storage cabinet and a second storage cabinet are arranged inside the support box 1. The first storage cabinet is provided with a first cabinet door 6, and the second storage cabinet is provided with a second storage cabinet. Cabinet door 7; the support box 1 is used as the integral support base of the turbine nano-sand mill, and the first storage cabinet and the second storage cabinet inside it can be used for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com