Chute device capable of accurately blanking

A chute and blanking technology, which is used in transportation and packaging, conveyor objects, chute, etc., to reduce impact and accurately blank materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific examples.

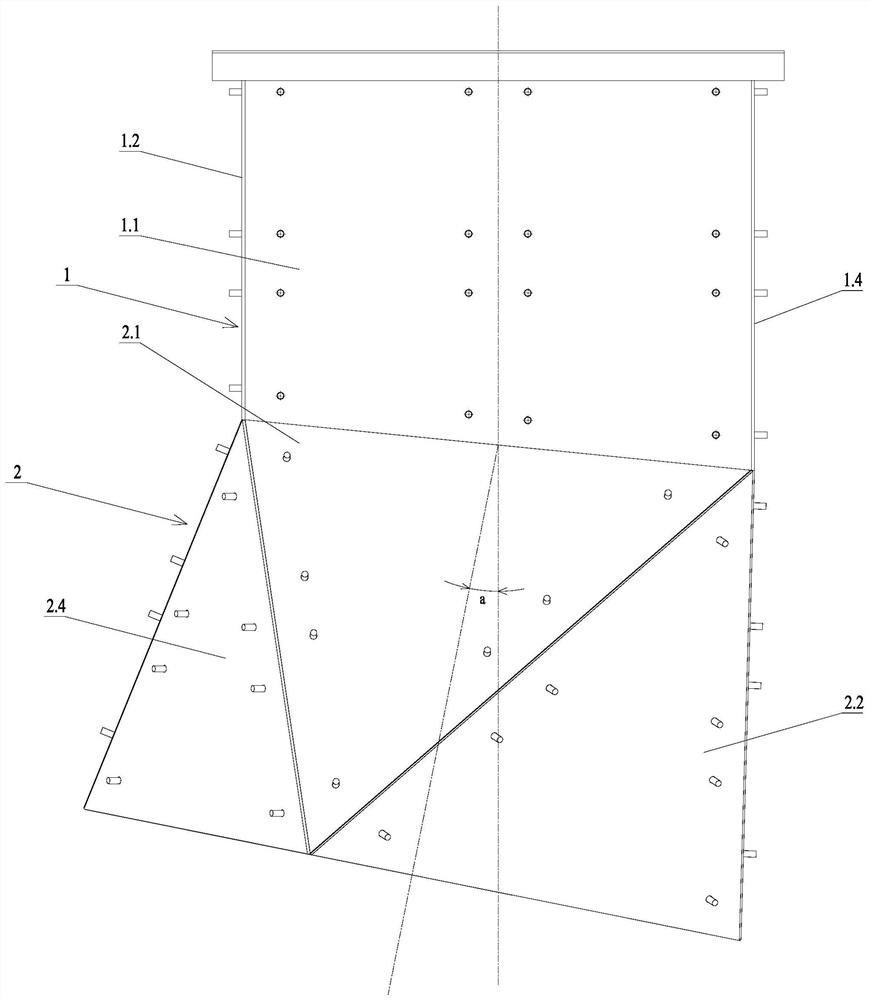

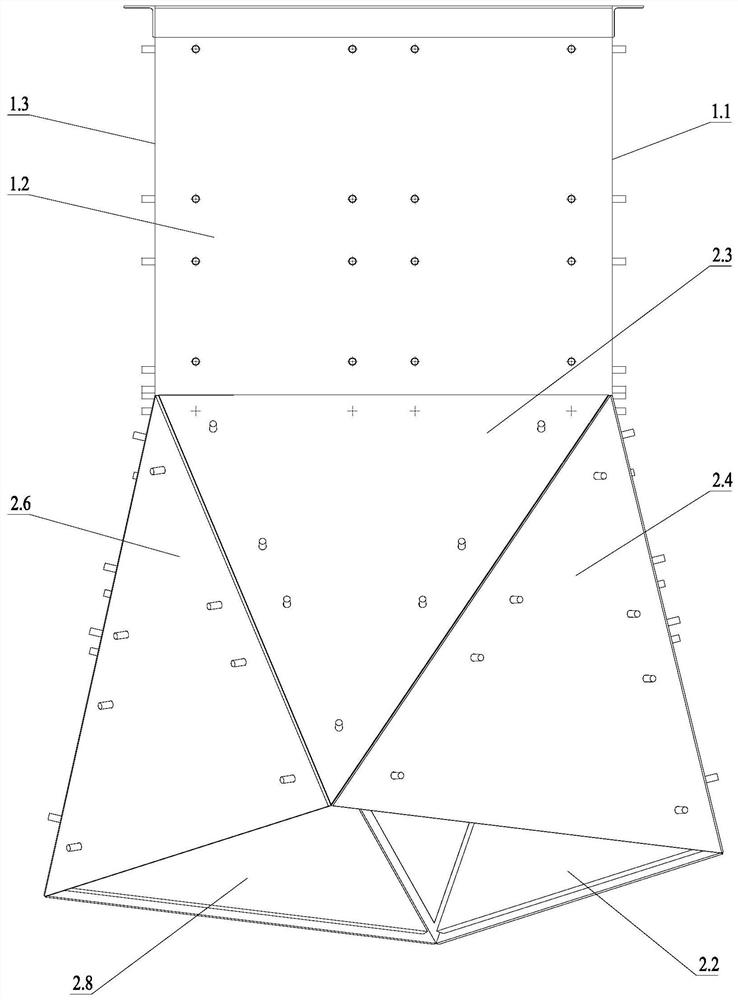

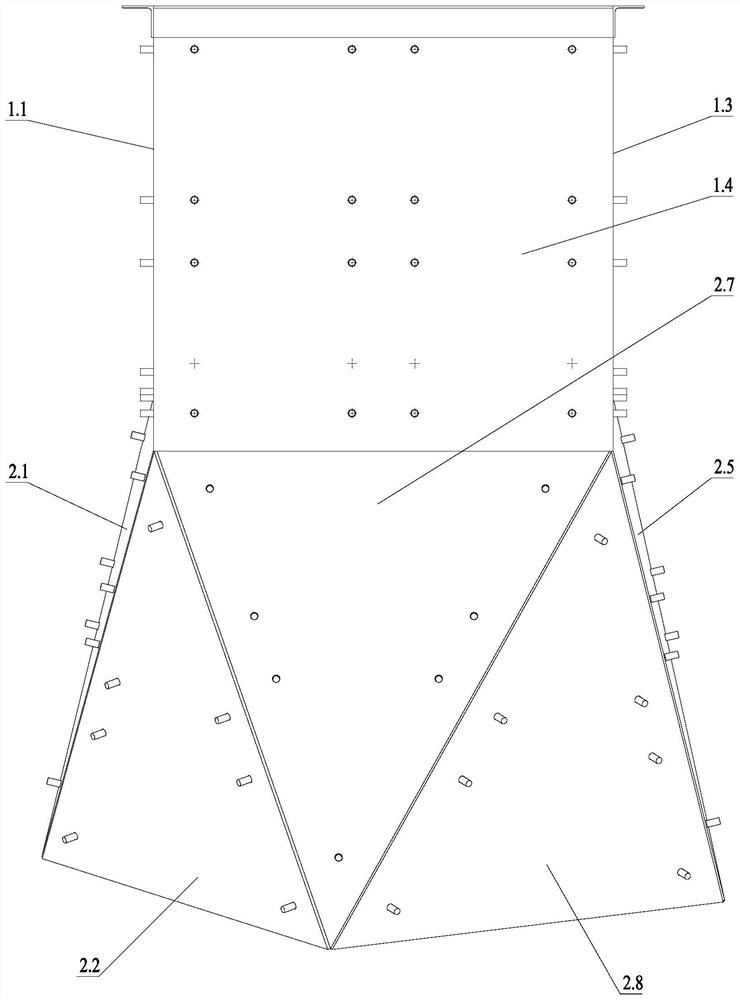

[0019] The chute device capable of precise blanking of the present invention, such as Figure 1-Figure 8 As shown, it includes a chute connection section 1 and a chute buffer steering section 2. A connecting flange is provided on the upper end of the chute connection section 1, and the lower end of the chute connection section 1 is connected to the upper end of the chute buffer steering section 2. The chute The axis of the buffer steering section 2 intersects the axis of the chute connecting section 1 at an acute angle;

[0020] Described chute connection section 1 comprises the integrated chute connection section front panel 1.1, the chute connection section left panel 1.2, the chute connection section rear panel 1.3 and the chute connection section right panel 1.4, the chute connection section front panel 1.1, the chute connection section left panel The panel 1.2, the rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com