Crane cabin frame welding tool

A welding tooling and cockpit technology, applied in welding equipment, auxiliary welding equipment, engineering safety devices, etc., can solve problems such as comfortable use experience, reduce device efficiency, and cannot be provided by users, so as to maintain stability and improve use safety. , the effect of improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

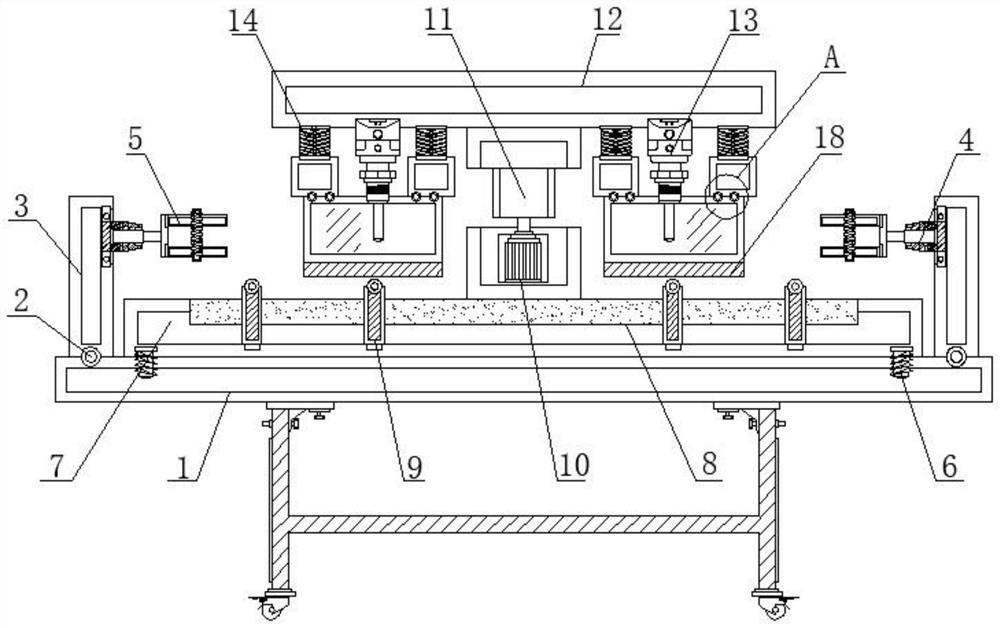

[0024] The technical solutions in the embodiments of the present invention will be apparent from the drawings in the embodiment of the present invention. The following is exemplary, and is intended to be illustrative of the invention, not to be construed as limiting the invention.

[0025] In accordance with the overall configuration of the present invention, the example will be described.

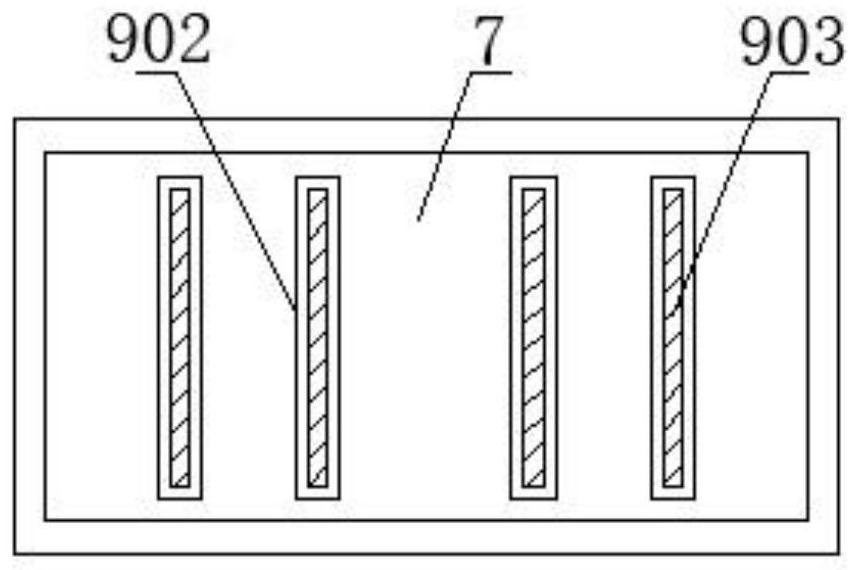

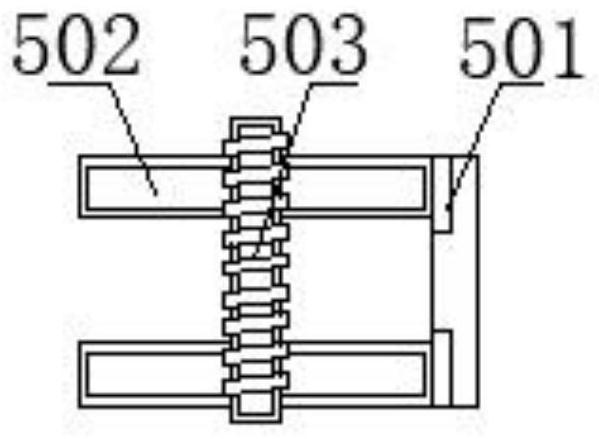

[0026] See Figure 1-4 A crane cabinet frame welding worker, including operating tables 1, holding mechanism 5, support mechanism 9, and welding body 13, and the outer end of the operating table is mounted with a circular shaft 2, and the upper end of the circular shaft 2 is mounted 3, The active rod 3 constitutes a rotation structure through the circular shaft 2 and the operating table 1, and the movable rod 3 is configured as a symmetrical arrangement, and the movable rod 3 mounted in the device can be rotated by the circular shaft 2, which will need to perform The welded frame is placed in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com